|

Altium DesignerAltium Designer

|

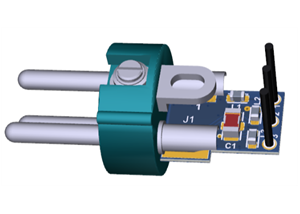

KM84++ for Takstar CM-63 Microphone

Before going into the project details, an important note: when you order the PCB, choose a thickness of 1.2mm! Otherwise, it will not fit between the XLR pins and the nose cone.

The vintage Neumann KM84 is a popular microphone to build because of its legendary status and simple circuitry. However, the design has a disadvantage that some find annoying: It is susceptible to cell phone interference. This design pays extra attention to suppressing this interference. Please take a look at the references at the bottom of this building instruction for a detailed circuit description. I would strongly recommend reading these articles first if you want to deviate from the BOM I've included here. Other advantages of the KM84++ over the classic KM84 circuit and my KM84+ circuit are the lower noise and distortion.

This PCBA uses mainly SMT components because this is the only way to get a good working cell phone interference suppression. It also solves the problem of the increasingly scarce availability of good JFETs. I have used as many "large", DIY-friendly SMTs as possible. However, if you are apprehensive about soldering these, consider using the PCBWay Assembly service. And solder the wired components yourself. For components you might want to experiment with, I have used wired components where possible.

Before we get into the assembly instructions, let's first briefly talk about component selection.

- If you don't know which transformer to use, I would like to refer you to the KM84 circuit description, the link to which is listed under references. Don’t ask me which one sounds best: I have only used the ASTDS T-8 and I’m happy with it.

- Unfortunately, the XLR insert that is in the BOM and offers the best RFI suppression is only available per 100 pieces. Alternatively, use this XLR insert: https://www.aliexpress.us/item/2251832761131816.html?spm=a2g0o.order_list.order_list_main.25.fc5b1802Iu9vnq&gatewayAdapt=glo2usa4itemAdapt

- The BOM contains a mix of multiple manufacturers of SMT resistors. You can use any manufacturer of Thick-film resistors that Mouser or Digikey offers, as long as you keep the same value and tolerance. There is absolutely no point in using precision Thin-Film resistors. Do not expect a better sound quality or less noise from such resistors. The low noise of Thin-Film resistors only applies to the so-called excess noise, or 1/f noise, which only occurs at very low frequencies, to which our hearing has a very low sensitivity. The thermal (Johnson) noise is the same for all resistors. Only for R9 and R10, you’ll want to use precision 0.1% resistors, but they are also available as Thick-Film. Alternatively, from a batch of 2k2 1% resistors, select a pair that matches within 0.1% for the best CMRR (i.e. best mains hum rejection).

- The same goes for the capacitors: you can use other brands if you follow the Description when selecting the components. For capacitors in the audio path, you want to use C0G/NP0 ceramic capacitors, film, or good-quality electrolytic capacitors. I have no reason to believe that special audio capacitors lead to better sound quality, other than the placebo effect. But everyone has their own opinion on this, and if you think that other types than those listed give a better result, feel free to experiment with them.

- There is no need to select the JFET because the bias current can be adjusted through a trimmer potmeter. It is not likely, but also not impossible, that the gains of two JFETs from one reel differ so much that the gains of two PCBAs differ by more than 0.5 dB.

- For the nose cone, you can use the one from the CM-63 PCBA. Or you can use the 3D-printed nose cone that can be ordered from PCBWay through this link: https://www.pcbway.com/project/shareproject/Takstar_CM_60_and_CM_63_nose_cone_272ff5ee.html

- If you chose assembly by PCBWay, do not allow the use of parts other than the original ones from Mouser or Digikey. Some parts may be out of stock at one distributor. If so, then search for the same item at the other. Or post your doubts or questions in this GroupDIY thread.

Assembly Instructions:

If you are not experienced in soldering SMT components, consider ordering the PCBA with the SMT components already assembled by PCBWay. I have provided the Centroid pick-and-place file listing all the SMT components. When placing the components, carefully watch the assembly drawings provided! Especially R1, R2 and C1 need some attention because I left out the silkscreen printing from the High-Z area with the guard ring. The 3D PDF provided may be of help too when placing the parts.

- Solder the XLR insert to the PCB. Make sure the PCB and XLR are exactly perpendicular to each other. Solder one pin with a small amount of solder until you are sure they are indeed perpendicular to each other.

- If you are using the 3D-printed nose cone as described above, mount it as described.

- Solder the SMT parts from small to big. Solder the JFET as the last component.

- Solder the through-hole parts. The 3-pin header is optional and only needed if you want to be able to switch between low-cut filter slopes. Else, solder a wire to permanently select between either of the two options. The same applies to trimmer P1: only if you want to have adjustable sensitivity of the microphone to make matched pairs, you would want to mount P1. If you do not mount P1, then jumper the trimmer with a wire between the two outer pins.

- Solder the transformer to the PCBA. You may want to cut the excess length of the transformer leads. The primary side connections are marked on the PCB with Prim and the secondary side with Sec. The start of the winding is indicated with a dot. Your transformer datasheet should provide this information.

- Near the XLR insert, there is a Chassis ground connection. If your solder iron has enough power to solder a wire to the mic body tail part, you can solder a wire from here to the tail part for improved RFI rejection.

- Connect the PCBA to a P48 Phantom power supply, mixer or preamp. Connect a voltmeter between the ground and Bias test terminals. Wait ~1 minute for the bias current to settle. Adjust P2 until the Bias voltage reads ~11V. The original KM84 should be adjusted to 10V, but in this circuit, the JFET stage operates from a slightly higher supply voltage for more headroom and should be adjusted to 11V.

- Alternatively, use a good-quality Audio Interface and REW to adjust P2 until the lowest THD is obtained, or symmetrical clipping is achieved. Whatever you like…

- Mount the slider switch knobs. You can use the ones from the original CM-63 PCBA.

- Clean the PCBA with Isopropyl Alcohol. At least the area with the JFET and GOhm resistors must be cleaned thoroughly. Apply IPA, then clean with a brush, and finally rinse with IPA again. Dry with a heat gun or hair dryer.

- Assemble the complete microphone. After assembly has been completed, you should perform a polarity check to ensure you have not accidentally swapped the transformer wires. I will describe more methods on my website, but one simple way is to have a known-good mic and your DIY mic hooked up to a mixer. Speak into one mic at a time and adjust the gain until you hear both mics at an equal level through the headphone monitoring output. Then keep both mics next to each other and speak into both mics. The level should now be louder than when speaking into one mic. If it is softer, the polarity of your DIY mic must be inverted by swapping the wires on either the primary or secondary side of the transformer.

- Enjoy your DIY KM84 microphone!

References:

KM84 Circuit Description: https://modimications.com/km84-style-charge-amplifier-circuit/

KM84++ Circuit Description: https://modimications.com/km84-and-km84-head-amp-circuits/

GroupDIY thread that led to this design: https://groupdiy.com/threads/is-there-a-way-to-reduce-cell-phone-interference-in-diy-km-84.86707/

KM-84 Clone – Blind Test thread: https://groupdiy.com/threads/four-km-84-clones-blind-test.89135/

List of other microphone PCBs: https://modimications.com/all-orderable-pcbs/

Addendum, Change History:

- 2025-03-29: BOM and schematic updated. MPN of C11 was changed by the manufacturer. Schematic and BOM are now displaying the new MPN. Voltage rating of C14, C15 and C16 erroneously displayed as 100V. It should read 50V. In the Notes section at the bottom of the BOM I have listed some alternative components.

- 2025-04-07: The MPN of the alternative part for C11 which I mentioned in the Notes section of the BOM has been updated. I accidentally mentioned the MPN of a feed-through capacitor, instead of an X2Y capacitor.

KM84++ for Takstar CM-63 Microphone

*PCBWay community is a sharing platform. We are not responsible for any design issues and parameter issues (board thickness, surface finish, etc.) you choose.

- Comments(0)

- Likes(13)

-

Engineer

Dec 22,2025

Engineer

Dec 22,2025

-

Pablo Picasso

Nov 04,2025

Pablo Picasso

Nov 04,2025

-

Paweł M. Falcman

Oct 27,2025

Paweł M. Falcman

Oct 27,2025

-

Engineer

Oct 23,2025

Engineer

Oct 23,2025

-

Engineer

Jul 24,2025

Engineer

Jul 24,2025

-

Engineer

Jul 13,2025

Engineer

Jul 13,2025

-

Engineer

Mar 19,2025

Engineer

Mar 19,2025

-

Engineer

Jan 21,2025

Engineer

Jan 21,2025

-

Engineer

Dec 29,2024

Engineer

Dec 29,2024

-

Engineer

Dec 28,2024

Engineer

Dec 28,2024

-

Jethro Karsters

Dec 25,2024

Jethro Karsters

Dec 25,2024

-

Engineer

Dec 24,2024

Engineer

Dec 24,2024

-

Michael Willis

Dec 23,2024

Michael Willis

Dec 23,2024

- 0 USER VOTES

- YOUR VOTE 0.00 0.00

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

More by Jan Postma

More by Jan Postma

-

Condenser Microphone RFI Filter

This little PCB contains an RF Interference filter that has been optimised to suppress cell phone in...

Condenser Microphone RFI Filter

This little PCB contains an RF Interference filter that has been optimised to suppress cell phone in...

-

Takstar CM-60 and CM-63 nose cone

For this nose cone design, you will need to acquire the following parts:This Nose Cone.4 mm outside,...

Takstar CM-60 and CM-63 nose cone

For this nose cone design, you will need to acquire the following parts:This Nose Cone.4 mm outside,...

-

KM84++ for Takstar CM-63 Microphone

Before going into the project details, an important note: when you order the PCB, choose a thickness...

KM84++ for Takstar CM-63 Microphone

Before going into the project details, an important note: when you order the PCB, choose a thickness...

-

Slide switch knob for Takstar CM-60 compatible DIY PCBA builds

This slide switch knob can be used for DIY PCBAs that fit the Takstar CM-60 condenser microphone. If...

Slide switch knob for Takstar CM-60 compatible DIY PCBA builds

This slide switch knob can be used for DIY PCBAs that fit the Takstar CM-60 condenser microphone. If...

-

KM84+ for Takstar CM-60

Before going into the project details, an important note: when you order the PCB, choose a thickness...

KM84+ for Takstar CM-60

Before going into the project details, an important note: when you order the PCB, choose a thickness...

-

-

mammoth-3D SLM Voron Toolhead – Manual Drill & Tap Edition

252 0 0 -

-

AEL-2011 Power Supply Module

780 0 2 -

AEL-2011 50W Power Amplifier

647 0 2 -

-

-

Custom Mechanical Keyboard

841 0 0 -

Tester for Touch Screen Digitizer without using microcontroller

463 2 2 -

Audio reactive glow LED wristband/bracelet with NFC / RFID-Tags

408 0 1 -

-