SukkoPera

ITALY • + Follow

Edit Project

Description

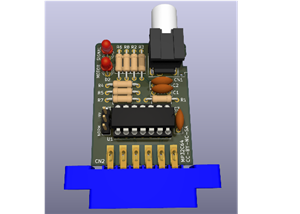

OpenC64Cart V2 (8K)

OpenC64Cart is an Open Hardware 8 KB Cartridge for the Commodore 64.

For more information, please visit github.com/SukkoPera/OpenC64Cart.

Jan 04,2018

10,312 views

OpenC64Cart V2 (8K)

2 Layers PCB 50.8 x 58.42 mm FR-4, 1.6 mm, 1, HASL with lead, Blue Solder Mask, White silkscreen

10312

36

20

10.00 (2)

Published: Jan 04,2018

Standard PCB

Download Gerber file 257

BOM(Bill of materials)

Centroid file

Purchase

Donation Received ($)

PCBWay Donate 10% cost To Author

File Last Updated: 2023/08/02 (GMT+8)

File update record

2023-08-0214:27:04

Centroid file is updated.

Only PCB

PCB+Assembly

*PCBWay community is a sharing platform. We are not responsible for any design issues and parameter issues (board thickness, surface finish, etc.) you choose.

Copy this HTML into your page to embed a link to order this shared project

Copy

Under the

Attribution-ShareAlike (CC BY-SA)

License.

- Comments(20)

- Likes(36)

Upload photo

You can only upload 5 files in total. Each file cannot exceed 2MB. Supports JPG, JPEG, GIF, PNG, BMP

0 / 10000

It looks like you have not written anything. Please add a comment and try again.

You can upload up to 5 images!

Image size should not exceed 2MB!

File format not supported!

View More

-

Arbe Lehmann

Apr 24,2025

Arbe Lehmann

Apr 24,2025

-

Engineer

Apr 03,2025

Engineer

Apr 03,2025

-

Kyle Messineo

Feb 05,2025

Kyle Messineo

Feb 05,2025

-

Mattias Hedberg

Jul 03,2023

Mattias Hedberg

Jul 03,2023

-

Mr. Marsupial

Jan 25,2023

Mr. Marsupial

Jan 25,2023

-

Xavier Lario

Jan 23,2022

Xavier Lario

Jan 23,2022

-

Peter Ivanov

Oct 25,2021

Peter Ivanov

Oct 25,2021

-

Clive Chamberlain

May 03,2021

Clive Chamberlain

May 03,2021

-

sausage

Jan 22,2021

sausage

Jan 22,2021

-

Kalle Lampila

Dec 14,2020

Kalle Lampila

Dec 14,2020

-

ngr

Sep 24,2020

ngr

Sep 24,2020

-

Fox Cunning

Aug 19,2020

Fox Cunning

Aug 19,2020

-

Engineer

Jun 28,2020

Engineer

Jun 28,2020

-

DRRB

Jun 15,2020

DRRB

Jun 15,2020

-

Herve Warin

May 14,2020

Herve Warin

May 14,2020

-

Wesley Storms

Apr 24,2020

Wesley Storms

Apr 24,2020

-

Filippo Bergamasco

Apr 18,2020

Filippo Bergamasco

Apr 18,2020

-

Jeremy Kuhne

Mar 23,2020

Jeremy Kuhne

Mar 23,2020

-

Nelson Berrios

Mar 20,2020

Nelson Berrios

Mar 20,2020

-

Mr Eddie Bannister

Mar 20,2020

Mr Eddie Bannister

Mar 20,2020

-

Csaba Toth

Feb 29,2020

Csaba Toth

Feb 29,2020

-

Commodore Bench

Feb 24,2020

Commodore Bench

Feb 24,2020

-

Martin Weber

Oct 30,2019

Martin Weber

Oct 30,2019

-

Andrii Moroz

Oct 21,2019

Andrii Moroz

Oct 21,2019

-

Freddy Maes

Sep 09,2019

Freddy Maes

Sep 09,2019

-

Galvan

Sep 08,2019

Galvan

Sep 08,2019

-

Giuseppe Giu MacGyver

Jul 10,2019

Giuseppe Giu MacGyver

Jul 10,2019

-

pablocastine

May 03,2019

pablocastine

May 03,2019

-

Mike Hawkey

Jan 29,2019

Mike Hawkey

Jan 29,2019

-

James

Oct 08,2018

James

Oct 08,2018

-

Peter Holly

Sep 19,2018

Peter Holly

Sep 19,2018

-

Shazz

Aug 02,2018

Shazz

Aug 02,2018

-

Juan Manuel Vazquez

Jul 20,2018

Juan Manuel Vazquez

Jul 20,2018

-

Darren Brocklebank

Jun 30,2018

Darren Brocklebank

Jun 30,2018

-

HaPe

Mar 08,2018

HaPe

Mar 08,2018

-

Abbyss

Jan 07,2018

Abbyss

Jan 07,2018

View More

VOTING

2 votes

- 2 USER VOTES

10.00

- YOUR VOTE 0.00 0.00

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

Design

1/4

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

Usability

2/4

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

Creativity

3/4

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

Content

4/4

-

10design

-

10usability

-

10creativity

-

10content

10.00

-

10design

-

10usability

-

10creativity

-

10content

10.00

More by SukkoPera

More by SukkoPera

-

Hannes512 - 512 kB RAM Expansion for the Commodore 16/+4

Hannes512 is an Open Hardware internal 512 kB RAM Expansion board for the Commodore 16.For more info...

Hannes512 - 512 kB RAM Expansion for the Commodore 16/+4

Hannes512 is an Open Hardware internal 512 kB RAM Expansion board for the Commodore 16.For more info...

-

ReSeed v2 - SIDcard for the Commodore 16/Plus 4

ReSeed is an expansion card for the Commodore 16 and Plus/4 computers that allows interfacing the co...

ReSeed v2 - SIDcard for the Commodore 16/Plus 4

ReSeed is an expansion card for the Commodore 16 and Plus/4 computers that allows interfacing the co...

-

WheelOfJoy - Commodore 16/116/+4 8-Player Joystick Adapter

WheelOfJoy is an Open Hardware 8-player joystick adapter for the Commodore 16 and Plus/4.The origina...

WheelOfJoy - Commodore 16/116/+4 8-Player Joystick Adapter

WheelOfJoy is an Open Hardware 8-player joystick adapter for the Commodore 16 and Plus/4.The origina...

-

LittleSixteen V3 - Improved Commodore 16 Mainboard

LittleSixteen is an Open Hardware remake of the Commodore 16 home computer, featuring many improveme...

LittleSixteen V3 - Improved Commodore 16 Mainboard

LittleSixteen is an Open Hardware remake of the Commodore 16 home computer, featuring many improveme...

-

OldPromAdapter V1

OldPromAdapter is an Open Hardware Adapter that allows replacing 82s126, 82s129 and 82s131 PROMs wit...

OldPromAdapter V1

OldPromAdapter is an Open Hardware Adapter that allows replacing 82s126, 82s129 and 82s131 PROMs wit...

-

OpenC64KernalCart V1

This cartridge allows replacing the KERNAL (i.e.: operating system) of a Commodore C64 computer with...

OpenC64KernalCart V1

This cartridge allows replacing the KERNAL (i.e.: operating system) of a Commodore C64 computer with...

-

OpenAmiga600RamExpansion V1

OpenAmiga600RamExpansion is an Open Hardware 1 MB Chip RAM Expansion for the Commodore Amiga 600 Com...

OpenAmiga600RamExpansion V1

OpenAmiga600RamExpansion is an Open Hardware 1 MB Chip RAM Expansion for the Commodore Amiga 600 Com...

-

MechBoard16 - Mechanical Keyboard for the Commodore 16 and LittleSixteen Computers

MechBoard16 is a mechanical keyboard for the Commodore 16.For more information please visit the GitH...

MechBoard16 - Mechanical Keyboard for the Commodore 16 and LittleSixteen Computers

MechBoard16 is a mechanical keyboard for the Commodore 16.For more information please visit the GitH...

-

LittleSixteen V4 - Build your own Commodore 16/Plus4!

LittleSixteen is an Open Hardware remake of the Commodore 16, 116 and Plus/4 home computers, featuri...

LittleSixteen V4 - Build your own Commodore 16/Plus4!

LittleSixteen is an Open Hardware remake of the Commodore 16, 116 and Plus/4 home computers, featuri...

-

DatassetteAudioAdapter - Replace the Commodore Datassette with any audio source!

DatassetteAudioAdapter is a simple adapter that allows connecting any audio source to the Datassette...

DatassetteAudioAdapter - Replace the Commodore Datassette with any audio source!

DatassetteAudioAdapter is a simple adapter that allows connecting any audio source to the Datassette...

-

MP32C64 - Replace the Commodore Datassette with any audio source!

MP32C64 is a simple adapter that allows connecting any audio source to the Datassette port of a Comm...

MP32C64 - Replace the Commodore Datassette with any audio source!

MP32C64 is a simple adapter that allows connecting any audio source to the Datassette port of a Comm...

-

NessieSoup - Super Nintendo Controller Adapter for the Commodore 64, VIC-20 and Plus/4

NessieSoup is a simple adapter that allows connecting Super Nintendo controllers to a Commodore 64, ...

NessieSoup - Super Nintendo Controller Adapter for the Commodore 64, VIC-20 and Plus/4

NessieSoup is a simple adapter that allows connecting Super Nintendo controllers to a Commodore 64, ...

-

Plus42Wire - I2C Bus Interface for the Commodore 16/116/+4

Plus42Wire is an I2C (Inter-Integrated Circuit, sometimes known as 2-Wire) Interface for the Commodo...

Plus42Wire - I2C Bus Interface for the Commodore 16/116/+4

Plus42Wire is an I2C (Inter-Integrated Circuit, sometimes known as 2-Wire) Interface for the Commodo...

-

Plus4i8255 V2 - Intel 8255 Interface for the Commodore 16, 116 and Plus/4

Plus4i8255 is an Intel 8255 Interface for the Commodore 16, 116 and Plus/4.For more information plea...

Plus4i8255 V2 - Intel 8255 Interface for the Commodore 16, 116 and Plus/4

Plus4i8255 is an Intel 8255 Interface for the Commodore 16, 116 and Plus/4.For more information plea...

-

PiRTOII - Flash multicart for the Mattel Intellivision - Original Pico Version

PiRTO II if a flash multicart for the Mattel Intellivision based on the Raspberry Pico.This version ...

PiRTOII - Flash multicart for the Mattel Intellivision - Original Pico Version

PiRTO II if a flash multicart for the Mattel Intellivision based on the Raspberry Pico.This version ...

-

Hannes256 - 256 kB RAM Expansion for the Commodore 16/+4

Hannes256 is an Open Hardware internal 256 kB RAM Expansion board for the Commodore 16.For more info...

Hannes256 - 256 kB RAM Expansion for the Commodore 16/+4

Hannes256 is an Open Hardware internal 256 kB RAM Expansion board for the Commodore 16.For more info...

-

Fixteen V3 - Internal 64 kB RAM Expansion for the Commodore 16

Fixteen is an Open Hardware internal 64 kB RAM Expansion board for the Commodore 16.For more informa...

Fixteen V3 - Internal 64 kB RAM Expansion for the Commodore 16

Fixteen is an Open Hardware internal 64 kB RAM Expansion board for the Commodore 16.For more informa...

-

SoundX - An AdLib card for your Commodore 16/116/+4!

SoundX is an Open Hardware sound card for the Commodore 16, 116 and Plus/4 home computers based on t...

SoundX - An AdLib card for your Commodore 16/116/+4!

SoundX is an Open Hardware sound card for the Commodore 16, 116 and Plus/4 home computers based on t...

You may also like

-

-

mammoth-3D SLM Voron Toolhead – Manual Drill & Tap Edition

207 0 0 -

-

AEL-2011 Power Supply Module

730 0 2 -

AEL-2011 50W Power Amplifier

607 0 2 -

-

-

Custom Mechanical Keyboard

812 0 0 -

Tester for Touch Screen Digitizer without using microcontroller

438 2 2 -

Audio reactive glow LED wristband/bracelet with NFC / RFID-Tags

391 0 1 -

-

Bottom

Bottom

Top

Top