War Eagle Motorsports - Auburn University

About Us

War Eagle Motorsports is Auburn University’s student-led Formula SAE racing team. The team was founded in 1995 and designs, manufactures, and competes with a new car every year. In 2016 our team placed 1st overall in the U.S. based Lincoln, Nebraska competition, and we are consistently finishing in the top tier of Formula SAE competitions.

In 2021, we will be taking our first electric formula car to competition. As electric cars become more popular in the consumer world, their popularity increases in the racing world. This prompted our team to shift our focus to purely creating an electric car and ensure our young engineers are putting their experience towards sustainable engineering. The car will feature a 600 VDC, 6.29 kWh system making up to 80 kW at any time.

Electric Formula SAE Car

Our team provides an excellent opportunity for students to take an idea and carry it throughout the entire engineering process that many other organizations at our university are unable to offer. We manufacture roughly 85% of parts in our machine shop, which gives team members ample opportunity to learn and develop technical skills outside the classroom.

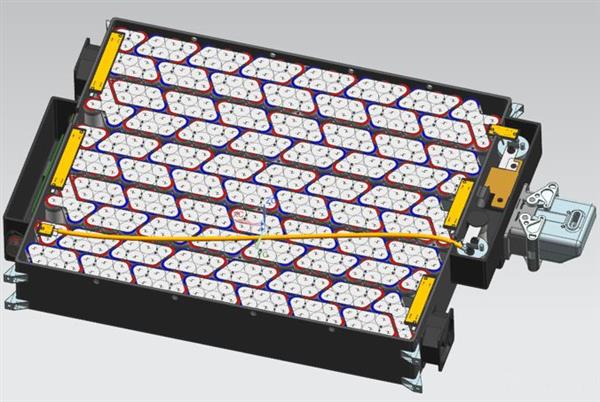

Our powertrain features two synchronous motors for a rear-wheel drive system, allowing the implementation of regenerative braking and torque vectoring. The powertrain is powered by our accumulator which consists of 435 lithium ion cells contained in parallel packs of 3 cells which totals around 594.4 VDC housed in a custom carbon fiber container.

Our formula car features a full carbon fiber monocoque, which we lay up and create in our shop. This has a large impact on the performance of our car, as weight and size are some of the biggest factors in our Formula SAE competitions. The 2021 electric car will weigh in below 365 lbs, making it one of the lightest cars at US competitions.

The Circuit Boards

As we mentioned earlier, weight and size is one of the largest factors in the success of our formula car. This drove us to create a custom battery management system for our accumulator this year in order to reduce its package size and weight. Our design includes custom boards and selecting individual components to meet this requirement.

Slave Boards

The slave boards make up the bulk of our battery management system. There are 5 slave boards in our accumulator which sit on 5 segments of batteries. The slave boards are responsible for monitoring the voltage, current, and temperature of the battery packs as well as actively balancing the packs for more efficient charging and discharging.

Precharge/Discharge Boards

The precharge and discharge boards are both contained within our accumulator case. The precharge board serves as an intermediate board, which charges our motor controllers to 90% of the total accumulator voltage before connecting the motor controllers directly to our accumulator voltage. The discharge board is used to discharge the voltage from our motor controllers after a shutdown event.

Accumulator Indicator Board

The accumulator indicator board, AIC, is used to trigger an LED indicator light in the accumulator once it receives a voltage higher than 60 VDC. This serves as a safety feature, so that anyone working around the accumulator is aware of its current voltage condition.

The 2021 car is an ambitious project and we need the support of PCBWay in order to maximize the educational benefits for team members. The slave boards are the biggest hurdle we have for this year due to their size and complexity. With your support, our manufacturing time would decrease dramatically and it would let us devote more time towards testing and development. This team provides a valuable experience to our members both in the engineering process and practical skills, and we hope that you consider us for a sponsorship.

- Comments(1)

- Likes(1)