Griffith Racing Team EV23

Our Website:

https://www.griffithracingteam.com/

About Our Team:

Griffith Racing Team competes in a global engineering competition: Formula Student/ FSAE, representing Griffith University. The team is composed of dedicated students who each year, design and manufacture an open wheel race car from the ground up. At the end of each year, the team enters the FSAE – Australasia competition, which hosts the top universities from Australasia.

The competition comprises of events that showcase the team/s engineering design, business and marketing strategies as well as financial management. The competition also focuses on pushing the student to develop vehicles to their absolute limits on the track in a variety of dynamic events. The team has progressed in leaps and bounds since its inception in 2014. These achievements range from 3 rd overall at the 2019 FSAE-A competition to countless University rewards.

Team Update:

2022 saw GRTs first competition since 2019 with our first generation electric vehicle “Shelby”. Now looking to the future, our second-generation electric vehicle GRT is going to feature our first ever carbon fiber monocoque chassis with significant development into our aerodynamic package. 2023 will see a refined and consolidated vehicle with significant increases in vehicle performance which will be showcased in December at Winton Raceway for FSAE-A 2023 competition

Our Goals With PCBWAY:

As we further develop our EV concept for the 2023 competition the design of our electrical systems had begun to increase in functionality and quality. To meet our increasing demands for accuracy and quality we require a PCB manufacture that shares our vison and goals for the future. For our 2023 EV there are both high and low voltage systems that need to all work together for the vehicle to operate successfully.

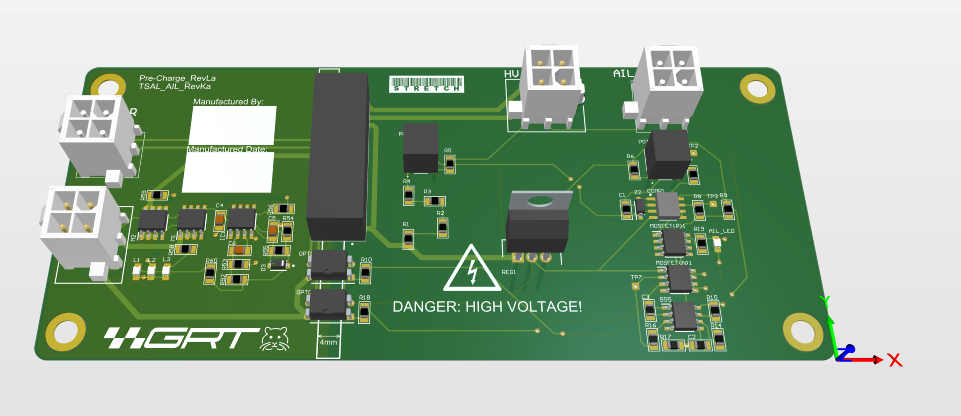

Below is our PCB designed to handle the multiple tasks involving our 400V battery pack such as; pre-charging our motor controller, controlling the tractive system active light on our roll hoop and the tractive system active light on the casing of our battery pack.

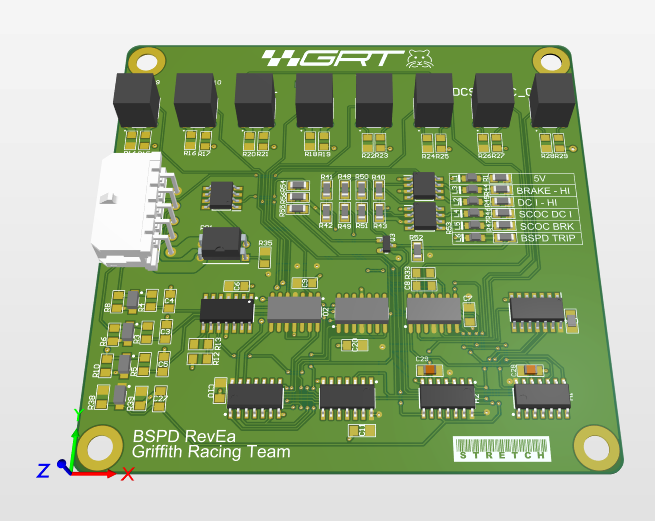

The brake system plausibility device or BSPD is responsible for safely shutting down the tractive system in the event of hard braking and an excess of 5kw of power being drawn from our battery pack.

BSPD PCB design:

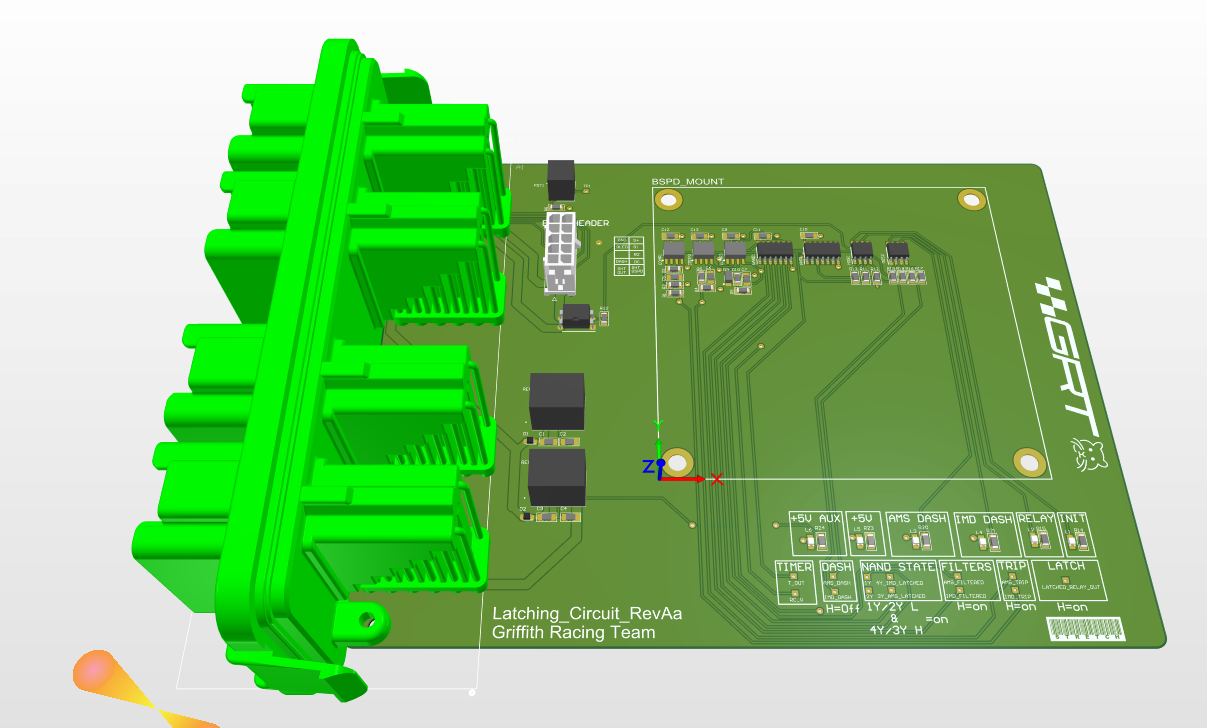

The latching circuit handles input signals from the insulation monitoring device and our battery management system and latches the tractive system off to ensure the safety of the driver. This PCB also doubles for distributing power to the various electrical components on the car and mounting the BSPD circuit.

Latching circuit PCB:

- Comments(0)

- Likes(0)