Andrija Puharich Water Fuel Circuit Voltrolysis VERSION1

This circuit, inspired by Andrija Puharich's innovative design, plays a crucial role in hydrogen production through Voltrolysis, a unique method of water electrolysis that utilizes advanced modulation techniques. The recreation of this circuit by Secure Supplies integrates nano-bubble technology for efficient hydrogen fuel generation.

https://www.patreon.com/securesupplies

Detailed Description of the Circuit:

This PCB (Printed Circuit Board) represents a Hydrogen Hot Rodding Voltrolysis circuit, as patented by Andrija Puharich (U.S. Patent 4,394,230). The design merges several modern components with the fundamentals derived from Nikola Tesla's and Stanley Meyer’s concepts, focusing on hydrogen production through water molecule splitting without conventional high-current electrolysis.

Key Components and Features:

Modulation Section:

CH1 30Hz Offset Adj: This is a control section for fine-tuning the offset frequency at 30Hz, with high and low levels adjustable to +2V and +1.3V, respectively. It ensures the precision of the frequency delivered to the circuit.

Modulation Potentiometer (10K): A key part for adjusting the amplitude of modulation (up to 100%).

ON/OFF Modulation Switch: Allows you to toggle the modulation circuit to control when the circuit drives voltage modulation into the system.

Capacitor (1000µF, 50V):

Provides DC filtering and smoothes out the input power to the circuit. The capacitor helps store energy and then releases it in a controlled manner, preventing ripples in the voltage supply.

Power Input:

120V AC input feeds the primary power through a dedicated transformer setup, eventually supplying regulated power to the key active components. The conversion of AC to DC ensures consistent current flow for driving the electrolysis process.

Active Circuit Components:

MJ11015 and KD305 Transistors: These are power transistors handling large currents and acting as switches or amplifiers within the circuit. These components drive the current needed for the water-splitting process, under controlled modulation. MJ11015 is a high-current transistor, whereas KD305 provides additional power regulation to ensure smooth operation.

10F Non-polar Capacitor: Acts as a resonant capacitor, helping to maintain the ideal frequency for electrolysis. The resonance between this capacitor and the water in the cell allows for efficient voltage application to the water molecules.

BNC Connections:

These connectors allow for easy interfacing with external signal generators or monitoring equipment, crucial for precise voltage and frequency adjustments.

Water Fuel Cell Interface:

The cell connections (S and F) represent the input and output lines where the electrolysis process happens. The design allows for multiple configurations of the electrolysis tubes or plates. Proper adjustment of the modulation and frequency ensures that the resonant frequency is aligned with the natural resonance of water molecules, splitting them into hydrogen and oxygen efficiently.

Resistor Network and Fine Control:

TP22 (test point) allows monitoring of specific voltage levels during operation, ensuring that the circuit performs optimally. Resistors in series provide current limiting and fine-tuning capabilities for balancing the modulation across different stages of the circuit.

Grounding and Safety:

The grounding sections ensure that the circuit remains safe during operation, dissipating excess current and voltage spikes effectively.

Working Mechanism:

The Voltrolysis process works by sending modulated electrical signals at specific frequencies into the water fuel cell. The modulation, controlled through the frequency offset (30Hz in this case), aligns with the water's molecular resonance frequency. Instead of brute-force electrolysis using high current, this technique efficiently separates water molecules into hydrogen and oxygen using less energy by inducing nano bubbles at a molecular level, improving the hydrogen production rate.

The MJ11015 and KD305 transistors handle the switching of high currents required to generate the necessary fields. They act in conjunction with the modulation to control the timing and strength of the pulses sent to the water fuel cell. The result is an efficient system capable of generating hydrogen with reduced power consumption compared to traditional methods.

Practical Applications:

Hydrogen Fuel Production: This circuit is ideal for small-scale hydrogen production, supporting clean energy initiatives.

Renewable Energy Systems: With the growing focus on alternative energy, this circuit can be integrated into hydrogen fuel cells or energy storage systems for vehicles or stationary power units.

Scientific Research: It provides a robust platform for researchers working on water electrolysis or experimenting with nano-bubble technologies for hydrogen generation.

Conclusion:

The recreation of Andrija Puharich's Voltrolysis circuit by Secure Supplies has enhanced its functionality with modern components and modulation techniques, providing an efficient, low-power alternative for hydrogen production. This circuit board is a crucial part of future hydrogen fuel systems, contributing to advancements in clean energy solutions.

The circuit is ideal for those looking to explore hydrogen fuel technologies, experiment with water electrolysis, or develop systems for renewable energy generation.

Daniel's kind-hearted approach and dedication to a cleaner energy future deserve recognition and support.

By supporting his work, you join in the journey toward a sustainable future. Godspeed, Daniel Donatelli!

Andrija Puharich Water Fuel Circuit Voltrolysis VERSION1

*PCBWay community is a sharing platform. We are not responsible for any design issues and parameter issues (board thickness, surface finish, etc.) you choose.

- Comments(3)

- Likes(2)

-

Lucas Martins

May 18,2025

Lucas Martins

May 18,2025

-

Daniel Donatelli

Nov 03,2024

Daniel Donatelli

Nov 03,2024

- 1 USER VOTES

- YOUR VOTE 0.00 0.00

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

10design

-

10usability

-

10creativity

-

10content

More by Daniel Donatelli

More by Daniel Donatelli

-

Stanley A Meyer VIC Voltage intensifier circuit transformer board v1.8 updated jan 11 2021

Stanley A Meyer VIC Voltage intensifier transformer board Join Support help change the World https:/...

Stanley A Meyer VIC Voltage intensifier circuit transformer board v1.8 updated jan 11 2021

Stanley A Meyer VIC Voltage intensifier transformer board Join Support help change the World https:/...

-

STANLEY A MEYER LES BANKI AUTO START AUTO WATER FUEL REFILL

STANLEY A MEYER LES BANKI AUTO START AUTO WATER FUEL REFILLJoin Support help change the World https:...

STANLEY A MEYER LES BANKI AUTO START AUTO WATER FUEL REFILL

STANLEY A MEYER LES BANKI AUTO START AUTO WATER FUEL REFILLJoin Support help change the World https:...

-

Stanley A Meyer Gated Pulse Frequency Generator K3 with DB 37 updated 060622

Stanley A Meyer Gated Pulse Frequency Generator K3 with DB 37 to suit matrix vic main board Join Sup...

Stanley A Meyer Gated Pulse Frequency Generator K3 with DB 37 updated 060622

Stanley A Meyer Gated Pulse Frequency Generator K3 with DB 37 to suit matrix vic main board Join Sup...

-

Stanley A Meyer K2 Variable Pulse Frequency Generator GMS Vic Matrix PCB Gerber

Stanley A Meyer K2 Variable Pulse Frequency Generator GMS Vic Matrix PCBGerberJoin Support help chan...

Stanley A Meyer K2 Variable Pulse Frequency Generator GMS Vic Matrix PCB Gerber

Stanley A Meyer K2 Variable Pulse Frequency Generator GMS Vic Matrix PCBGerberJoin Support help chan...

-

Hyduino Stim Stimulator circuit board Ms EMS ECU

Hyduino Stim Stimulator circuit board Ms EMS ECUJoin Support help change the World https://www.patre...

Hyduino Stim Stimulator circuit board Ms EMS ECU

Hyduino Stim Stimulator circuit board Ms EMS ECUJoin Support help change the World https://www.patre...

-

Stanley A Meyer VIC Daughter Board Driver Transistor Circuit board Version 1

Stanley A Meyer VIC Daughter Board Driver Transistor Circuit board Version 1 Updated 28th Sept 2021 ...

Stanley A Meyer VIC Daughter Board Driver Transistor Circuit board Version 1

Stanley A Meyer VIC Daughter Board Driver Transistor Circuit board Version 1 Updated 28th Sept 2021 ...

-

Stanley A Meyer VIC Daughter Board Driver USed with Variac EEC eleectron eextrract & chokes

Stanley A Meyer VIC Daughter Board Driver USed with Variac EEC eleectron extrract & chokes can d...

Stanley A Meyer VIC Daughter Board Driver USed with Variac EEC eleectron eextrract & chokes

Stanley A Meyer VIC Daughter Board Driver USed with Variac EEC eleectron extrract & chokes can d...

-

Stanley A Meyer Fuel Line Insert WFC Nano Bubble Water Fuel Cell V3

Stanley A Meyer WFC Nano Bubble Water Fuel Cell V3 Barbed Fuel Line insert Stanley a Meyer WFC Nano ...

Stanley A Meyer Fuel Line Insert WFC Nano Bubble Water Fuel Cell V3

Stanley A Meyer WFC Nano Bubble Water Fuel Cell V3 Barbed Fuel Line insert Stanley a Meyer WFC Nano ...

-

Stanley A Meyer Nano Bubble Water Fuel Cell WFC Parts 2026 V2

Stanley a Meyer WFC Nano Bubble Water Fuel Cell Single Cell 2026Stanley a Meyer Single Cell 2026This...

Stanley A Meyer Nano Bubble Water Fuel Cell WFC Parts 2026 V2

Stanley a Meyer WFC Nano Bubble Water Fuel Cell Single Cell 2026Stanley a Meyer Single Cell 2026This...

-

Stanley a Meyer WFC Nano Bubble Water Fuel Cell Single Cell 2026

Stanley a Meyer Single Cell 2026This is a work to make it faster easier for every one to get the cel...

Stanley a Meyer WFC Nano Bubble Water Fuel Cell Single Cell 2026

Stanley a Meyer Single Cell 2026This is a work to make it faster easier for every one to get the cel...

-

2025 Stanley A Meyer Egan Half Bridge Switch VOLTROLYSIS

2025 Stanley A Meyer Egan Half Bridge Switch VOLTROLYSISJoin the Builder LevelBy joining the Builder...

2025 Stanley A Meyer Egan Half Bridge Switch VOLTROLYSIS

2025 Stanley A Meyer Egan Half Bridge Switch VOLTROLYSISJoin the Builder LevelBy joining the Builder...

-

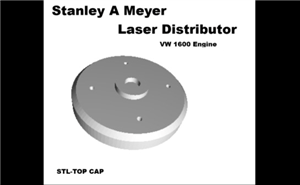

Stanley A Meyer vw 1600 Cap Laser Distributor

Stanley A Meyer vw 1600 Cap Laser DistributorVideo https://youtu.be/XQd8zwEA4LE?si=dpG4jgLsHhYTkX5cJ...

Stanley A Meyer vw 1600 Cap Laser Distributor

Stanley A Meyer vw 1600 Cap Laser DistributorVideo https://youtu.be/XQd8zwEA4LE?si=dpG4jgLsHhYTkX5cJ...

-

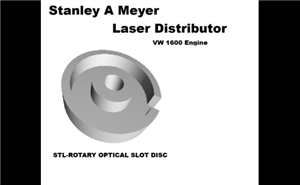

Stanley A Meyer vw 1600 STL-ROTARY OPTICAL SLOT DISC

Stanley A Meyer vw 1600 STL-ROTARY OPTICAL SLOT DISCVideo https://youtu.be/XQd8zwEA4LE?si=dpG4jgLsHh...

Stanley A Meyer vw 1600 STL-ROTARY OPTICAL SLOT DISC

Stanley A Meyer vw 1600 STL-ROTARY OPTICAL SLOT DISCVideo https://youtu.be/XQd8zwEA4LE?si=dpG4jgLsHh...

-

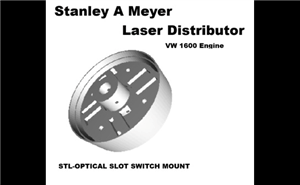

Stanley A Meyer vw 1600 STL-OPTICAL SLOT SWITCH MOUNT

Stanley A Meyer vw 1600 STL-OPTICAL SLOT SWITCH MOUNTVideo https://youtu.be/XQd8zwEA4LE?si=dpG4jgLsH...

Stanley A Meyer vw 1600 STL-OPTICAL SLOT SWITCH MOUNT

Stanley A Meyer vw 1600 STL-OPTICAL SLOT SWITCH MOUNTVideo https://youtu.be/XQd8zwEA4LE?si=dpG4jgLsH...

-

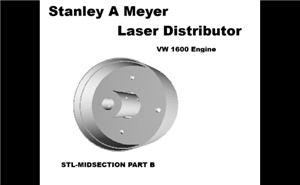

Stanley Meyer Laser VW 1600 Buggy Distributor STL-MIDSECTION PART B

Stanley Meyer Laser VW 1600 Buggy Distributor STL-MIDSECTION PART BVideo https://youtu.be/XQd8zwEA4L...

Stanley Meyer Laser VW 1600 Buggy Distributor STL-MIDSECTION PART B

Stanley Meyer Laser VW 1600 Buggy Distributor STL-MIDSECTION PART BVideo https://youtu.be/XQd8zwEA4L...

-

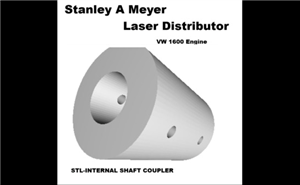

Stanley Meyer Laser VW 1600 Buggy Distributor STL-INTERNAL SHAFT COUPLER

Stanley Meyer Laser VW 1600 Buggy Distributor STL-INTERNAL SHAFT COUPLER Video https://youtu.be/XQd8...

Stanley Meyer Laser VW 1600 Buggy Distributor STL-INTERNAL SHAFT COUPLER

Stanley Meyer Laser VW 1600 Buggy Distributor STL-INTERNAL SHAFT COUPLER Video https://youtu.be/XQd8...

-

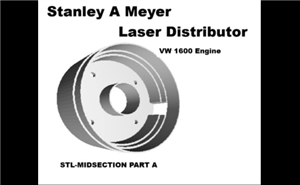

Stanley Meyer Laser VW 1600 Buggy Distributor STL-MIDSECTION PART A

Stanley Meyer Laser VW 1600 Buggy STL-MIDSECTION PART A Video https://youtu.be/XQd8zwEA4LE?si=dpG4jg...

Stanley Meyer Laser VW 1600 Buggy Distributor STL-MIDSECTION PART A

Stanley Meyer Laser VW 1600 Buggy STL-MIDSECTION PART A Video https://youtu.be/XQd8zwEA4LE?si=dpG4jg...

-

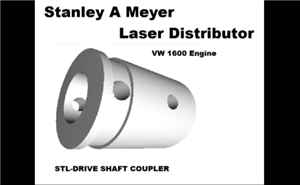

Stanley Meyer Laser VW 1600 Buggy Distributor STL-DRIVE SHAFT COUPLER (1)

Stanley Meyer Laser VW 1600 Buggy Distributor Video https://youtu.be/XQd8zwEA4LE?si=dpG4jgLsHhYTkX5c...

Stanley Meyer Laser VW 1600 Buggy Distributor STL-DRIVE SHAFT COUPLER (1)

Stanley Meyer Laser VW 1600 Buggy Distributor Video https://youtu.be/XQd8zwEA4LE?si=dpG4jgLsHhYTkX5c...

-

-

mammoth-3D SLM Voron Toolhead – Manual Drill & Tap Edition

251 0 0 -

-

AEL-2011 Power Supply Module

776 0 2 -

AEL-2011 50W Power Amplifier

643 0 2 -

-

-

Custom Mechanical Keyboard

838 0 0 -

Tester for Touch Screen Digitizer without using microcontroller

460 2 2 -

Audio reactive glow LED wristband/bracelet with NFC / RFID-Tags

407 0 1 -

-