Stanley A Meyer 9 Tube Wfc Spacer 3d print

Stanley A Meyer 9 Tube Wfc Spacer 3d print

JOIN US HERE

LEARN EVERYTHING BE A GLOBAL MASTER WITH US

NANO BUBBLEWATER FUEL

https://www.patreon.com/c/securesupplies/shop

Daniel's kind-hearted approach and dedication to a cleaner energy future deserve recognition and support.

JOIN SUPPORT LEARN MORE HERE https://www.patreon.com/c/securesupplies

You can contribute to his ongoing efforts by donating through PayPal at https://www.paypal.com/donate/?hosted_button_id=29MNNNGUSBQXW

Additionally, joining his Builder Level on Patreon at https://www.patreon.com/c/securesupplies grants you access to exclusive updates, resources, and a community of like-minded supporters dedicated to advancing hydrogen technology.

By supporting his work, you join in the journey toward a sustainable future. Godspeed, Daniel Donatelli!

The Stanley A. Meyer 9-Cell Water Fuel Cell (WFC) Tube Holder Plate (Top) played an essential role in securing the 9-tube arrangement in place, especially in a moving vehicle like Meyer’s dune buggy. The top holder plate was a crucial design element engineered to provide structural support, optimize water and gas flow, and ensure electrical isolation between the tubes.

Key Functions of the Tube Holder Plate (Top)

Structural Support and Stability:

The top plate was designed to firmly hold each of the 9 tubes, preventing them from moving due to vibrations or the G-forces experienced while driving. This was essential for maintaining stability in the cell’s design, as any shift in the alignment of the tubes could impact the efficiency of gas production.

The holder plate typically used a durable, non-conductive material (such as plastic or composite material) to avoid short-circuiting while still offering strong structural support.

By keeping the tubes securely fastened, the top plate minimized the risk of mechanical stress or fractures, particularly given the high-frequency vibrations of the pulsed high-voltage system that Meyer used.

Tube Separation for Electrical Insulation:

The 9-cell WFC relies on the capacitor-like structure formed between each pair of inner and outer tubes. The holder plate keeps each pair properly separated to prevent electrical arcing or shorting between tubes, which could damage the cell or disrupt the pulsing circuit’s effectiveness.

Proper spacing also ensures that the electric field created by each tube pair remains isolated, optimizing the voltage differential across the water in the gap, which aids in efficient gas production.

Water Flow and Level Control:

Meyer’s design was aimed at achieving efficient water fracturing. The tube holder plate (top) was engineered with precise gaps or cutouts to allow water to flow freely between the tubes, ensuring that each cell remained submerged at a controlled level.

The open structure of the top plate prevented any restriction in water flow, allowing the tubes to refill quickly with water as it was split into hydrogen and oxygen gas, maintaining continuous operation without water level fluctuations that could impair gas output.

Gas Flow and Collection:

The plate’s design facilitated upward gas flow by allowing the hydrogen and oxygen nano-bubbles generated between the tubes to rise naturally toward the top of the cell. This arrangement enabled the collection and venting of gases from the upper part of the WFC without obstructing their path.

Additionally, by keeping the tubes in a fixed position with open space around them, Meyer ensured that gas bubbles wouldn’t get trapped between the tubes, which could reduce efficiency or lead to safety issues due to gas buildup.

G-Force and Vibration Resistance:

In a vehicle application, Meyer’s WFC was subjected to various G-forces and mechanical stresses, especially in an off-road environment like his dune buggy. The top holder plate was specifically engineered to keep the tubes aligned and immovable despite these forces, allowing for stable operation even when the vehicle encountered rough terrain.

By using a robust mounting system for the holder plate, Meyer ensured that the tubes would remain in precise alignment, which was critical for maintaining the correct spacing and resonance needed for effective voltage pulsing and gas production.

Design Details of the Tube Holder Plate

Material Choice: Typically, the holder plate was made of a non-conductive, rigid material like acrylic, Teflon, or high-grade plastic. This not only provided electrical insulation but also ensured durability against both physical stress and exposure to water and gases.

Size and Spacing: The plate was sized to accommodate the specific diameter and height of each tube, ensuring that the tubes remained vertically aligned. The spacing was calculated to allow for the ideal gap between inner and outer tubes while preventing any contact between adjacent tube pairs.

Gas and Water Openings: Strategic openings or slots in the plate allowed for unrestricted flow of water and gases. These openings were positioned to allow gas bubbles to rise directly to the top, where they could be collected or vented, and for water to circulate easily between the tubes, sustaining the cell’s electrolyte environment.

Importance of the Tube Holder Plate in the 9-Cell WFC System

The tube holder plate (top) was crucial for several reasons:

It ensured consistent performance by keeping the tubes in precise alignment, which is critical for resonance and efficient energy transfer.

It provided safety by preventing unwanted electrical contact or arcing between tube pairs, maintaining the integrity of the high-voltage system.

It maintained operational stability under driving conditions, which is essential for any practical vehicular fuel cell application.

It allowed for optimal gas output by facilitating the unobstructed flow and collection of hydrogen and oxygen gases, preventing buildup that could lead to inefficiency or risk of flashback.

In summary, the Stanley A. Meyer 9-Cell WFC Tube Holder Plate (Top) served as a multi-functional component that held the tubes securely, ensured the correct spacing for optimal voltage pulsing, allowed water and gas to flow freely, and provided the necessary stability for mobile applications. By carefully engineering this part, Meyer was able to create a resilient and efficient water-splitting cell that could operate reliably even in the dynamic environment of his hydrogen-powered vehicle.

Stanley A Meyer 9 Tube Wfc Spacer 3d print

*PCBWay community is a sharing platform. We are not responsible for any design issues and parameter issues (board thickness, surface finish, etc.) you choose.

- Comments(0)

- Likes(1)

-

Daniel Donatelli

Nov 08,2024

Daniel Donatelli

Nov 08,2024

- 0 USER VOTES

- YOUR VOTE 0.00 0.00

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

More by Daniel Donatelli

More by Daniel Donatelli

-

Stanley A Meyer VIC Voltage intensifier circuit transformer board v1.8 updated jan 11 2021

Stanley A Meyer VIC Voltage intensifier transformer board Join Support help change the World https:/...

Stanley A Meyer VIC Voltage intensifier circuit transformer board v1.8 updated jan 11 2021

Stanley A Meyer VIC Voltage intensifier transformer board Join Support help change the World https:/...

-

STANLEY A MEYER LES BANKI AUTO START AUTO WATER FUEL REFILL

STANLEY A MEYER LES BANKI AUTO START AUTO WATER FUEL REFILLJoin Support help change the World https:...

STANLEY A MEYER LES BANKI AUTO START AUTO WATER FUEL REFILL

STANLEY A MEYER LES BANKI AUTO START AUTO WATER FUEL REFILLJoin Support help change the World https:...

-

Stanley A Meyer Gated Pulse Frequency Generator K3 with DB 37 updated 060622

Stanley A Meyer Gated Pulse Frequency Generator K3 with DB 37 to suit matrix vic main board Join Sup...

Stanley A Meyer Gated Pulse Frequency Generator K3 with DB 37 updated 060622

Stanley A Meyer Gated Pulse Frequency Generator K3 with DB 37 to suit matrix vic main board Join Sup...

-

Stanley A Meyer K2 Variable Pulse Frequency Generator GMS Vic Matrix PCB Gerber

Stanley A Meyer K2 Variable Pulse Frequency Generator GMS Vic Matrix PCBGerberJoin Support help chan...

Stanley A Meyer K2 Variable Pulse Frequency Generator GMS Vic Matrix PCB Gerber

Stanley A Meyer K2 Variable Pulse Frequency Generator GMS Vic Matrix PCBGerberJoin Support help chan...

-

Hyduino Stim Stimulator circuit board Ms EMS ECU

Hyduino Stim Stimulator circuit board Ms EMS ECUJoin Support help change the World https://www.patre...

Hyduino Stim Stimulator circuit board Ms EMS ECU

Hyduino Stim Stimulator circuit board Ms EMS ECUJoin Support help change the World https://www.patre...

-

Stanley A Meyer VIC Daughter Board Driver Transistor Circuit board Version 1

Stanley A Meyer VIC Daughter Board Driver Transistor Circuit board Version 1 Updated 28th Sept 2021 ...

Stanley A Meyer VIC Daughter Board Driver Transistor Circuit board Version 1

Stanley A Meyer VIC Daughter Board Driver Transistor Circuit board Version 1 Updated 28th Sept 2021 ...

-

Stanley A Meyer VIC Daughter Board Driver USed with Variac EEC eleectron eextrract & chokes

Stanley A Meyer VIC Daughter Board Driver USed with Variac EEC eleectron extrract & chokes can d...

Stanley A Meyer VIC Daughter Board Driver USed with Variac EEC eleectron eextrract & chokes

Stanley A Meyer VIC Daughter Board Driver USed with Variac EEC eleectron extrract & chokes can d...

-

Stanley A Meyer Fuel Line Insert WFC Nano Bubble Water Fuel Cell V3

Stanley A Meyer WFC Nano Bubble Water Fuel Cell V3 Barbed Fuel Line insert Stanley a Meyer WFC Nano ...

Stanley A Meyer Fuel Line Insert WFC Nano Bubble Water Fuel Cell V3

Stanley A Meyer WFC Nano Bubble Water Fuel Cell V3 Barbed Fuel Line insert Stanley a Meyer WFC Nano ...

-

Stanley A Meyer Nano Bubble Water Fuel Cell WFC Parts 2026 V2

Stanley a Meyer WFC Nano Bubble Water Fuel Cell Single Cell 2026Stanley a Meyer Single Cell 2026This...

Stanley A Meyer Nano Bubble Water Fuel Cell WFC Parts 2026 V2

Stanley a Meyer WFC Nano Bubble Water Fuel Cell Single Cell 2026Stanley a Meyer Single Cell 2026This...

-

Stanley a Meyer WFC Nano Bubble Water Fuel Cell Single Cell 2026

Stanley a Meyer Single Cell 2026This is a work to make it faster easier for every one to get the cel...

Stanley a Meyer WFC Nano Bubble Water Fuel Cell Single Cell 2026

Stanley a Meyer Single Cell 2026This is a work to make it faster easier for every one to get the cel...

-

2025 Stanley A Meyer Egan Half Bridge Switch VOLTROLYSIS

2025 Stanley A Meyer Egan Half Bridge Switch VOLTROLYSISJoin the Builder LevelBy joining the Builder...

2025 Stanley A Meyer Egan Half Bridge Switch VOLTROLYSIS

2025 Stanley A Meyer Egan Half Bridge Switch VOLTROLYSISJoin the Builder LevelBy joining the Builder...

-

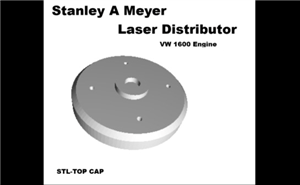

Stanley A Meyer vw 1600 Cap Laser Distributor

Stanley A Meyer vw 1600 Cap Laser DistributorVideo https://youtu.be/XQd8zwEA4LE?si=dpG4jgLsHhYTkX5cJ...

Stanley A Meyer vw 1600 Cap Laser Distributor

Stanley A Meyer vw 1600 Cap Laser DistributorVideo https://youtu.be/XQd8zwEA4LE?si=dpG4jgLsHhYTkX5cJ...

-

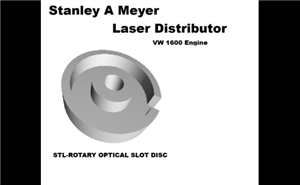

Stanley A Meyer vw 1600 STL-ROTARY OPTICAL SLOT DISC

Stanley A Meyer vw 1600 STL-ROTARY OPTICAL SLOT DISCVideo https://youtu.be/XQd8zwEA4LE?si=dpG4jgLsHh...

Stanley A Meyer vw 1600 STL-ROTARY OPTICAL SLOT DISC

Stanley A Meyer vw 1600 STL-ROTARY OPTICAL SLOT DISCVideo https://youtu.be/XQd8zwEA4LE?si=dpG4jgLsHh...

-

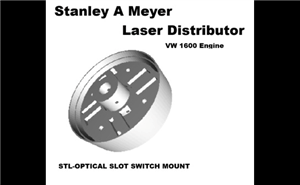

Stanley A Meyer vw 1600 STL-OPTICAL SLOT SWITCH MOUNT

Stanley A Meyer vw 1600 STL-OPTICAL SLOT SWITCH MOUNTVideo https://youtu.be/XQd8zwEA4LE?si=dpG4jgLsH...

Stanley A Meyer vw 1600 STL-OPTICAL SLOT SWITCH MOUNT

Stanley A Meyer vw 1600 STL-OPTICAL SLOT SWITCH MOUNTVideo https://youtu.be/XQd8zwEA4LE?si=dpG4jgLsH...

-

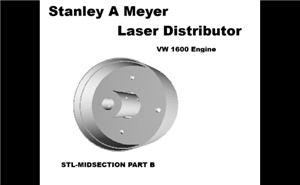

Stanley Meyer Laser VW 1600 Buggy Distributor STL-MIDSECTION PART B

Stanley Meyer Laser VW 1600 Buggy Distributor STL-MIDSECTION PART BVideo https://youtu.be/XQd8zwEA4L...

Stanley Meyer Laser VW 1600 Buggy Distributor STL-MIDSECTION PART B

Stanley Meyer Laser VW 1600 Buggy Distributor STL-MIDSECTION PART BVideo https://youtu.be/XQd8zwEA4L...

-

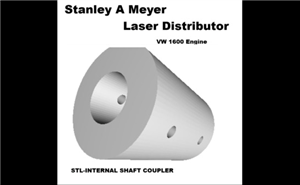

Stanley Meyer Laser VW 1600 Buggy Distributor STL-INTERNAL SHAFT COUPLER

Stanley Meyer Laser VW 1600 Buggy Distributor STL-INTERNAL SHAFT COUPLER Video https://youtu.be/XQd8...

Stanley Meyer Laser VW 1600 Buggy Distributor STL-INTERNAL SHAFT COUPLER

Stanley Meyer Laser VW 1600 Buggy Distributor STL-INTERNAL SHAFT COUPLER Video https://youtu.be/XQd8...

-

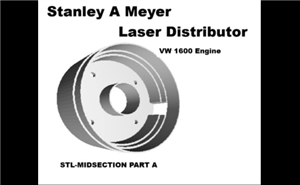

Stanley Meyer Laser VW 1600 Buggy Distributor STL-MIDSECTION PART A

Stanley Meyer Laser VW 1600 Buggy STL-MIDSECTION PART A Video https://youtu.be/XQd8zwEA4LE?si=dpG4jg...

Stanley Meyer Laser VW 1600 Buggy Distributor STL-MIDSECTION PART A

Stanley Meyer Laser VW 1600 Buggy STL-MIDSECTION PART A Video https://youtu.be/XQd8zwEA4LE?si=dpG4jg...

-

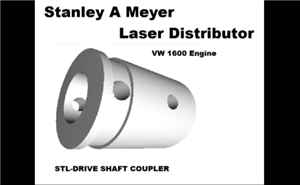

Stanley Meyer Laser VW 1600 Buggy Distributor STL-DRIVE SHAFT COUPLER (1)

Stanley Meyer Laser VW 1600 Buggy Distributor Video https://youtu.be/XQd8zwEA4LE?si=dpG4jgLsHhYTkX5c...

Stanley Meyer Laser VW 1600 Buggy Distributor STL-DRIVE SHAFT COUPLER (1)

Stanley Meyer Laser VW 1600 Buggy Distributor Video https://youtu.be/XQd8zwEA4LE?si=dpG4jgLsHhYTkX5c...

-

-

mammoth-3D SLM Voron Toolhead – Manual Drill & Tap Edition

252 0 0 -

-

AEL-2011 Power Supply Module

779 0 2 -

AEL-2011 50W Power Amplifier

646 0 2 -

-

-

Custom Mechanical Keyboard

839 0 0 -

Tester for Touch Screen Digitizer without using microcontroller

462 2 2 -

Audio reactive glow LED wristband/bracelet with NFC / RFID-Tags

407 0 1 -

-