ARDUINO BASED SMART SOLDERING STATION WITH LCD

Introduction

The Arduino Nano-based soldering station is a comprehensive, feature-rich tool designed for precision and ease of use in soldering tasks. Leveraging the compact and powerful Arduino Nano microcontroller. This versatile soldering station is ideal for hobbyists, DIY enthusiasts, and professionals seeking a reliable and customizable solution for their soldering needs.

For Full Project :

https://electronicsworkshops.com/2024/04/30/title/

Features

Rotary Encoder Support: Designed to interface seamlessly with rotary encoders for precise temperature control.

Built-in Beeper: Includes an onboard beeper for audio feedback, enhancing user interaction.

Memory Buttons: Equipped with built-in memory buttons allowing the user to store and recall frequently used temperature settings.

Supports up to 7 buttons, with 3 buttons integrated on the board.

Debouncing: Built-in debouncing mechanism for all buttons to ensure accurate and reliable button presses.

Temperature Reading: Utilizes a MAX6675 module for accurate temperature readings from a K-type thermocouple, ensuring precise temperature control.

LCD Header: Includes a header designed for an I2C LCD module, allowing for easy connection and display of temperature readings and settings.

Motion Sensing: Integrates motion sensing using the soldering iron’s mercury switch to detect movement. This feature can be used to automatically manage power or temperature settings based on activity.

Dimmable LCD Backlight: Provides a dimmable backlight for the LCD, offering adjustable visibility in various lighting conditions.

Feedback LED Header: Includes a header for connecting a feedback LED, which can be used for status indication or alerts.

Working Principle of Arduino-Based Smart Soldering Station

The Arduino-based smart soldering station operates by integrating various components to control and monitor the soldering process, ensuring precision and efficiency. Here’s a detailed explanation of its working principle:

Microcontroller (Arduino Nano)

Core Function: The Arduino Nano serves as the central processing unit. It reads inputs from various sensors and controls the output to maintain the desired temperature.

Programming: The Arduino is programmed with a code that handles all operations, from reading the temperature to updating the display and controlling the heating element.

Temperature Sensing (MAX6675 Module and K-type Thermocouple)

Thermocouple: The K-type thermocouple is attached to the soldering iron’s tip and measures the temperature.

MAX6675 Module: This module converts the analog signals from the thermocouple into digital values that the Arduino can read.

Reading Temperature: The Arduino reads the digital temperature data from the MAX6675 module periodically to monitor the current temperature of the soldering iron.

User Interface (Rotary Encoder and Buttons)

Rotary Encoder: Used for setting the desired temperature. Rotating the encoder changes the target temperature, while pressing it can select or confirm settings.

Buttons: Additional buttons can store and recall frequently used temperature settings, allowing for quick adjustments.

Display (I2C LCD)

LCD Module: An I2C LCD module displays the current and target temperatures, along with other status information.

Display Updates: The Arduino updates the LCD in real-time to reflect any changes in temperature or settings.

Control Logic

Temperature Control: The Arduino compares the current temperature (from the thermocouple) with the target temperature set by the user. It then adjusts the power to the heating element to reach and maintain the target temperature.

PID Control (optional): For precise temperature control, a Proportional-Integral-Derivative (PID) algorithm can be implemented. This helps in maintaining a stable temperature by minimizing overshoot and oscillations.

Feedback and Alerts (Beeper and LEDs)

Beeper: Provides audio feedback for button presses, temperature reach, or any errors.

Feedback LED: Indicates the status of the soldering station, such as power on, heating, or standby mode.

Motion Sensing (Mercury Switch)

Mercury Switch: Detects the movement of the soldering iron. If no movement is detected for a predefined period, the Arduino can put the soldering station into standby mode to save energy and enhance safety.

Automatic Standby: The Arduino continuously monitors the mercury switch. Lack of movement triggers the standby mode, reducing the iron’s temperature to a safe level.

Debouncing Mechanism

Button Debouncing: Software debouncing is implemented to ensure that button presses are accurately registered, avoiding false triggers due to mechanical noise.

Workflow

Initialization: When powered on, the Arduino initializes all components, including the LCD, MAX6675 module, and input devices.

User Input: The user sets the desired temperature using the rotary encoder. The current and target temperatures are displayed on the LCD.

Temperature Monitoring: The Arduino continuously reads the temperature from the MAX6675 module.

Control Signal: Based on the temperature reading, the Arduino adjusts the power to the heating element to maintain the set temperature.

Feedback: The LCD displays real-time temperature information, and the beeper provides audio feedback. LEDs indicate operational status.

Motion Detection: The mercury switch monitors motion. Lack of movement triggers standby mode to reduce the temperature.

Memory Functions: The user can store and recall temperature settings using the dedicated buttons.

This integrated approach ensures that the soldering station operates efficiently, providing precise temperature control and user-friendly

interaction, making it a powerful tool for both hobbyists and professionals.

For Full Project :

ARDUINO BASED SMART SOLDERING STATION WITH LCD

*PCBWay community is a sharing platform. We are not responsible for any design issues and parameter issues (board thickness, surface finish, etc.) you choose.

- Comments(0)

- Likes(1)

-

Rodolfo D'Avia

Dec 11,2024

Rodolfo D'Avia

Dec 11,2024

- 0 USER VOTES

- YOUR VOTE 0.00 0.00

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

More by Rabin Poudel

More by Rabin Poudel

-

Flood Detection and warning system using LORA and Arduino

IntroductionFloods are one of the most devastating natural disasters, causing immense damage to life...

Flood Detection and warning system using LORA and Arduino

IntroductionFloods are one of the most devastating natural disasters, causing immense damage to life...

-

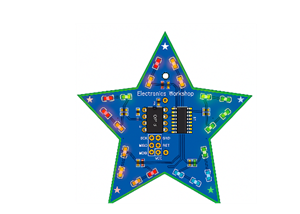

DIY LED Decoration Tiny Star PCB Project

IntroductionThe Tiny Star PCB is a small and fun DIY electronics project that is perfect for hobbyis...

DIY LED Decoration Tiny Star PCB Project

IntroductionThe Tiny Star PCB is a small and fun DIY electronics project that is perfect for hobbyis...

-

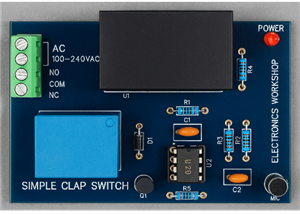

Simple and Cheap Clap Switch Circuit

IntroductionThe Simple and Cheap Clap Switch Circuit is a practical and fun DIY electronics project ...

Simple and Cheap Clap Switch Circuit

IntroductionThe Simple and Cheap Clap Switch Circuit is a practical and fun DIY electronics project ...

-

Arduino-based Mist Maker and Hand Dryer

IntroductionIn today’s world, automation and hygiene have become essential, especially in public pla...

Arduino-based Mist Maker and Hand Dryer

IntroductionIn today’s world, automation and hygiene have become essential, especially in public pla...

-

MPL3115A2 Barometric Pressure, Altitude, and Temperature Sensor

IntroductionThe MPL3115A2 is a highly accurate, low-power digital barometric pressure sensor from NX...

MPL3115A2 Barometric Pressure, Altitude, and Temperature Sensor

IntroductionThe MPL3115A2 is a highly accurate, low-power digital barometric pressure sensor from NX...

-

E-Speaker Using ESP32

IntroductionThe E-Speaker is a smart, portable, and versatile audio system built using the ESP32 mic...

E-Speaker Using ESP32

IntroductionThe E-Speaker is a smart, portable, and versatile audio system built using the ESP32 mic...

-

Heart Rate Monitor Circuit Using Photoplethysmography (PPG)

IntroductionHeart rate is a vital physiological parameter that reflects the health and fitness of an...

Heart Rate Monitor Circuit Using Photoplethysmography (PPG)

IntroductionHeart rate is a vital physiological parameter that reflects the health and fitness of an...

-

Automated Greenhouse Control System using ESP32

IntroductionAn automated greenhouse control system leverages technology to optimize plant growth con...

Automated Greenhouse Control System using ESP32

IntroductionAn automated greenhouse control system leverages technology to optimize plant growth con...

-

STD CH330N USB to Serial Converter 5V

IntroductionThe CH330N is a versatile USB-to-serial converter chip that simplifies interfacing betwe...

STD CH330N USB to Serial Converter 5V

IntroductionThe CH330N is a versatile USB-to-serial converter chip that simplifies interfacing betwe...

-

KY-032 Obstacle avoidance sensor module

IntroductionIntroduction to Obstacle Avoidance SensorsObstacle avoidance sensors are essential compo...

KY-032 Obstacle avoidance sensor module

IntroductionIntroduction to Obstacle Avoidance SensorsObstacle avoidance sensors are essential compo...

-

BC547 BASED WATER LEVEL INDICATOR

IntroductionA water level indicator using a BC547 transistor is a simple and effective electronic pr...

BC547 BASED WATER LEVEL INDICATOR

IntroductionA water level indicator using a BC547 transistor is a simple and effective electronic pr...

-

How to Design Own Arduino Wifi shield PCB

OverviewArduino wifi shield connects the Arduino with a wifi chip through the serial communication p...

How to Design Own Arduino Wifi shield PCB

OverviewArduino wifi shield connects the Arduino with a wifi chip through the serial communication p...

-

DIY Air Quality Tester

OverviewIn this project “DIY Air Quality Tester” we use Node MCU microcontroller and air quality sen...

DIY Air Quality Tester

OverviewIn this project “DIY Air Quality Tester” we use Node MCU microcontroller and air quality sen...

-

Digital Clock Using Arduino

OverviewIn this project, “Digital clock using Arduino” we will make a PCB board for digital clock an...

Digital Clock Using Arduino

OverviewIn this project, “Digital clock using Arduino” we will make a PCB board for digital clock an...

-

Bluetooth Controlled car using Arduino

OverviewA Bluetooth Controlled Car Using Arduino is a fascinating DIY project that involves building...

Bluetooth Controlled car using Arduino

OverviewA Bluetooth Controlled Car Using Arduino is a fascinating DIY project that involves building...

-

IoT-Based Automatic Street Light Controller Using ESP32

IntroductionThis system uses ESP32 modules to control street lights through a centralized IoT server...

IoT-Based Automatic Street Light Controller Using ESP32

IntroductionThis system uses ESP32 modules to control street lights through a centralized IoT server...

-

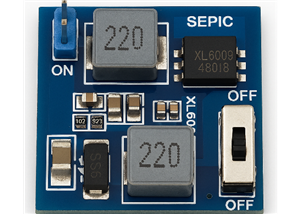

SEPIC DC-DC Converter Using the MT3608 Boost IC

IntroductionModern electronic design must prioritize effective and adaptable power management, parti...

SEPIC DC-DC Converter Using the MT3608 Boost IC

IntroductionModern electronic design must prioritize effective and adaptable power management, parti...

-

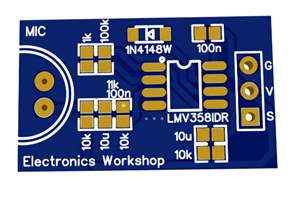

Audio Peak Detector using LMV358

IntroductionAn Audio Peak Detector is an essential circuit in audio signal processing that identifie...

Audio Peak Detector using LMV358

IntroductionAn Audio Peak Detector is an essential circuit in audio signal processing that identifie...

-

-

mammoth-3D SLM Voron Toolhead – Manual Drill & Tap Edition

140 0 0 -

-

AEL-2011 Power Supply Module

654 0 2 -

AEL-2011 50W Power Amplifier

567 0 2 -

-

-

Custom Mechanical Keyboard

769 0 0 -

Tester for Touch Screen Digitizer without using microcontroller

395 2 2 -

Audio reactive glow LED wristband/bracelet with NFC / RFID-Tags

364 0 1 -

-