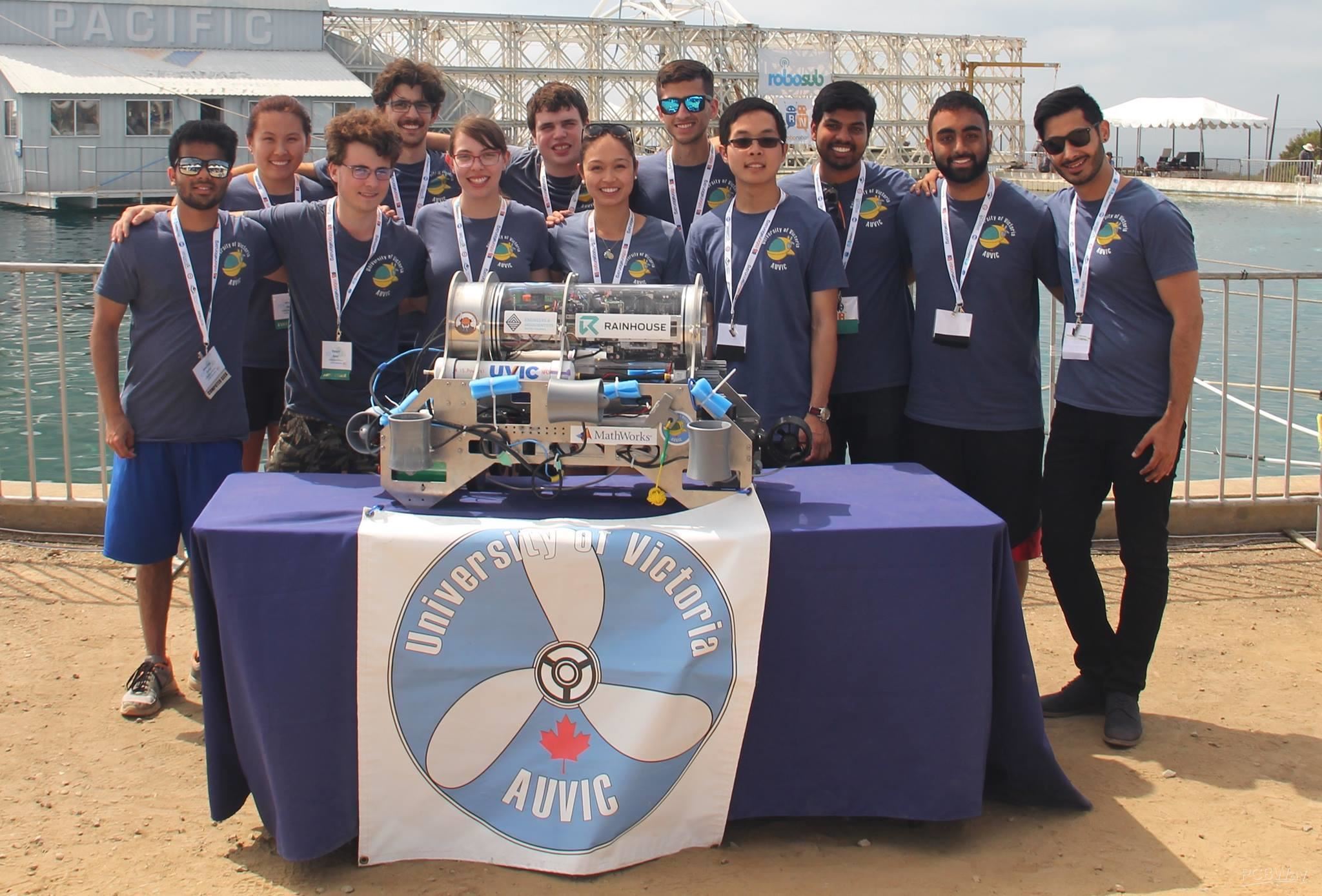

AUVIC's Polaris (2019

About Us

AUVIC is an interdisciplinary engineering team at the the University of Victoria (UVic) in Victoria, BC, Canada that works to design and create an autonomous underwater vehicle (AUV). The team is currently composed of three engineering teams, (electrical, mechanical, and software), that work together in preparing and building the AUV for the annual RoboSub competition in San Diego, California. The primary goal of AUVIC is to provide members with hands-on experience with autonomous technology, embedded systems, and mechanical design in an underwater environment. Its secondary goal is to advance the knowledge and development of AUVs and to be one of the top competitors in the RoboSub competition.

Electrical Team

AUVIC's electrical team has approximately 7 members, lots of which are in the first couple years of study. Most of the students on the electrical team joined within the last year or two. There are many bright members in the club, all of whom are passionate about electronics, and are eager to learn, and try out their new ideas.

RoboSub

The RoboSub competition is an international competition designed to challenge students around the world to design and build a fully-autonomous submarine to complete various obstacles without any human intervention. The submarine must make use of computer vision for identifying targets, sonar systems to identify and locate underwater speakers, as well as various other peripherals to complete tasks of various complexities. The competition provides an excellent opportunity to network with bright minds around the world, and provides an excellent learning environment for the many students who compete at it.

Polaris (2019)

AUVIC's 2019 submarine, Polaris, is currently undergoing revisions from last year. The frame makes the submarine more accessible, miniature torpedoes have been added to complete more events at competition, and a large portion of the electrical systems have been redesigned. The submarine is currently in the revisions phase, with attention paid most to Power board, torpedos, and hydrophone Pre-amp. The submarine will have eight motors, two torpedoes, an array of four hydrophones, a system for acquiring payloads underwater, a system for dispensing the acquired payloads, and a method for pulling/pushing levers while underwater.

3D Rendering of Polaris, the 2018 Submarine

Of the electrical system, it comprises of a power regulation board, a motor controller board, hydrophones to sense sound waves coming from underwater pingers, battery monitor circuits, boards for controlling the payload acquisition systems, as well as triggering the torpedoes.

Circuit Boards

The majority of the boards we use for the submarine are custom PCBs. We use STM32 microcontrollers, and our prototyping is done using STM32 development boards. Our custom PCB's have these microcontrollers onboard, along with all the external peripherals. All our PCB's are designed using Altium.

Power Regulation Board (Rev 2)

The Power Regulation Board is the central power hub for all components on the submarine. The board selects either the batteries or a tethered power source to power the sub, and is capable of cutting power via an onboard microcontroller to various systems in the submarine. RoboSub requires that the sub have a kill switch with can be pulled by divers to cut power to the submarine. This is implemented by using a magnetic switch, which cuts power to the sub when the switch is pulled. The board must also be able to handle enough current to power the eight motors. The board also acts as a monitor for the main housing of the submarine. It monitors internal housing pressure, temperature and humidity. It comes with an onboard water sensor, and it has the capabilities to measure the external water pressure, outside the housing. It measures the current draw on both the batteries, and individual subsystems, and has the ability to connect and disconnect the batteries in parallel using control logic from the microcontroller. The board is fused to protect against shorts in any of the subsystems.

Power Regulation Board 3D Rendering (Top Layer)

The board has a USB connector that can be used for USART communications. The microcontroller also has the capabilities to be powered either through USB or by the batteries, which is useful for debugging purposes, when batteries aren't available. The relays are used to switch between battery power and tether power, and will always chose tether power over battery power when the tether is available. This can be used to easily conserve battery life.

Hydrophones

Sonar systems are an integral part of the submarine design. To complete many of the objectives in the competitions, the submarine must be able to locate pingers, or underwater speakers, emitting sound at fixed frequencies. The solve this problem, our submarine has an array of four hydrophones (underwater microphones). These hydrophones are all separated by a fixed/known distance. By analyzing the phase difference of the incoming waves to the array of hydrophones, we can triangulate the location of the pinger. To accomplish this all of this, the hydrophone boards process and convert the incoming data.

The hydrophone boards consist of two sub-boards: the microcontroller board and the pre-amplification board. The pre-amplification board is placed at the same location as the hydrophones, in a small housing at the bottom of the submarine. The board amplifies all incoming signals from the hydrophones, and transmits them off to the main housing. In the main housing, the microcontroller board converts the analog signals to digital, and sends the digital data to the main computer.

Pre-Amplification Hydrophone Board Top Layer

Microcontroller Hydrophone Board Top Layer

Motor Controller

The submarine has 8 motor, each of which must be controlled using a PWM signal to an ECS. The motor controller uses a microcontroller with a Cortex-M4 microprocessor, allowing for more complex computations, which could be used for any necessary control systems, such as PID. It is situated in its own housing, controlling all eight motors from the single board. It takes in commands from the main computer via UART, and has the capability of reading back the motor RPM by filtering the output of a motor pole.

Motor Controller Board Top Layer

All three boards have been built, however faults have been found in each board. Most notably, the power regulation board had missing traces. We have designed and prepared a new revision for the power board and as well as the hydrophone pre-amp.

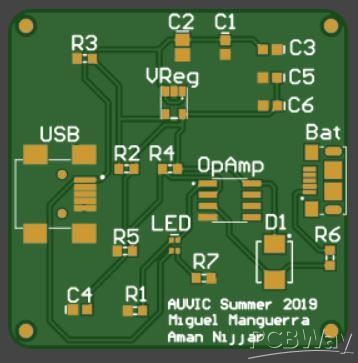

Miscellaneous Boards

Our team is always thinking of cool ideas for new boards, and this year, we are going to be making boards to replicate the competition pinger and a battery charger.. This is to introduce new members into the team.

Underwater Acoustic Transmitter (Pinger)

This project was to create a 25-40 kHZ pulse to enable testing Polaris's controls and hydrophones. More info can be found on the project page: https://www.pcbway.com/project/shareproject/Acoustic_Underwater_Transmitter.html

Nickel Cadmium Battery Charger

To charge the battery to power the Pinger. See info here: https://www.pcbway.com/project/shareproject/Ni_Cd_Battery_Charger.html

Ni-Cd Battery Charger

Concluding Remarks

We are students who really enjoy designing electronics and, unfortunately, we don’t have enough money to attempt all the projects we would like for all of our members. Sponsorship from PCBWay would allow us to build and test more of our ideas, and would allow more members in our club to learn about electronics.

For more information, please visit auvic.ca!

- Comments(0)

- Likes(1)