Source:Falcon

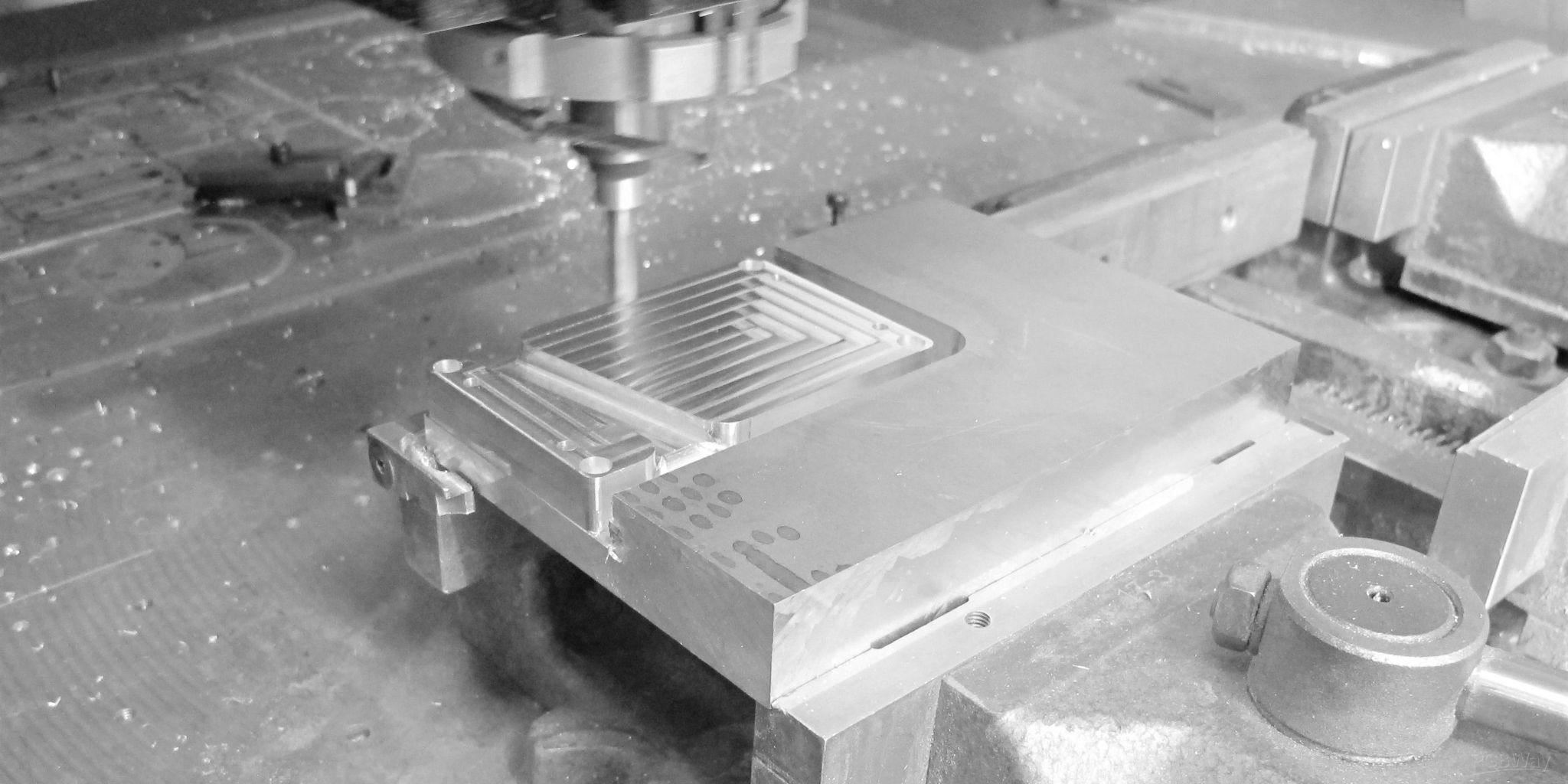

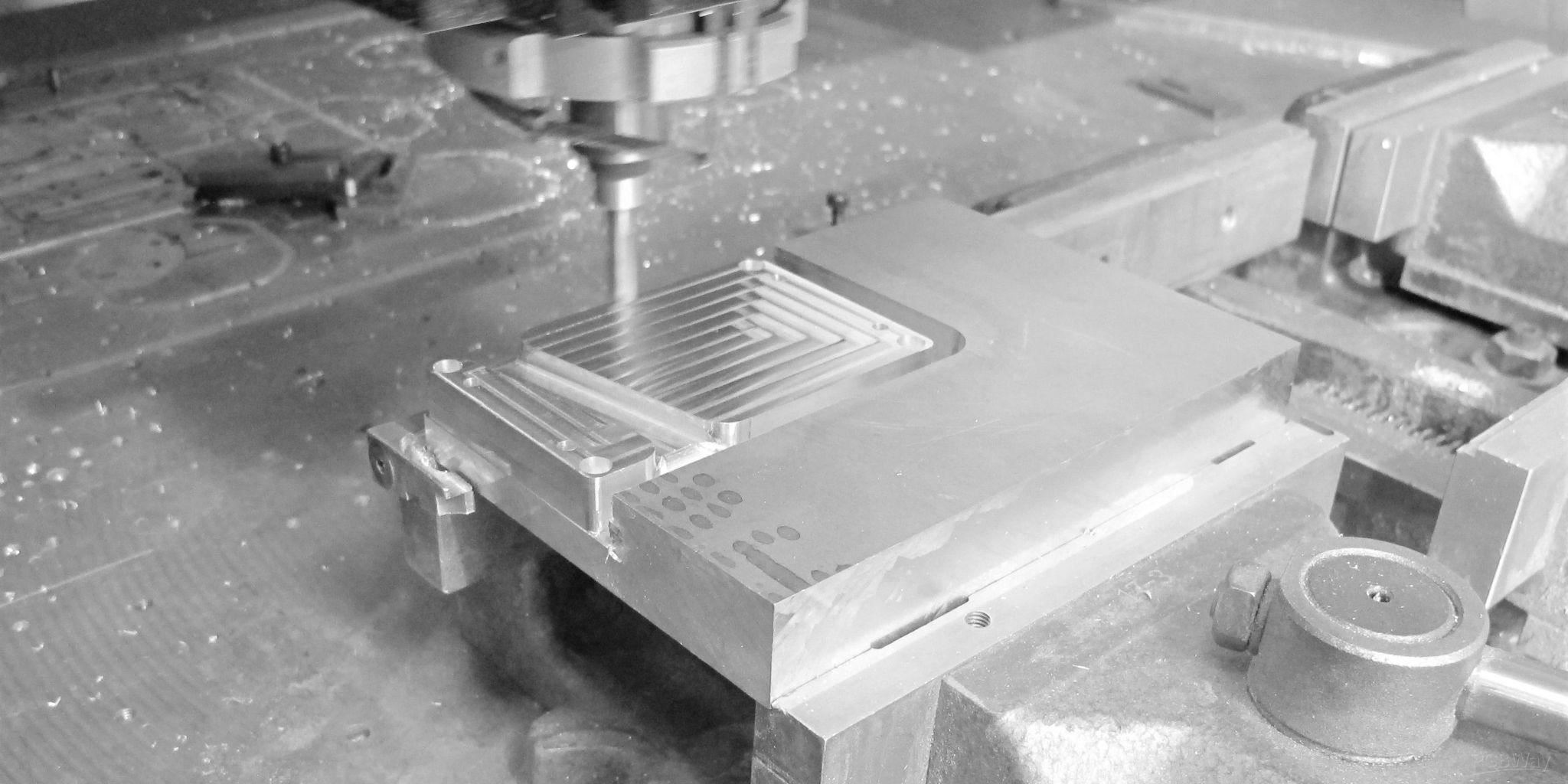

Metal stamping is a process used across a variety of industries in the US and Canada. From the automotive and aerospace industries to medical spaces, the process is integral to the creation of metal components.

Metal stamping allows for the production of goods in large quantities and is a quick process, but, it can be costly.

In this article, we’re going to go over the basics of metal stamping, the types of metal stamping services you may come across, and ways that you can reduce the cost of metal stamping for your business. Keep reading to learn more.

What is CNC Metal Stamping?

CNC Metal stamping is a manufacturing process used to create metal components. It is the conversion of flat metal sheets into a range of shapes. CNC stamping techniques include punching, blanking, embossing, bending, flanging, and coining. Many are carried out by a metal cold stamping machine and the results are flawless.

As a manufacturing process, metal stamping is generally low cost and high speed. The process allows for a high volume of production and is an easy way to create lots of identical metal components. It can be used for both short and long production runs.

The Basics Of Metal Stamping

Most metal stamping companies follow the same processes. A high-quality sheet of flat metal will be placed in a stamping press (the sheet metal may be in coil or blank form).

In the CNC machine, a tool and die surface form the metal into the shape you desire. Depending on what it is you need from the process, there are many types of metal stamping.

Types Of Metal Stamping

There are three common types of metal stamping: progressive die stamping, fourslide stamping, and deep draw stamping. Keep reading to learn more about these common types of metal stamping:

Progressive Die Stamping

Source: gestiondecompras

Progressive die stamping is a form of metal stamping that uses several different stations. Each station has its own function. As the strip metal moves through the progressive stamping press, it unrolls from a coil and into the die press.

Once in the die press, each station of the tool performs its own unique cut, punch, or bend. The idea behind progressive die metal stamping is that each different cut, punch, or bend builds on the previous station’s efforts.

Fourslide Stamping

Fourslide stamping is also referred to as multi-side stamping. It involves four different slides and a horizontal alignment. The process works as four tools work simultaneously on the piece. It allows for multiple intricate cuts at a time to develop intricate components.

As the sheet metal is fed into the fourslide metal stamping machine, it is bent by each tool attached to the machine.

Deep Draw Stamping

Source: Gem Manufacturing

Deep draw metal stamping forms sheet metal into a shape by pulling it into the die through a punch. The term ‘deep drawing’ comes from a step in the process when the depth of the drawn part is larger than its diameter.

This type of metal stamping is used for creating components with several different diameters. It is much more cost-effective than turning processes. It is generally used to create components for the automotive and aerospace industries. It may also be used to create cooking utensils and other cookware.

Benefits and Drawbacks of Metal Stamping

As with any manufacturing process, metal stamping comes with advantages and disadvantages. The advantages of metal stamping are as follows:

Accuracy

The kinds of components made using metal stamping need to be as accurate as possible. This is for the safety and proper functioning of the parts made.

Metal stamping is highly automated, meaning that parts are generated with an incredible level of accuracy. The process uses stamping simulation technology, which marries technology with the stamping process. This process helps to root out flaws before the metal even enters the machine.

It’s Cost-Effective

Other methods of metal component creation have difficulty with smaller and more complex parts. They tend to be more expensive to make, but metal stamping has solved this problem. Small intricate parts can be made easily with the metal stamping process.

Metal stamping, as we have mentioned, is a highly automated process. This means that once the dies are set, there isn’t much left to do. Consequently, fewer engineers are needed, and labour costs are reduced.

This also has a knock-on effect on the price of these components, which can be much lower due to the relative cheapness of the manufacturing process.

Speed

Metal stamping is a relatively quick process, which means manufacturers get a much faster return on investment. Many metal stamping companies have equipment that works at thousands of strokes a minute, making this a high-volume, high-speed process for component production.

Speed, when combined with accuracy, makes for an excellent method of manufacturing and means that companies can bring out new products and technologies much faster.

Flexibility

One of the most incredible parts of metal stamping is the ability to create almost any kind of piece/shape imaginable. From minuscule component parts to highly complex shapes, the metal stamping process can produce it.

Disadvantages Of Metal Stamping

Although there are only a few, metal stamping does have some disadvantages. These include the high cost of presses, the acquisition of dies, and the production of custom metal stamping dies. It is also difficult to change the die if the design needs to be changed during production.

Ways To Reduce Sheet Metal Stamping Costs

While it is considered a cost-effective solution due to its speed, automation, and high-volume ability, metal stamping services can get costly quite quickly. Below, we have summarized a few of the ways you can keep the costs down on metal stamping:

- Use softer raw materials - Harder materials are more difficult to work with and will slow the process down.

- Stick to what you need - When it comes to materials, ensure that you’re using the metal you need and not the most luxurious metal out there. Using luxury metals when they are unnecessary will just increase the cost.

- Optimize the process - Though it is usually cheaper if the part you’re making is touched less, make sure that this is the optimal method of production first.

- Take ‘downstream’ costs into account - This means that while saving on a raw material can be good in the short term, it may impact the overall quality of your part down the line.

- Manufacture higher volumes - The more you make at once, the cheaper the entire process will be.

Services provided to industries

Precision metal stamping has been widely used throughout the industry for decades. When assembling parts and products, several industries use standardized processes, such as:

What metals are best for stamping?

Copper is the most common metal that can have various shapes to meet different application needs, including bronze, nickel, and brass. It has become a popular metal stamping tool due to its diverse properties.

Aerospace

In aerospace, the production processes have strict specifications and regulations. This directive has been adopted for the protection of the passengers and crew, as well as the passengers of the planes and the public. A number of aerospace component companies maintain certification and conformity with various industrial standards, including MilSpec and RoHS. Various metal stamped parts commonly used in aerospace are:

Medical devices

There are numerous guidelines that dictate the manufacturing process of medical devices, similar to those in the aerospace industry. As a result of these exceptionally high standards, both physicians and patients are protected. Metal stampings are commonly used on medical devices such as:

Automotive

In automotive manufacturing, stampers can be utilized to create many structural and functional parts for automobile chassis, electrical components, steering, and other applications. A few examples of car parts used in metal stamping operations are:

Electrical distribution

Professionals working in electrical distribution manufacture many kinds of metal stamping parts to power switchboard distribution boxes, switchboard transformers, and other vital appliances. A few examples are:

Appliances

Steel stamping can also be used for commercial and residential appliances such as: Freezers, Ice machines, Industrial mounts and dispensers, Microwaves, Toaster ovens, Trash compactors and disposals, Ranges, ovens, and cooktops, Refrigerators, Outdoor grills, etc.

What are the best metals for stamping?

Copper is the most common metal and can be formed into a variety of shapes to meet the needs of various applications, such as bronze, nickel, and brass. Because of its diverse properties, it has become a popular metal stamping tool.

What is the purpose of metal stamping?

Metal stamping materials that work well include cups, jars, and shells. This product is smooth, with thin walls, and has many applications ranging from industrial to consumer. Stamp designs are frequently used to manufacture simple metallic lamp components and lamps.

Does stamping cost less than casting?

Stamped dies are less expensive and typically last longer than cast dies, which can be replaced if they are not used frequently. Metal stamps are less expensive per kilogram and are made with stronger materials.

Conclusion

CNC Metal stamping is a process used to create components and parts for a range of industries. It is a generally cost-effective process that is automated and can easily take on high-volume runs. Though it is a cheaper method than other manufacturing processes, metal stamping can get expensive.

To keep costs down, ensure that your initial material is the right material for you, optimize the process for the highest yield at the lowest cost, and ensure you take all downstream costs into account.

Author: Michael

Resources: https://www.triparinc.com/benefits-of-punch-laser-combination-machines/

https://www.pcbway.com/blog/CNC_Machining/Common_Problems_and_Solutions_in_CNC_Machining_3b4c67bc.html

DIY Electronics

DIY Electronics

Arduino

Arduino

Hardware

Hardware

Audio

Audio

Computers & USB

Computers & USB

Breakout Board Projects

Breakout Board Projects

Home Automation

Home Automation

LED Displays & Matrices

LED Displays & Matrices

IoT

IoT

Robotics

Robotics