Stanley A Meyer 9 Cell WFC top Cap original

Stanley A Meyer 9 Cell WFC top Cap original

JOIN US HERE

LEARN EVERYTHING BE A GLOBAL MASTER WITH US

NANO BUBBLEWATER FUEL

https://www.patreon.com/c/securesupplies/shop

The Stanley A. Meyer 9-Cell WFC Top Cap was an essential component in his water fuel cell (WFC) design, especially for controlling the flow of the produced hydrogen and oxygen gases, as well as managing pressure within the cell. Meyer’s innovative approach allowed this top cap to serve multiple functions, from gas collection and delivery to pressure regulation. Here’s how the top cap worked and its significance in producing and extracting nano-bubble hydrogen fuel.

Functions of the Stanley A. Meyer 9-Cell WFC Top Cap

Gas Collection and Flow Control:

The top cap on the 9-cell WFC was designed to collect the nano-bubble hydrogen and oxygen gases produced within the water cell. Since the gases would rise naturally to the top, the cap acted as a primary collection point, channeling the gases for controlled extraction.

The cap typically had one or more ports that could be connected to tubing, allowing the gases to flow out in a controlled manner. This design enabled Meyer to route the gas directly to the engine’s intake system or storage tanks as a fuel source.

Pressure Regulation:

The top cap played a critical role in maintaining and regulating internal pressure within the WFC. In Meyer’s design, maintaining optimal pressure within the cell was essential for efficient gas production, as too high or low a pressure could disrupt the cell’s operation.

Meyer likely integrated a pressure relief valve or similar mechanism into the top cap, allowing excess gas pressure to escape safely to avoid over-pressurization. This feature was particularly important for automotive applications, where pressure spikes could occur due to variable demand and the dynamic environment of a moving vehicle.

Safety Control with Flashback Prevention:

The cap’s design also included measures for preventing flashbacks, a potentially dangerous situation where ignited gas could flow back into the cell and cause an explosion. Meyer incorporated flashback arrestors or check valves within or attached to the top cap to prevent any flame from entering the WFC.

These components would allow gas to flow out of the cell but would automatically block any reverse flow, thereby enhancing safety for both the vehicle and the cell’s longevity.

Monitoring with Pressure Gauges:

Meyer’s top cap design typically included ports or fittings for attaching pressure gauges. By using a pressure gauge, Meyer could monitor the internal pressure of the cell in real-time, providing valuable information about gas production rates and ensuring the system was operating within safe pressure limits.

Pressure monitoring also allowed Meyer to adjust the system’s settings for different driving conditions or engine demands. For instance, he could increase or decrease the rate of gas production depending on whether the vehicle was idling, accelerating, or under heavy load.

Versatile Gas Output for Fuel Delivery:

The top cap was designed with multiple connection points or adapter options for versatility in gas delivery. Meyer could connect the output to different destinations, such as the vehicle’s intake manifold or a carburetor, allowing the gases to serve directly as a combustible fuel.

The design also allowed for controlled release of nano-bubble hydrogen. When nano-bubbles were formed within the cell, the top cap allowed Meyer to channel this highly reactive fuel directly into the engine intake, enhancing combustion efficiency. Nano-bubbles offer a larger surface area, making the hydrogen more combustible and creating a more efficient fuel source for the engine.

Extraction of Hydrogen for Alternative Uses:

Meyer’s system also provided flexibility for situations where he might want to use the produced gas outside of the direct fuel-injection method. For example, he could channel the hydrogen to a storage tank or other fuel cell systems.

The top cap allowed for easy integration with external piping and fittings, facilitating gas extraction through specific valves or tubing. This versatility was especially useful if Meyer wanted to extract the hydrogen for alternative applications or experimentation, including the potential extraction of nano-bubble-infused water.

Design Elements of the 9-Cell WFC Top Cap

Material and Construction: The cap was usually made of durable, non-corrosive materials like stainless steel or high-grade plastic. These materials resisted the effects of water and hydrogen exposure, providing longevity and minimizing maintenance.

Port Configurations: The cap featured various ports and threaded connections to accommodate different fittings for gas lines, pressure gauges, and valves. This allowed the cell to be easily connected to an engine intake or gas storage system as needed.

Flashback Arrestors/Check Valves: To ensure safety, the top cap included flashback arrestors or check valves that prevented the gas from igniting back into the WFC. These safety components were crucial in reducing the risk of explosion in a pressurized hydrogen system.

Pressure Relief Valve: Meyer’s top cap design also featured a pressure relief valve to protect the cell from over-pressurization, which could damage the WFC or lead to dangerous pressure buildup. The relief valve would automatically vent excess gas if the internal pressure exceeded a preset limit.

Application in a High-Performance Environment (e.g., Hydrogen-Powered Hot Rod)

In a hydrogen-powered vehicle like a hot rod, the top cap design was essential for handling the high flow rates and pressures required for high-performance applications. The ability to precisely control gas flow, prevent flashback, and regulate pressure was crucial for delivering a reliable, on-demand hydrogen fuel supply. This ensured the WFC could sustain continuous, efficient gas production even under varying demands such as rapid acceleration or steep inclines.

Summary

The Stanley A. Meyer 9-Cell WFC Top Cap was a critical component that ensured the safe, efficient extraction and delivery of hydrogen and oxygen gases from the water fuel cell.

Through features like pressure regulation, flashback prevention, and adaptable gas output ports, Meyer’s top cap design provided the necessary flexibility and safety for automotive applications. By managing the outflow of gases and maintaining optimal internal pressure, the top cap allowed Meyer’s WFC to function as a reliable, high-performance fuel source, advancing his vision for a hydrogen-powered vehicle.

Stanley A Meyer 9 Cell WFC top Cap original

*PCBWay community is a sharing platform. We are not responsible for any design issues and parameter issues (board thickness, surface finish, etc.) you choose.

- Comments(0)

- Likes(1)

-

Daniel Donatelli

Nov 08,2024

Daniel Donatelli

Nov 08,2024

- 0 USER VOTES

- YOUR VOTE 0.00 0.00

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

More by Daniel Donatelli

More by Daniel Donatelli

-

Stanley A Meyer VIC Voltage intensifier circuit transformer board v1.8 updated jan 11 2021

Stanley A Meyer VIC Voltage intensifier transformer board Join Support help change the World https:/...

Stanley A Meyer VIC Voltage intensifier circuit transformer board v1.8 updated jan 11 2021

Stanley A Meyer VIC Voltage intensifier transformer board Join Support help change the World https:/...

-

STANLEY A MEYER LES BANKI AUTO START AUTO WATER FUEL REFILL

STANLEY A MEYER LES BANKI AUTO START AUTO WATER FUEL REFILLJoin Support help change the World https:...

STANLEY A MEYER LES BANKI AUTO START AUTO WATER FUEL REFILL

STANLEY A MEYER LES BANKI AUTO START AUTO WATER FUEL REFILLJoin Support help change the World https:...

-

Stanley A Meyer Gated Pulse Frequency Generator K3 with DB 37 updated 060622

Stanley A Meyer Gated Pulse Frequency Generator K3 with DB 37 to suit matrix vic main board Join Sup...

Stanley A Meyer Gated Pulse Frequency Generator K3 with DB 37 updated 060622

Stanley A Meyer Gated Pulse Frequency Generator K3 with DB 37 to suit matrix vic main board Join Sup...

-

Stanley A Meyer K2 Variable Pulse Frequency Generator GMS Vic Matrix PCB Gerber

Stanley A Meyer K2 Variable Pulse Frequency Generator GMS Vic Matrix PCBGerberJoin Support help chan...

Stanley A Meyer K2 Variable Pulse Frequency Generator GMS Vic Matrix PCB Gerber

Stanley A Meyer K2 Variable Pulse Frequency Generator GMS Vic Matrix PCBGerberJoin Support help chan...

-

Hyduino Stim Stimulator circuit board Ms EMS ECU

Hyduino Stim Stimulator circuit board Ms EMS ECUJoin Support help change the World https://www.patre...

Hyduino Stim Stimulator circuit board Ms EMS ECU

Hyduino Stim Stimulator circuit board Ms EMS ECUJoin Support help change the World https://www.patre...

-

Stanley A Meyer VIC Daughter Board Driver Transistor Circuit board Version 1

Stanley A Meyer VIC Daughter Board Driver Transistor Circuit board Version 1 Updated 28th Sept 2021 ...

Stanley A Meyer VIC Daughter Board Driver Transistor Circuit board Version 1

Stanley A Meyer VIC Daughter Board Driver Transistor Circuit board Version 1 Updated 28th Sept 2021 ...

-

Stanley A Meyer VIC Daughter Board Driver USed with Variac EEC eleectron eextrract & chokes

Stanley A Meyer VIC Daughter Board Driver USed with Variac EEC eleectron extrract & chokes can d...

Stanley A Meyer VIC Daughter Board Driver USed with Variac EEC eleectron eextrract & chokes

Stanley A Meyer VIC Daughter Board Driver USed with Variac EEC eleectron extrract & chokes can d...

-

Stanley A Meyer Fuel Line Insert WFC Nano Bubble Water Fuel Cell V3

Stanley A Meyer WFC Nano Bubble Water Fuel Cell V3 Barbed Fuel Line insert Stanley a Meyer WFC Nano ...

Stanley A Meyer Fuel Line Insert WFC Nano Bubble Water Fuel Cell V3

Stanley A Meyer WFC Nano Bubble Water Fuel Cell V3 Barbed Fuel Line insert Stanley a Meyer WFC Nano ...

-

Stanley A Meyer Nano Bubble Water Fuel Cell WFC Parts 2026 V2

Stanley a Meyer WFC Nano Bubble Water Fuel Cell Single Cell 2026Stanley a Meyer Single Cell 2026This...

Stanley A Meyer Nano Bubble Water Fuel Cell WFC Parts 2026 V2

Stanley a Meyer WFC Nano Bubble Water Fuel Cell Single Cell 2026Stanley a Meyer Single Cell 2026This...

-

Stanley a Meyer WFC Nano Bubble Water Fuel Cell Single Cell 2026

Stanley a Meyer Single Cell 2026This is a work to make it faster easier for every one to get the cel...

Stanley a Meyer WFC Nano Bubble Water Fuel Cell Single Cell 2026

Stanley a Meyer Single Cell 2026This is a work to make it faster easier for every one to get the cel...

-

2025 Stanley A Meyer Egan Half Bridge Switch VOLTROLYSIS

2025 Stanley A Meyer Egan Half Bridge Switch VOLTROLYSISJoin the Builder LevelBy joining the Builder...

2025 Stanley A Meyer Egan Half Bridge Switch VOLTROLYSIS

2025 Stanley A Meyer Egan Half Bridge Switch VOLTROLYSISJoin the Builder LevelBy joining the Builder...

-

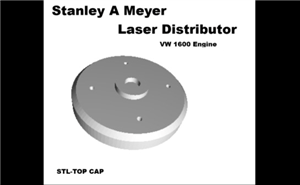

Stanley A Meyer vw 1600 Cap Laser Distributor

Stanley A Meyer vw 1600 Cap Laser DistributorVideo https://youtu.be/XQd8zwEA4LE?si=dpG4jgLsHhYTkX5cJ...

Stanley A Meyer vw 1600 Cap Laser Distributor

Stanley A Meyer vw 1600 Cap Laser DistributorVideo https://youtu.be/XQd8zwEA4LE?si=dpG4jgLsHhYTkX5cJ...

-

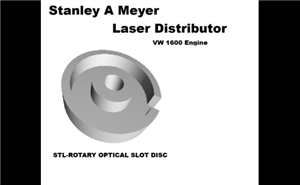

Stanley A Meyer vw 1600 STL-ROTARY OPTICAL SLOT DISC

Stanley A Meyer vw 1600 STL-ROTARY OPTICAL SLOT DISCVideo https://youtu.be/XQd8zwEA4LE?si=dpG4jgLsHh...

Stanley A Meyer vw 1600 STL-ROTARY OPTICAL SLOT DISC

Stanley A Meyer vw 1600 STL-ROTARY OPTICAL SLOT DISCVideo https://youtu.be/XQd8zwEA4LE?si=dpG4jgLsHh...

-

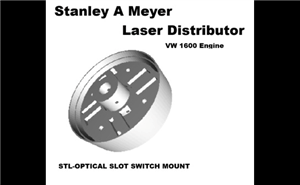

Stanley A Meyer vw 1600 STL-OPTICAL SLOT SWITCH MOUNT

Stanley A Meyer vw 1600 STL-OPTICAL SLOT SWITCH MOUNTVideo https://youtu.be/XQd8zwEA4LE?si=dpG4jgLsH...

Stanley A Meyer vw 1600 STL-OPTICAL SLOT SWITCH MOUNT

Stanley A Meyer vw 1600 STL-OPTICAL SLOT SWITCH MOUNTVideo https://youtu.be/XQd8zwEA4LE?si=dpG4jgLsH...

-

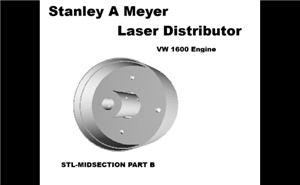

Stanley Meyer Laser VW 1600 Buggy Distributor STL-MIDSECTION PART B

Stanley Meyer Laser VW 1600 Buggy Distributor STL-MIDSECTION PART BVideo https://youtu.be/XQd8zwEA4L...

Stanley Meyer Laser VW 1600 Buggy Distributor STL-MIDSECTION PART B

Stanley Meyer Laser VW 1600 Buggy Distributor STL-MIDSECTION PART BVideo https://youtu.be/XQd8zwEA4L...

-

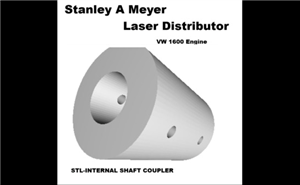

Stanley Meyer Laser VW 1600 Buggy Distributor STL-INTERNAL SHAFT COUPLER

Stanley Meyer Laser VW 1600 Buggy Distributor STL-INTERNAL SHAFT COUPLER Video https://youtu.be/XQd8...

Stanley Meyer Laser VW 1600 Buggy Distributor STL-INTERNAL SHAFT COUPLER

Stanley Meyer Laser VW 1600 Buggy Distributor STL-INTERNAL SHAFT COUPLER Video https://youtu.be/XQd8...

-

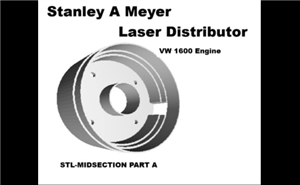

Stanley Meyer Laser VW 1600 Buggy Distributor STL-MIDSECTION PART A

Stanley Meyer Laser VW 1600 Buggy STL-MIDSECTION PART A Video https://youtu.be/XQd8zwEA4LE?si=dpG4jg...

Stanley Meyer Laser VW 1600 Buggy Distributor STL-MIDSECTION PART A

Stanley Meyer Laser VW 1600 Buggy STL-MIDSECTION PART A Video https://youtu.be/XQd8zwEA4LE?si=dpG4jg...

-

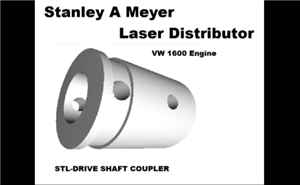

Stanley Meyer Laser VW 1600 Buggy Distributor STL-DRIVE SHAFT COUPLER (1)

Stanley Meyer Laser VW 1600 Buggy Distributor Video https://youtu.be/XQd8zwEA4LE?si=dpG4jgLsHhYTkX5c...

Stanley Meyer Laser VW 1600 Buggy Distributor STL-DRIVE SHAFT COUPLER (1)

Stanley Meyer Laser VW 1600 Buggy Distributor Video https://youtu.be/XQd8zwEA4LE?si=dpG4jgLsHhYTkX5c...

-

-

mammoth-3D SLM Voron Toolhead – Manual Drill & Tap Edition

252 0 0 -

-

AEL-2011 Power Supply Module

779 0 2 -

AEL-2011 50W Power Amplifier

646 0 2 -

-

-

Custom Mechanical Keyboard

839 0 0 -

Tester for Touch Screen Digitizer without using microcontroller

462 2 2 -

Audio reactive glow LED wristband/bracelet with NFC / RFID-Tags

407 0 1 -

-