The perfect amplifier?

Semiconductor Manufacturing and Quality Control

Manufacturing semiconductors is complex and requires strict quality control. If corners are cut or quality isn’t enforced, the result is defective semiconductors that can create excessive noise. Early in the history of South Korea's electronics industry, the circuits and engineers were competent, but the low-quality semiconductors and electronic components they used led to subpar products. However, over time, significant advancements have been made, and today South Korea is known for producing high-quality electronics with minimal noise. Modern high-quality transformers are so quiet that it can be difficult to tell if they are operating.

While the quality of most components has drastically improved, substandard parts still pose serious challenges. Using low-quality components in a Class D amplifier or switch-mode power supply, for instance, can lead to serious noise issues and instability. Even with high-quality parts, grading and burn-in tests may be necessary to sort out defective components.

Dominant Poles and Semiconductor Quality in Electronics

In high-power electronics and audio systems, dominant poles and component quality play an essential role. Faulty semiconductors can behave like oscillators, producing structural noise and high sound pressure levels (SPL) with minimal energy input. This section explores the historical challenges, the evolution of semiconductor technology, the importance of break-in periods, and strategies for managing dominant poles to improve component quality.

Early solid-state and Class D amplifiers faced challenges with noise and distortion due to low-quality semiconductors. Vacuum tube technology, which has a more linear amplification characteristic and greater tolerance to imperfections, initially remained competitive. The material inconsistencies and defects in early semiconductors led to unpredictable performance, switching noise, and "Class D glare." Poor filtering techniques compounded these issues, making it difficult to achieve clean audio outputs.

Today, advancements in semiconductor technology have largely addressed these issues. Modern semiconductors feature high material consistency and precision manufacturing, leading to reduced noise and enhanced performance. Advanced filtering techniques, such as low-pass filters and digital signal processing (DSP), help suppress switching noise in Class D amplifiers and digital power supplies. DSP can also manage noise and improve signal integrity in real-time.

Break-In Period and Component Performance

"Break-in" refers to the stabilization period for electronic components after initial use. This is important for semiconductors and capacitors, as they may show improved performance over time. Electrolytic capacitors, in particular, benefit from a break-in period where the dielectric material stabilizes, enhancing performance. Film and ceramic capacitors may also exhibit improved characteristics after brief electrical conditioning.

Dominant Poles and Their Management

Dominant poles are critical frequencies where minimal energy input can cause a device to resonate, potentially leading to noise and performance issues. In speaker systems, the resonance frequency (Fs) is a dominant pole that can cause unwanted resonances. Similarly, in semiconductors, the transition frequency (ft) is a dominant pole where gain drops significantly, possibly leading to instability. Strategies such as using damping materials, notch filters, and structural reinforcements can help manage these resonances in both speaker and semiconductor systems.

Noise Issues and Solutions in High-Performance Semiconductors

Semiconductors involved in high-frequency applications, such as Class D amplifiers or digital power supplies, can generate ultrasonic structural noise due to mechanical vibrations and thermal fluctuations. This noise, often caused by the piezoelectric effect or rapid heating and cooling, can lead to acoustic noise that degrades device performance.

Dampers and heat spreaders are two key solutions to this problem. Dampers absorb mechanical energy, reducing vibrations, while heat spreaders manage thermal gradients by evenly distributing heat across the semiconductor. Together, they reduce both mechanical and thermal-induced noise, improving device reliability and extending the lifespan of components.

Hearing Mechanics and Subwoofer Perception

The mechanics of hearing involve a complex chain of processes, including sound localization, amplification, and signal interpretation by the brain. These processes are subject to distortion and variation, meaning that even the same sound can be perceived differently by different people.

An interesting analogy can be drawn between sound pressure levels (SPL) and frequency in relation to the human body. Just as high stress levels damage joints over time, very high SPL levels can cause permanent hearing damage. As people age, they lose the ability to hear higher frequencies, similar to how older individuals lose the ability to run as fast as younger ones. Health and hearing are intimately related.

When comparing sealed and ported subwoofers, the brain perceives sound from ported subwoofers as louder and deeper than from sealed subwoofers, even if they have the same SPL and frequency output. Therefore, ported subwoofers are often preferred for parties or movies, while sealed subwoofers are better suited for critical listening environments.

Amplifier Design and Gain Stages

Each amplifier has its own distinct sound and character. Total harmonic distortion (THD) alone is not always indicative of an amplifier's overall quality. Amplifier stages introduce losses, and each stage must contribute either voltage or current gain to achieve optimal fidelity.

The Long-Tailed Pair (LTP) configuration, often used in amplifiers, can achieve gains of 6dB to 20dB, with typical designs focusing on 13dB of current gain. For precision, a Class A buffer can be used to further improve the accuracy of the input signal. The VAS (voltage amplifier stage) is where most of the voltage gain occurs, and in some designs, current gain is kept between 6dB to 9dB, with the LTP current serving as the reference.

For optimal performance, biasing, particularly in AB output switching stages, should be carefully managed. The first watt should be biased into Class A operation, with subsequent stages appropriately biased for efficiency and fidelity.

Conclusion

Dominant poles, component quality, and proper design practices are crucial to the performance and reliability of high-power electronics and audio systems. The early struggles with substandard semiconductors highlighted the need for stringent quality control, grading, and advanced design techniques. Modern advancements, combined with rigorous testing and filtering techniques, have greatly improved the performance of electronic systems.

Understanding and managing dominant poles, break-in processes, and structural noise are vital for creating high-performance, reliable electronic products. Advanced materials, DSP techniques, and quality control measures ensure that modern components meet the highest performance standards.

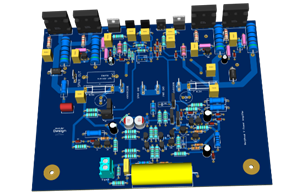

Amplifiers may have different characteristics in handling different genres of music based on the amplifiers topology and choice of gain distribution, the figure below comes in handy

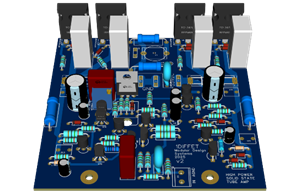

Managing output stage oscillation as shown below

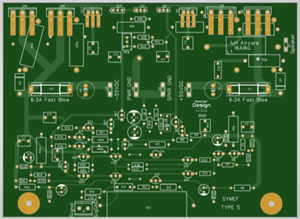

Effects of adding equalization in the feedback network

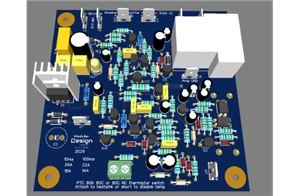

Comparing voltage and current references

Use headphones when evaluating these sound samples, is there a difference? What causes the differences, could it be the cables, the different amplifiers?

https://www.youtube.com/watch?v=VFLjDyhdZ-I

https://www.youtube.com/watch?v=Qkjsd6DY8FY

https://www.youtube.com/watch?v=n-1W28gJ9g4

https://www.youtube.com/watch?v=Ny5tYl6HHvc

https://www.youtube.com/watch?v=ugJt7nmDEfs

https://www.youtube.com/watch?v=z131aMr6zHg

https://www.youtube.com/watch?v=Jda__tVBMgQ

The perfect amplifier?

- Comments(1)

- Likes(0)

- 0 USER VOTES

- YOUR VOTE 0.00 0.00

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

More by ModularDesignSystems Harrison

More by ModularDesignSystems Harrison

-

SYMPHONY audio power amplifier

Ensure you download the right Gerber. There are two Gerber files. One for single opamp and the other...

SYMPHONY audio power amplifier

Ensure you download the right Gerber. There are two Gerber files. One for single opamp and the other...

-

SYMEF Audio Power Amplifier

SYMEF audio power amplifier v2024170.05mm * 124.4mmOrder through PCBWAYUSER FEEDBACK... Extreme grip...

SYMEF Audio Power Amplifier

SYMEF audio power amplifier v2024170.05mm * 124.4mmOrder through PCBWAYUSER FEEDBACK... Extreme grip...

-

Heddie Amp

A headphone amplifier for 33 ohm to 600 ohm headphones

Heddie Amp

A headphone amplifier for 33 ohm to 600 ohm headphones

-

3Way Crossover Board

3 way passive crossover with good phase can use two sided PCB.

3Way Crossover Board

3 way passive crossover with good phase can use two sided PCB.

-

Morpheus V audio power amplifier

Following the success of Morpheus IV here's the bigger brother Morpheus V 183.26 mm* 146.3 mm

Morpheus V audio power amplifier

Following the success of Morpheus IV here's the bigger brother Morpheus V 183.26 mm* 146.3 mm

-

AC auto voltage select and protect

AC auto voltage select and protect, under voltage , over voltage protect

AC auto voltage select and protect

AC auto voltage select and protect, under voltage , over voltage protect

-

Amplifier Chassis 3U Two Piece

Amplifier Chassis 3U Two Piece, 1.2mm powder coatSuperiorSpill prooflighter

Amplifier Chassis 3U Two Piece

Amplifier Chassis 3U Two Piece, 1.2mm powder coatSuperiorSpill prooflighter

-

mosfet amplifier

An amplifier thats good to go, getting in their with the worlds best while looking cool 100mmx100mm....

mosfet amplifier

An amplifier thats good to go, getting in their with the worlds best while looking cool 100mmx100mm....

-

Pot luck amplifier

Pot luck amplifier, minimum compensation, soft clipping, can match up to most amplifiers

Pot luck amplifier

Pot luck amplifier, minimum compensation, soft clipping, can match up to most amplifiers

-

The perfect amplifier?

Semiconductor Manufacturing and Quality ControlManufacturing semiconductors is complex and requires ...

The perfect amplifier?

Semiconductor Manufacturing and Quality ControlManufacturing semiconductors is complex and requires ...

-

SYMEF type S

When evaluating and measuring audio we sometimes forget the brain is its own computer that applies i...

SYMEF type S

When evaluating and measuring audio we sometimes forget the brain is its own computer that applies i...

-

Balanced input

Balanced audio input suitable for both balanced and unbalanced inputs

Balanced input

Balanced audio input suitable for both balanced and unbalanced inputs

-

Passive preamplifier

A passive preamplifier suitable for all types of power amplifiers

Passive preamplifier

A passive preamplifier suitable for all types of power amplifiers

-

First Class Amplifier chassis

First Class Amplifier chassis1.5mm base plate galvanized steel gauge 164mm aluminum 6061/6063 front ...

First Class Amplifier chassis

First Class Amplifier chassis1.5mm base plate galvanized steel gauge 164mm aluminum 6061/6063 front ...

-

Amplifier power supply board

Amplifier power supply board, measures 200.03mm * 106.81mm

Amplifier power supply board

Amplifier power supply board, measures 200.03mm * 106.81mm

-

speaker protection - intermediate

Speaker protection can be used for true duo mono DC, Delay, temperature, over currentOver current pr...

speaker protection - intermediate

Speaker protection can be used for true duo mono DC, Delay, temperature, over currentOver current pr...

-

power supply soft start

Measures 99.82mm * 91.57mm , use either 1oz or 2oz copper

power supply soft start

Measures 99.82mm * 91.57mm , use either 1oz or 2oz copper

-

Phono Power Supply

Groove phono power supply 198.88mm * 61.98mm, can use 1oz copper

Phono Power Supply

Groove phono power supply 198.88mm * 61.98mm, can use 1oz copper

-

-

mammoth-3D SLM Voron Toolhead – Manual Drill & Tap Edition

242 0 0 -

-

AEL-2011 Power Supply Module

769 0 2 -

AEL-2011 50W Power Amplifier

638 0 2 -

-

-

Custom Mechanical Keyboard

831 0 0 -

Tester for Touch Screen Digitizer without using microcontroller

454 2 2 -

Audio reactive glow LED wristband/bracelet with NFC / RFID-Tags

403 0 1 -

-