|

|

Control Using This Application |

Self Balancing Robot Using ESP32

Hey👋 guys! Welcome back In this New Project Today We will show you how to make a robot at home. This mini robot is very powerful and easy to make at home. You can make this Diy robot using some Components. Here I am using stepper motor to build this robot.

A self-balancing personal transporter is a single-person electric vehicle comprising a one- or two-wheeled platform on which the rider stands. Unlike other vehicles, it uses a self-balancing gyroscopic system for steering, changing directions depending on which way the rider leans.

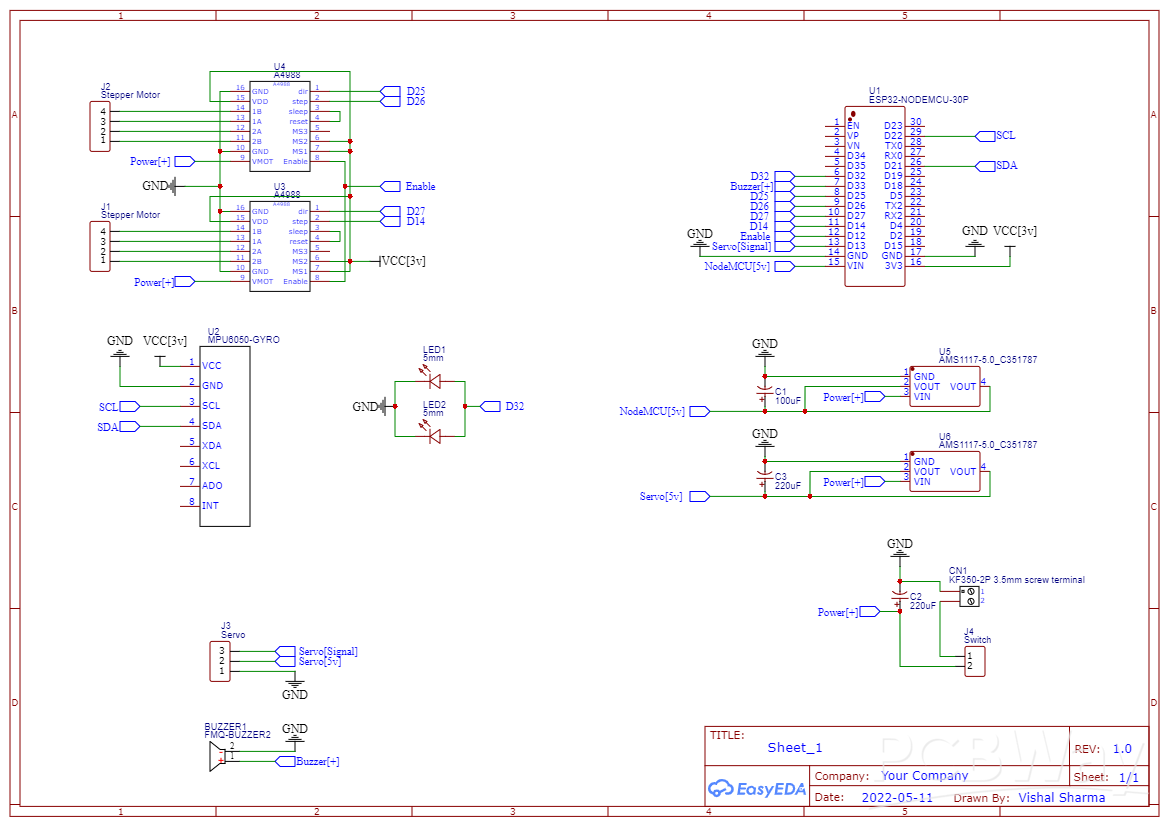

I'll show you how to build a small self-balancing robot that can move around avoiding obstacles. This is a tiny robot measuring 4 inches wide and 4 inches tall and is based on the ESP32 development board and the MPU6050 accelerometer-gyroscope module.

In the steps that follow, we will see how to interface the MPU6050 with Arduino, how to measure the angle of inclination of the robot, how to use PID to make the robot stay balanced. An ultrasonic rangefinder is also added to the robot which prevents it from banging into obstacles as it wanders around.

Speedy detection of errors is possible. Balancing is done quickly and thus saves time, labour and money. The system helps reducing fraud.

The robot will only use a MPU6050 sensor for evaluating and navigating the terrain, a triple axis accelerometer and gyro for calculating angular velocities and accelerations, and Arduino.

In general, a humanoid robot is statically stable if its stability is maintained at any point in time of its movement [1]. Static stability is secured in the condition where the projection of the robot's center of gravity is at all times within the convex polygon defined by the feet that are currently touching the pad.

This Robot is special maked for IoT Project. Because I am a Robotic Software Engineer. I also make awesome Projects For Students & Makers. This is a small part to make a real Robot. Hope You like & Enjoy it.

/*

* esp32_wifi_balancing_robot.ino

*

* Created on: 23.02.2021

* Author: anonymous

*/

#include <Wire.h>

#include <WiFi.h>

#include <ArduinoOTA.h>

#include <Arduino.h>

#include <AsyncTCP.h>

#include <ESPAsyncWebServer.h>

#include "Control.h"

#include "MPU6050.h"

#include "Motors.h"

#include "defines.h"

#include "globals.h"

#include <stdio.h>

#include "esp_types.h"

#include "soc/timer_group_struct.h"

#include "driver/periph_ctrl.h"

#include "driver/timer.h"

#include "driver/ledc.h"

#include "esp32-hal-ledc.h"

const char* PARAM_FADER1 = "fader1";

const char* PARAM_FADER2 = "fader2";

const char* PARAM_PUSH1 = "push1";

const char* PARAM_PUSH2 = "push2";

const char* PARAM_PUSH3 = "push3";

const char* PARAM_PUSH4 = "push4";

const char* PARAM_TOGGLE1 = "toggle1";

const char* PARAM_FADER3 = "fader3";

const char* PARAM_FADER4 = "fader4";

const char* PARAM_FADER5 = "fader5";

const char* PARAM_FADER6 = "fader6";

/* Wifi Crdentials */

String sta_ssid = ""; // set Wifi network you want to connect to

String sta_password = ""; // set password for Wifi network

unsigned long previousMillis = 0;

AsyncWebServer server(80);

void initMPU6050() {

MPU6050_setup();

delay(500);

MPU6050_calibrate();

}

void initTimers();

void notFound(AsyncWebServerRequest *request) {

request->send(404, "text/plain", "Not found");

}

void setup() {

Serial.begin(115200); // set up seriamonitor at 115200 bps

Serial.setDebugOutput(true);

Serial.println();

Serial.println("*ESP32 Wifi Balancing Robot*");

Serial.println("--------------------------------------------------------");

pinMode(PIN_ENABLE_MOTORS, OUTPUT);

digitalWrite(PIN_ENABLE_MOTORS, HIGH);

pinMode(PIN_MOTOR1_DIR, OUTPUT);

pinMode(PIN_MOTOR1_STEP, OUTPUT);

pinMode(PIN_MOTOR2_DIR, OUTPUT);

pinMode(PIN_MOTOR2_STEP, OUTPUT);

pinMode(PIN_SERVO, OUTPUT);

pinMode(PIN_LED, OUTPUT);

digitalWrite(PIN_LED, LOW);

pinMode(PIN_WIFI_LED, OUTPUT);

digitalWrite(PIN_WIFI_LED, LOW);

pinMode(PIN_BUZZER, OUTPUT);

digitalWrite(PIN_BUZZER, LOW);

ledcSetup(6, 50, 16); // channel 6, 50 Hz, 16-bit width

ledcAttachPin(PIN_SERVO, 6); // GPIO 22 assigned to channel 1

delay(50);

ledcWrite(6, SERVO_AUX_NEUTRO);

Wire.begin();

initMPU6050();

// Set NodeMCU Wifi hostname based on chip mac address

char chip_id[15];

snprintf(chip_id, 15, "%04X", (uint16_t)(ESP.getEfuseMac()>>32));

String hostname = "esp32brobot-" + String(chip_id);

Serial.println();

Serial.println("Hostname: "+hostname);

// first, set NodeMCU as STA mode to connect with a Wifi network

WiFi.mode(WIFI_STA);

WiFi.begin(sta_ssid.c_str(), sta_password.c_str());

Serial.println("");

Serial.print("Connecting to: ");

Serial.println(sta_ssid);

Serial.print("Password: ");

Serial.println(sta_password);

// try to connect with Wifi network about 8 seconds

unsigned long currentMillis = millis();

previousMillis = currentMillis;

while (WiFi.status() != WL_CONNECTED && currentMillis - previousMillis <= 8000) {

delay(500);

Serial.print(".");

currentMillis = millis();

}

// if failed to connect with Wifi network set NodeMCU as AP mode

IPAddress myIP;

if (WiFi.status() == WL_CONNECTED) {

Serial.println("");

Serial.println("*WiFi-STA-Mode*");

Serial.print("IP: ");

myIP=WiFi.localIP();

Serial.println(myIP);

digitalWrite(PIN_WIFI_LED, HIGH); // Wifi LED on when connected to Wifi as STA mode

delay(2000);

} else {

WiFi.mode(WIFI_AP);

WiFi.softAP(hostname.c_str());

myIP = WiFi.softAPIP();

Serial.println("");

Serial.println("WiFi failed connected to " + sta_ssid);

Serial.println("");

Serial.println("*WiFi-AP-Mode*");

Serial.print("AP IP address: ");

Serial.println(myIP);

digitalWrite(PIN_WIFI_LED, LOW); // Wifi LED off when status as AP mode

delay(2000);

}

// Send a GET request to <ESP_IP>/?fader=<inputValue>

server.on("/", HTTP_GET, [] (AsyncWebServerRequest *request) {

String inputValue;

String inputMessage;

OSCnewMessage = 1;

// Get value for Forward/Backward

if (request->hasParam(PARAM_FADER1)) {

OSCpage = 1;

inputValue = request->getParam(PARAM_FADER1)->value();

inputMessage = PARAM_FADER1;

OSCfader[0] = inputValue.toFloat();

}

// Get value for Right/Left

else if (request->hasParam(PARAM_FADER2)) {

OSCpage = 1;

inputValue = request->getParam(PARAM_FADER2)->value();

inputMessage = PARAM_FADER2;

OSCfader[1] = inputValue.toFloat();

}

// Get value for Servo0

else if (request->hasParam(PARAM_PUSH1)) {

OSCpage = 1;

inputValue = request->getParam(PARAM_PUSH1)->value();

inputMessage = PARAM_PUSH1;

if(inputValue.equals("1")) OSCpush[0]=1;

else OSCpush[0]=0;

}

// Get value for Setting

else if (request->hasParam(PARAM_PUSH2)) {

OSCpage = 2;

inputValue = request->getParam(PARAM_PUSH2)->value();

inputMessage = PARAM_PUSH2;

if(inputValue.equals("1")) OSCpush[2]=1;

else OSCpush[2]=0;

}

// Get value for Buzzer

else if (request->hasParam(PARAM_PUSH3)) {

inputValue = request->getParam(PARAM_PUSH3)->value();

inputMessage = PARAM_PUSH3;

if(inputValue.equals("1")) {

digitalWrite(PIN_BUZZER, HIGH);

delay(150);

digitalWrite(PIN_BUZZER, LOW);

delay(80);

digitalWrite(PIN_BUZZER, HIGH);

delay(150);

digitalWrite(PIN_BUZZER, LOW);

delay(80);

}

}

// Get value for Led

else if (request->hasParam(PARAM_PUSH4)) {

inputValue = request->getParam(PARAM_PUSH4)->value();

inputMessage = PARAM_PUSH4;

if(inputValue.equals("1")) digitalWrite(PIN_LED, HIGH);

else digitalWrite(PIN_LED, LOW);

}

// Get value for mode PRO

else if (request->hasParam(PARAM_TOGGLE1)) {

OSCpage = 1;

inputValue = request->getParam(PARAM_TOGGLE1)->value();

inputMessage = PARAM_TOGGLE1;

if(inputValue.equals("1")) OSCtoggle[0]=1;

else OSCtoggle[0]=0;

}

// Get value for P-Stability

else if (request->hasParam(PARAM_FADER3)) {

OSCpage = 2;

inputValue = request->getParam(PARAM_FADER3)->value();

inputMessage = PARAM_FADER3;

OSCfader[0] = inputValue.toFloat();

}

// Get value for D-Stability

else if (request->hasParam(PARAM_FADER4)) {

OSCpage = 2;

inputValue = request->getParam(PARAM_FADER4)->value();

inputMessage = PARAM_FADER4;

OSCfader[0] = inputValue.toFloat();

}

// Get value for P-Speed

else if (request->hasParam(PARAM_FADER5)) {

OSCpage = 2;

inputValue = request->getParam(PARAM_FADER5)->value();

inputMessage = PARAM_FADER5;

OSCfader[0] = inputValue.toFloat();

}

// Get value for I-Speed

else if (request->hasParam(PARAM_FADER6)) {

OSCpage = 2;

inputValue = request->getParam(PARAM_FADER6)->value();

inputMessage = PARAM_FADER6;

OSCfader[0] = inputValue.toFloat();

}

else {

inputValue = "No message sent";

}

Serial.println(inputMessage+'='+inputValue);

request->send(200, "text/text", "");

});

server.onNotFound (notFound); // when a client requests an unknown URI (i.e. something other than "/"), call function "handleNotFound"

server.begin(); // actually start the server

initTimers();

// default neutral values

OSCfader[0] = 0.5;

OSCfader[1] = 0.5;

OSCfader[2] = 0.5;

OSCfader[3] = 0.5;

digitalWrite(PIN_ENABLE_MOTORS, LOW);

for (uint8_t k = 0; k < 5; k++) {

setMotorSpeedM1(5);

setMotorSpeedM2(5);

ledcWrite(6, SERVO_AUX_NEUTRO + 250);

delay(200);

setMotorSpeedM1(-5);

setMotorSpeedM2(-5);

ledcWrite(6, SERVO_AUX_NEUTRO - 250);

delay(200);

}

ledcWrite(6, SERVO_AUX_NEUTRO);

ArduinoOTA.begin(); // enable to receive update/upload firmware via Wifi OTA

}

void loop() {

ArduinoOTA.handle();

if (OSCnewMessage) {

OSCnewMessage = 0;

processOSCMsg();

}

timer_value = micros();

if (MPU6050_newData()) {

MPU6050_read_3axis();

dt = (timer_value - timer_old) * 0.000001; // dt in seconds

//Serial.println(timer_value - timer_old);

timer_old = timer_value;

angle_adjusted_Old = angle_adjusted;

// Get new orientation angle from IMU (MPU6050)

float MPU_sensor_angle = MPU6050_getAngle(dt);

angle_adjusted = MPU_sensor_angle + angle_offset;

if ((MPU_sensor_angle > -15) && (MPU_sensor_angle < 15))

angle_adjusted_filtered = angle_adjusted_filtered * 0.99 + MPU_sensor_angle * 0.01;

// We calculate the estimated robot speed:

// Estimated_Speed = angular_velocity_of_stepper_motors(combined) - angular_velocity_of_robot(angle measured by IMU)

actual_robot_speed = (speed_M1 + speed_M2) / 2; // Positive: forward

int16_t angular_velocity = (angle_adjusted - angle_adjusted_Old) * 25.0; // 25 is an empirical extracted factor to adjust for real units

int16_t estimated_speed = -actual_robot_speed + angular_velocity;

estimated_speed_filtered = estimated_speed_filtered * 0.9 + (float) estimated_speed * 0.1; // low pass filter on estimated speed

if (positionControlMode) {

// POSITION CONTROL. INPUT: Target steps for each motor. Output: motors speed

motor1_control = positionPDControl(steps1, target_steps1, Kp_position, Kd_position, speed_M1);

motor2_control = positionPDControl(steps2, target_steps2, Kp_position, Kd_position, speed_M2);

// Convert from motor position control to throttle / steering commands

throttle = (motor1_control + motor2_control) / 2;

throttle = constrain(throttle, -190, 190);

steering = motor2_control - motor1_control;

steering = constrain(steering, -50, 50);

}

// ROBOT SPEED CONTROL: This is a PI controller.

// input:user throttle(robot speed), variable: estimated robot speed, output: target robot angle to get the desired speed

target_angle = speedPIControl(dt, estimated_speed_filtered, throttle, Kp_thr, Ki_thr);

target_angle = constrain(target_angle, -max_target_angle, max_target_angle); // limited output

// Stability control (100Hz loop): This is a PD controller.

// input: robot target angle(from SPEED CONTROL), variable: robot angle, output: Motor speed

// We integrate the output (sumatory), so the output is really the motor acceleration, not motor speed.

control_output += stabilityPDControl(dt, angle_adjusted, target_angle, Kp, Kd);

control_output = constrain(control_output, -MAX_CONTROL_OUTPUT, MAX_CONTROL_OUTPUT); // Limit max output from control

// The steering part from the user is injected directly to the output

motor1 = control_output + steering;

motor2 = control_output - steering;

// Limit max speed (control output)

motor1 = constrain(motor1, -MAX_CONTROL_OUTPUT, MAX_CONTROL_OUTPUT);

motor2 = constrain(motor2, -MAX_CONTROL_OUTPUT, MAX_CONTROL_OUTPUT);

int angle_ready;

if (OSCpush[0]) // If we press the SERVO button we start to move

angle_ready = 82;

else

angle_ready = 74; // Default angle

if ((angle_adjusted < angle_ready) && (angle_adjusted > -angle_ready)) // Is robot ready (upright?)

{

// NORMAL MODE

digitalWrite(PIN_ENABLE_MOTORS, LOW); // Motors enable

// NOW we send the commands to the motors

setMotorSpeedM1(motor1);

setMotorSpeedM2(motor2);

} else // Robot not ready (flat), angle > angle_ready => ROBOT OFF

{

digitalWrite(PIN_ENABLE_MOTORS, HIGH); // Disable motors

setMotorSpeedM1(0);

setMotorSpeedM2(0);

PID_errorSum = 0; // Reset PID I term

Kp = KP_RAISEUP; // CONTROL GAINS FOR RAISE UP

Kd = KD_RAISEUP;

Kp_thr = KP_THROTTLE_RAISEUP;

Ki_thr = KI_THROTTLE_RAISEUP;

// RESET steps

steps1 = 0;

steps2 = 0;

positionControlMode = false;

OSCmove_mode = false;

throttle = 0;

steering = 0;

}

// Push1 Move servo arm

if (OSCpush[0]) {

if (angle_adjusted > -40)

ledcWrite(6, SERVO_MAX_PULSEWIDTH);

else

ledcWrite(6, SERVO_MIN_PULSEWIDTH);

} else

ledcWrite(6, SERVO_AUX_NEUTRO);

// Servo2

//ledcWrite(6, SERVO2_NEUTRO + (OSCfader[2] - 0.5) * SERVO2_RANGE);

// Normal condition?

if ((angle_adjusted < 56) && (angle_adjusted > -56)) {

Kp = Kp_user; // Default user control gains

Kd = Kd_user;

Kp_thr = Kp_thr_user;

Ki_thr = Ki_thr_user;

} else // We are in the raise up procedure => we use special control parameters

{

Kp = KP_RAISEUP; // CONTROL GAINS FOR RAISE UP

Kd = KD_RAISEUP;

Kp_thr = KP_THROTTLE_RAISEUP;

Ki_thr = KI_THROTTLE_RAISEUP;

}

} // End of new IMU data

}

void processOSCMsg() {

if (OSCpage == 1) {

if (modifing_control_parameters) // We came from the settings screen

{

OSCfader[0] = 0.5; // default neutral values

OSCfader[1] = 0.5; // default neutral values

OSCtoggle[0] = 0; // Normal mode

mode = 0;

modifing_control_parameters = false;

}

if (OSCmove_mode) {

Serial.print("M ");

Serial.print(OSCmove_speed);

Serial.print(" ");

Serial.print(OSCmove_steps1);

Serial.print(",");

Serial.println(OSCmove_steps2);

positionControlMode = true;

OSCmove_mode = false;

target_steps1 = steps1 + OSCmove_steps1;

target_steps2 = steps2 + OSCmove_steps2;

} else {

positionControlMode = false;

throttle = (OSCfader[0] - 0.5) * max_throttle;

// We add some exponential on steering to smooth the center band

steering = OSCfader[1] - 0.5;

if (steering > 0)

steering = (steering * steering + 0.5 * steering) * max_steering;

else

steering = (-steering * steering + 0.5 * steering) * max_steering;

}

if ((mode == 0) && (OSCtoggle[0])) {

// Change to PRO mode

max_throttle = MAX_THROTTLE_PRO;

max_steering = MAX_STEERING_PRO;

max_target_angle = MAX_TARGET_ANGLE_PRO;

mode = 1;

}

if ((mode == 1) && (OSCtoggle[0] == 0)) {

// Change to NORMAL mode

max_throttle = MAX_THROTTLE;

max_steering = MAX_STEERING;

max_target_angle = MAX_TARGET_ANGLE;

mode = 0;

}

} else if (OSCpage == 2) { // OSC page 2

if (!modifing_control_parameters) {

for (uint8_t i = 0; i < 4; i++)

OSCfader[i] = 0.5;

OSCtoggle[0] = 0;

modifing_control_parameters = true;

//OSC_MsgSend("$P2", 4);

}

// User could adjust KP, KD, KP_THROTTLE and KI_THROTTLE (fadder3,4,5,6)

// Now we need to adjust all the parameters all the times because we dont know what parameter has been moved

Kp_user = KP * 2 * OSCfader[0];

Kd_user = KD * 2 * OSCfader[1];

Kp_thr_user = KP_THROTTLE * 2 * OSCfader[2];

Ki_thr_user = KI_THROTTLE * 2 * OSCfader[3];

// Send a special telemetry message with the new parameters

char auxS[50];

sprintf(auxS, "$tP,%d,%d,%d,%d", int(Kp_user * 1000), int(Kd_user * 1000), int(Kp_thr_user * 1000), int(Ki_thr_user * 1000));

//OSC_MsgSend(auxS, 50);

// Calibration mode??

if (OSCpush[2] == 1) {

Serial.print("Calibration MODE ");

angle_offset = angle_adjusted_filtered;

Serial.println(angle_offset);

}

// Kill robot => Sleep

while (OSCtoggle[0] == 1) {

//Reset external parameters

PID_errorSum = 0;

timer_old = millis();

setMotorSpeedM1(0);

setMotorSpeedM2(0);

digitalWrite(PIN_ENABLE_MOTORS, HIGH); // Disable motors

}

}

}

Self Balancing Robot Using ESP32

*PCBWay community is a sharing platform. We are not responsible for any design issues and parameter issues (board thickness, surface finish, etc.) you choose.

- Comments(2)

- Likes(6)

-

Frank Enbeans

Dec 02,2024

Frank Enbeans

Dec 02,2024

-

Engineer

Sep 05,2024

Engineer

Sep 05,2024

-

Engineer

May 15,2024

Engineer

May 15,2024

-

Im' Peer

Dec 16,2023

Im' Peer

Dec 16,2023

-

Engineer

Sep 17,2023

Engineer

Sep 17,2023

-

The Spanner

Sep 15,2023

The Spanner

Sep 15,2023

- 3 USER VOTES

- YOUR VOTE 0.00 0.00

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

9design

-

7usability

-

8creativity

-

5content

-

9design

-

7usability

-

8creativity

-

6content

-

10design

-

10usability

-

10creativity

-

10content

More by The Spanner

More by The Spanner

-

200w Mini Inverter

Why I build a Mini Inverter at Home?It was night time, I was reading my course subjects for the prep...

200w Mini Inverter

Why I build a Mini Inverter at Home?It was night time, I was reading my course subjects for the prep...

-

DIY 4s Battery Pack on PCB

A DIY 4s Battery Pack is specially maked for Makers & Hobbyist. Inbuilt 4s Smart BMS & XT30 ...

DIY 4s Battery Pack on PCB

A DIY 4s Battery Pack is specially maked for Makers & Hobbyist. Inbuilt 4s Smart BMS & XT30 ...

-

Self Balancing Robot Using ESP32

Hey guys! Welcome back In this New Project Today We will show you how to make a robot at home. This ...

Self Balancing Robot Using ESP32

Hey guys! Welcome back In this New Project Today We will show you how to make a robot at home. This ...

-

-

AEL-2011 Power Supply Module

524 0 2 -

AEL-2011 50W Power Amplifier

485 0 2 -

-

-

Custom Mechanical Keyboard

693 0 0 -

Tester for Touch Screen Digitizer without using microcontroller

329 2 2 -

Audio reactive glow LED wristband/bracelet with NFC / RFID-Tags

310 0 1 -

-

-