Axiom: 100kW motor controller

What is it?

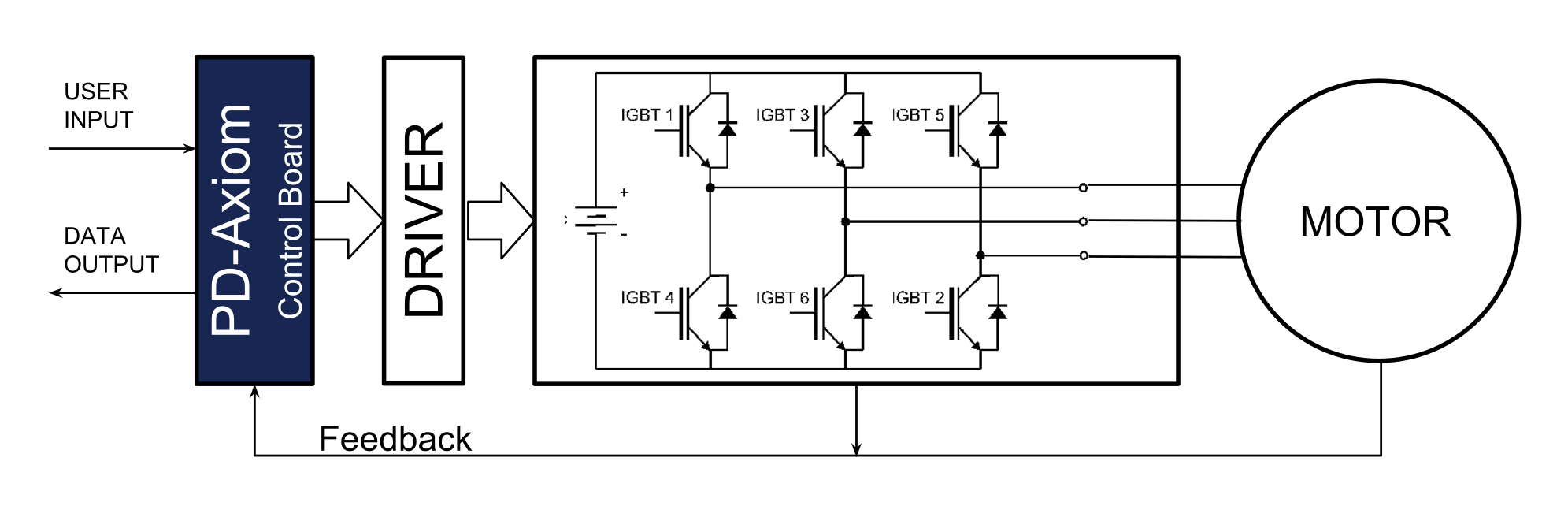

It is a 3 phase motor controller. It takes a DC voltage and generates 3 sinewaves for driving a motor, conceptually similar to those small ESC for drones and bikes. The difference is that this particular setup can safely work with a 400V battery, flowing 300Amps all year long.

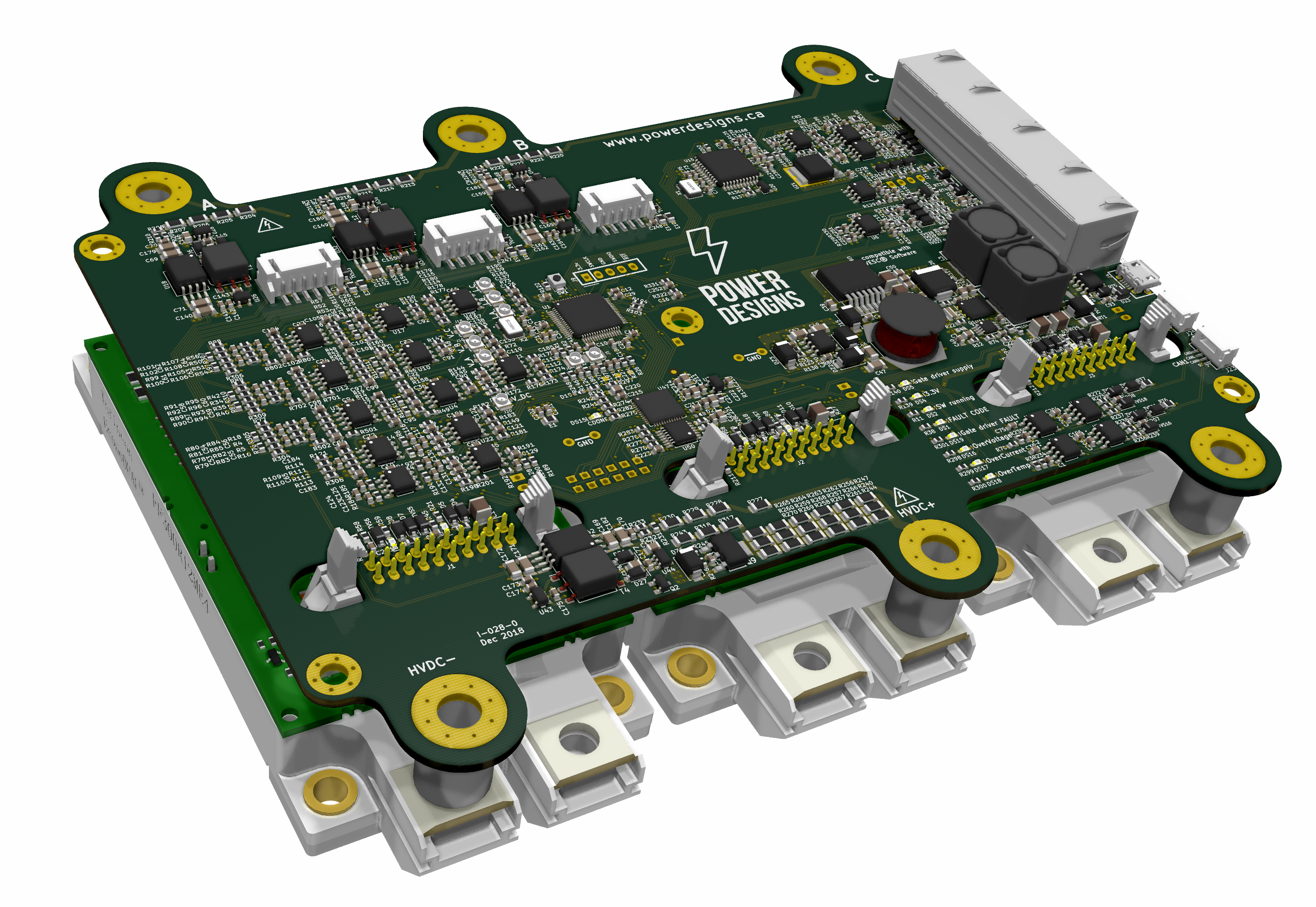

Our work has been focused in the control board, which is capable of driving way more than 400V and way more than 300A, those are defined by the powerstage ratings.

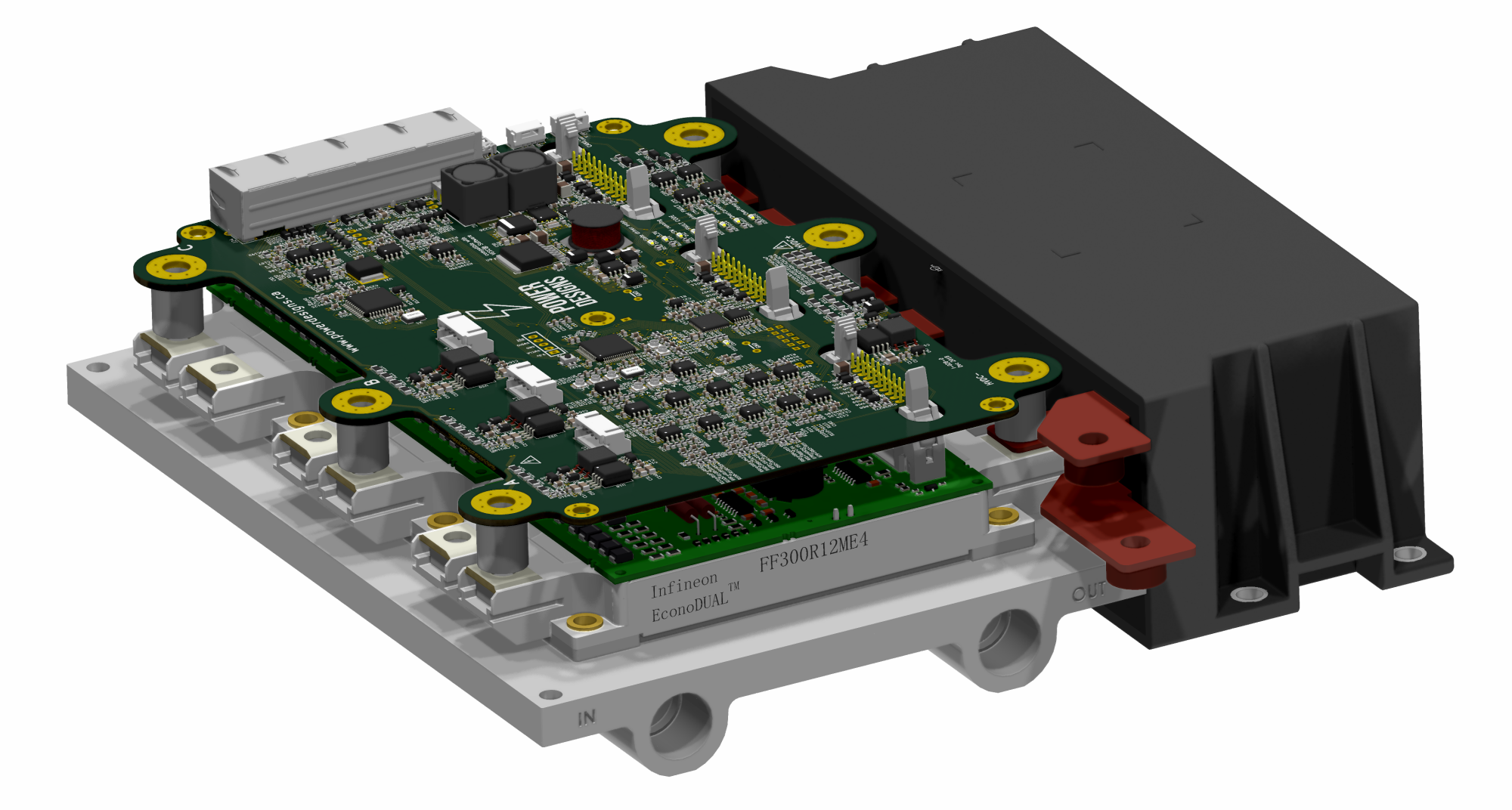

We chose EconoDual IGBT modules because its a popular package, they come in many voltage and current levels (from 600V to 1700V, and from 100A to 1000A), from many brands, in both IGBT and SiC technology and with available off the shelf gate drivers matched for them.

Why?

Because we want to be part of the boldest, most spectacular builds, there is no other open platform capable of driving a 100kW-class motor. All you can get are proprietary controllers with high markups and no way to tweak them to your needs, and most importantly, you don't get to see the inner workings to evaluate if the quality is up to your standards, both in software and hardware.

The new wave of EV companies have been tied to proprietary motor drives, we provide our customers with a chance to deeply integrate the motor drive into their systems, offering a unique chance of verticalization within their product. This saves costs and improves the quality and integration of their vehicles.

Opening up Axiom also showcases the quality of our work and makes our team a desirable contractor, there are not many people in the world with the set of skills and knowledge to produce a high performance drive unit.

Axiom is also made possible thanks to the VESC? base platform growing steadily to the point we can take it for the first time to the next level, from a hobby tool to a full EV-capable piece of technology.

Who is using an Axiom?

Since we went public this year several individuals and engineering teams around the world signed up for ordering an Axiom. We are currently on a beta testing stage, only picking the most equipped engineering teams capable of providing us with valuable feedback to make sure we deliver a solid product. Well over a hundred direct requests were handled, here are some of the teams with an Axiom controller under test:

We are covering 5 continents!

Roughly half of the applications are for traction vehicles (cars, bikes, racing), others are for aircraft, and some are pure R&D departments.

Contact us if you want to apply to be a beta tester!

What can you do with an Axiom?

Pretty much anything involving a powerful 3 phase motor.

- Electric Vehicle conversions

- EV racing

- Mining

- OEM EV like bikes and ATV

- Subsea ROVs

- Aircraft systems (*)

- Glider launchers (*)

- Wind generators

- R&D

Did you imagine this could be used to launch a glider? We neither! That list mostly comes from meetings with our customers.

Why do they choose us?

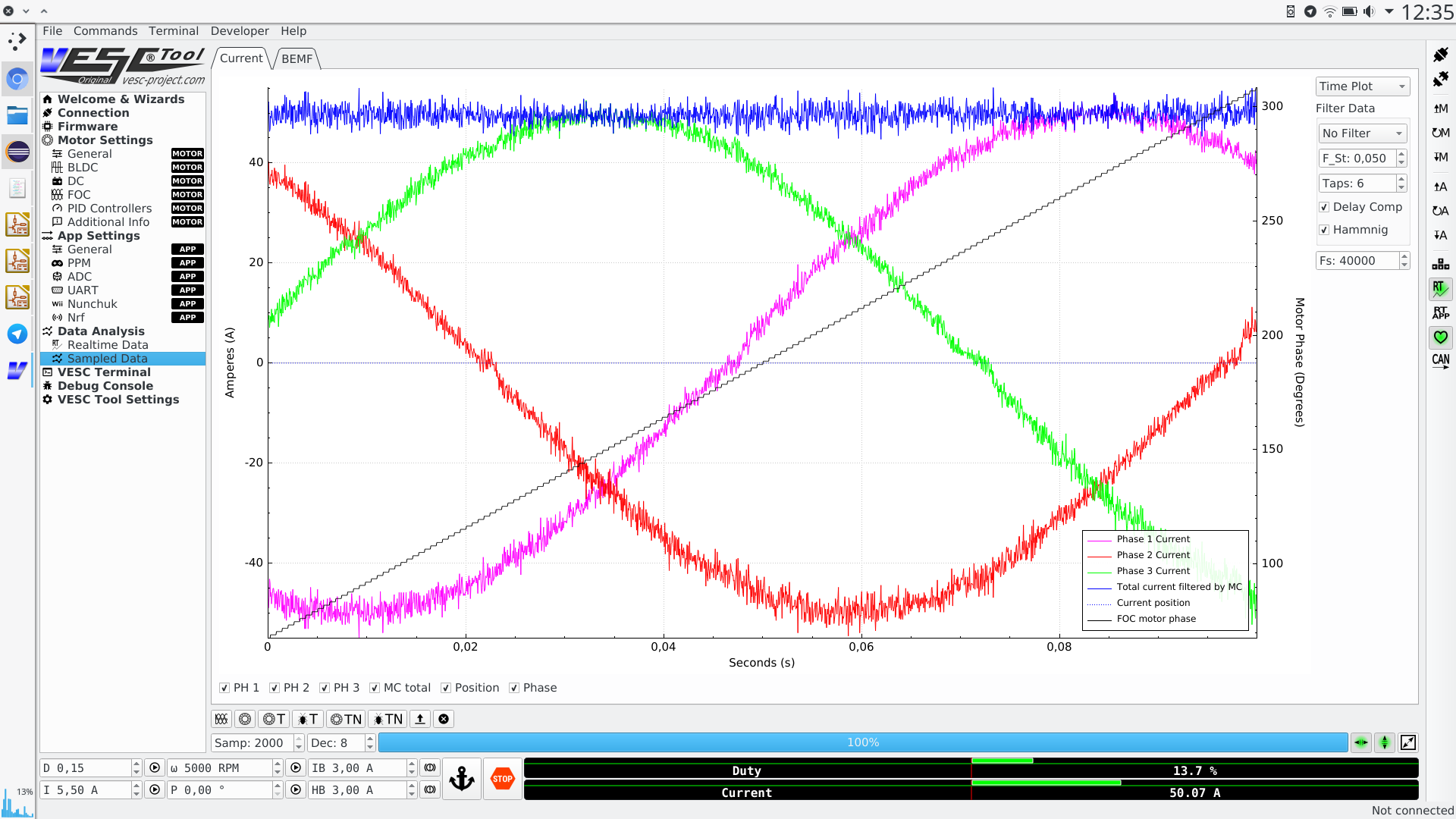

Because the performance and the user experience of a VESC? system are simply top notch. The user needs an interface to configure the motor parameters, and it will be the main tool for debugging problems and getting to know the machine. Hats off to Benjamin's VESC Tool:

With software and firmware in place, a high power application will need some very particular hardware:

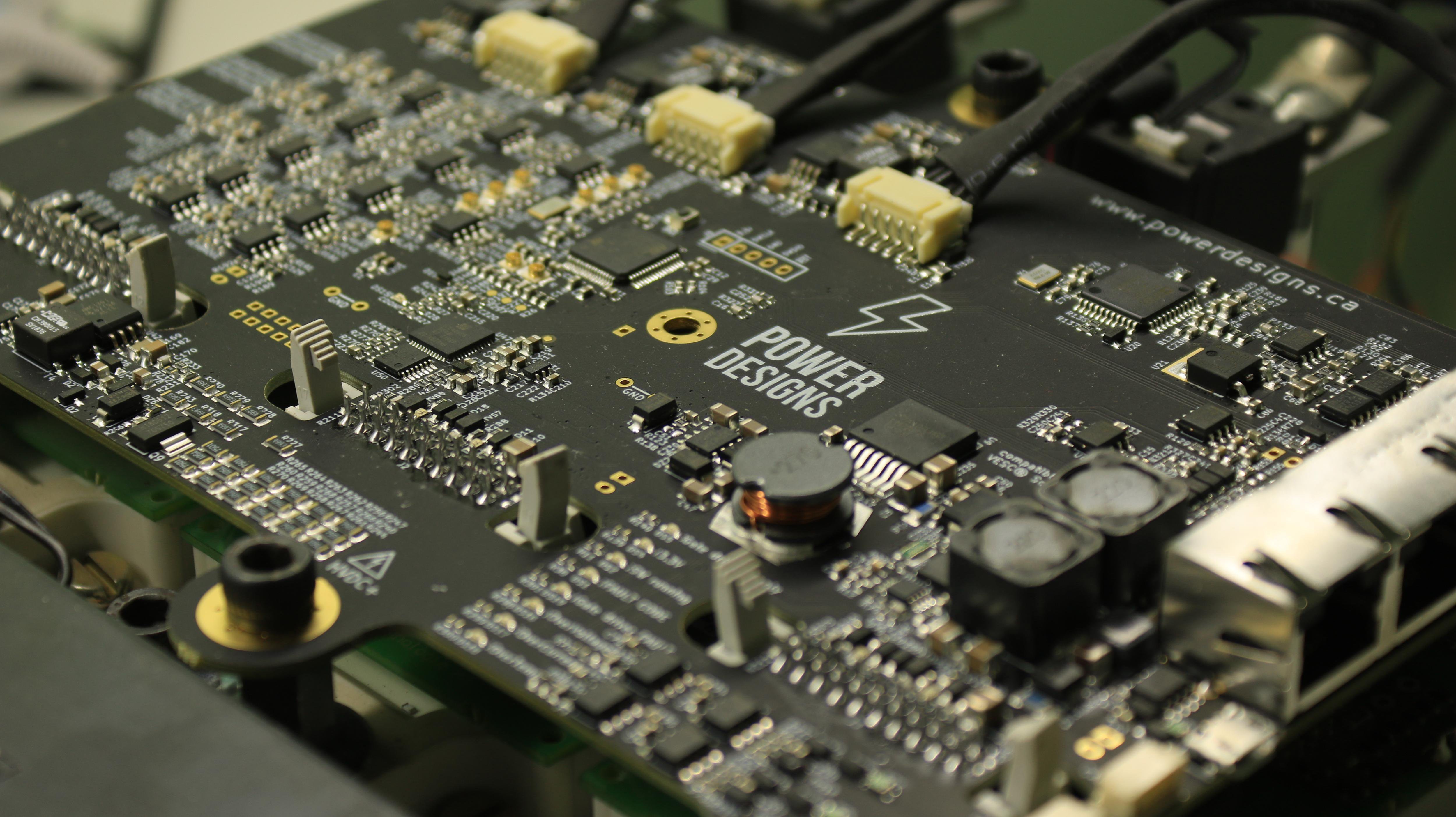

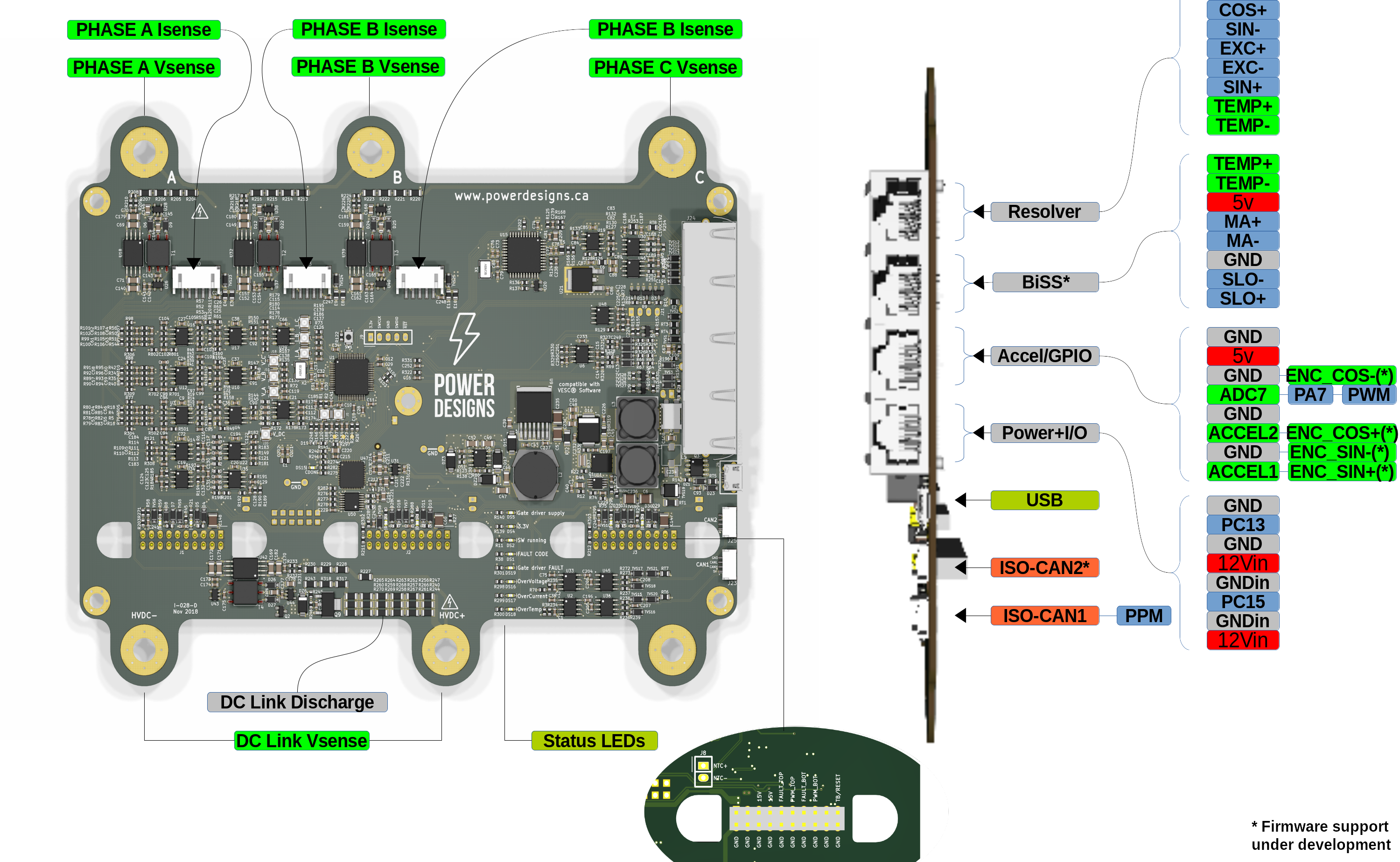

Here is our take at this:

- Mechanically matched to EconoDual/17mm IGBT modules. More compact, fewer assembly steps, less wiring and crimping, no adapter parts.

- Isolated HVDC and phase voltage monitoring integrated on board, direct connection to the IGBTs for cleaner signals and faster assembly.

- DC Link Capacitor discharge resistor on board. Safety requirement, discharges it when board is not powered.

- RF connectors to measure analog signals. This provides simulation-like signal quality, extremely good for development.

- Individual IGBT fault monitoring. You can tell which IGBT faulted.

- Individual fault leds for overvoltage, overcurrent and overtemperature.

- Individual IGBT temperature monitoring.

- A Lattice iCE40 FPGA, using an open source toolchain for sinthesis and HDL development.

- The FPGA is continuously monitoring all fault inputs. If any fault is asserted, all PWM activity is shut down.

- FPGA supervises the PWM generated by the MCU. Shuts down PWM if a shoot-through command is detected.

- We are implementing this awesome motor control trick in the FPGA

- RJ45 ports. These are not ethernet, they provide a shielded, twisted pair wiring in a standard off the shelf fashion.

- Dual analog Accelerator inputs.

- Dual isolated CANbus interfaces (firmware no there yet for the 2nd interface).

- Resolver support.

- BiSS absolute encoder support (firmware under dev).

- Sin/Cos encoder support.

- Supplies a regulated 15Vdc to the gate drivers, and monitors that voltage.

- 2 DAC outputs with RF connectors to peek inside the control algorithms.

- 2 Open drain outputs for driving small loads or relays, for a pump for example.

- More fuses, more TVS, more EMI filtering.

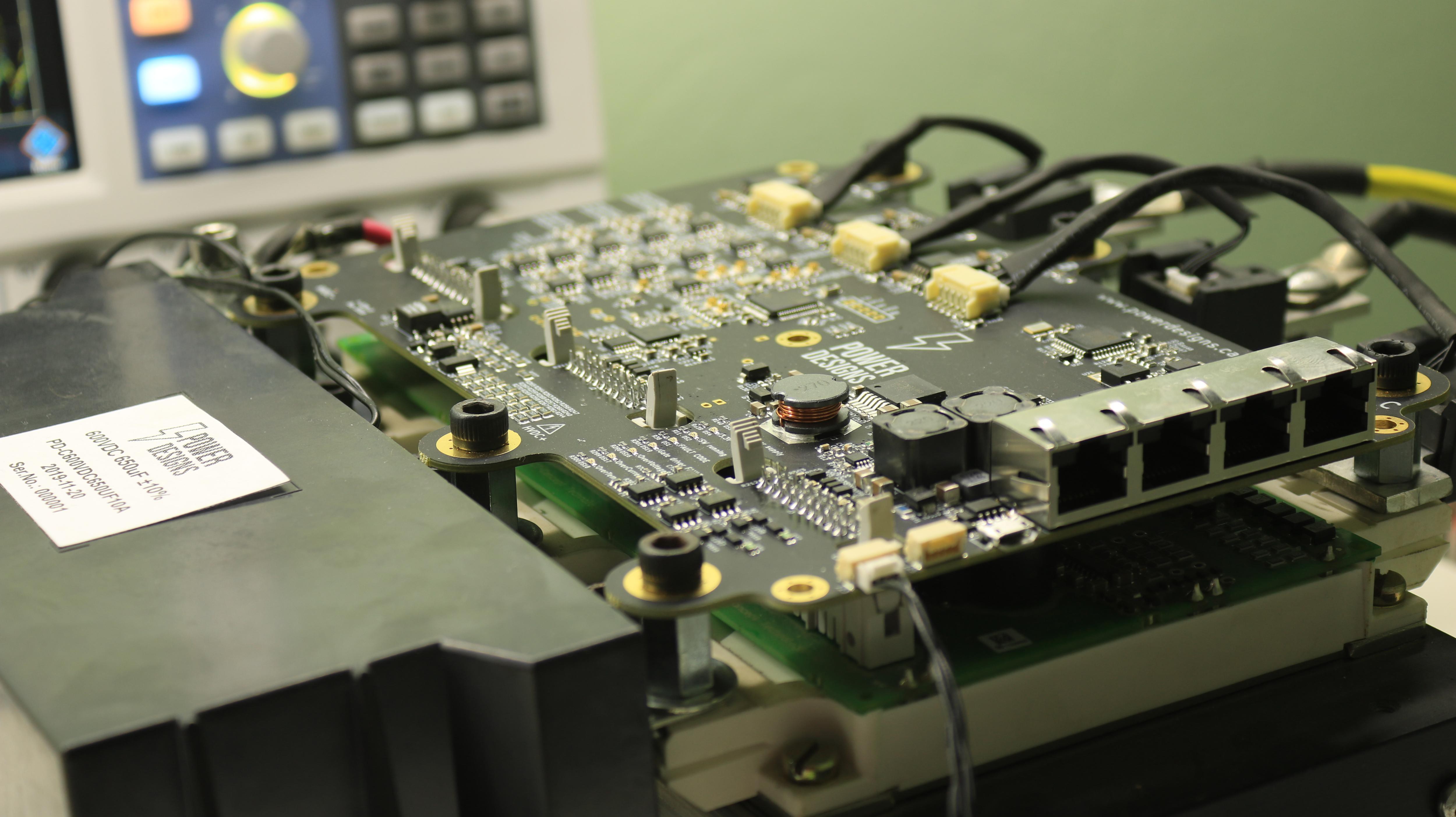

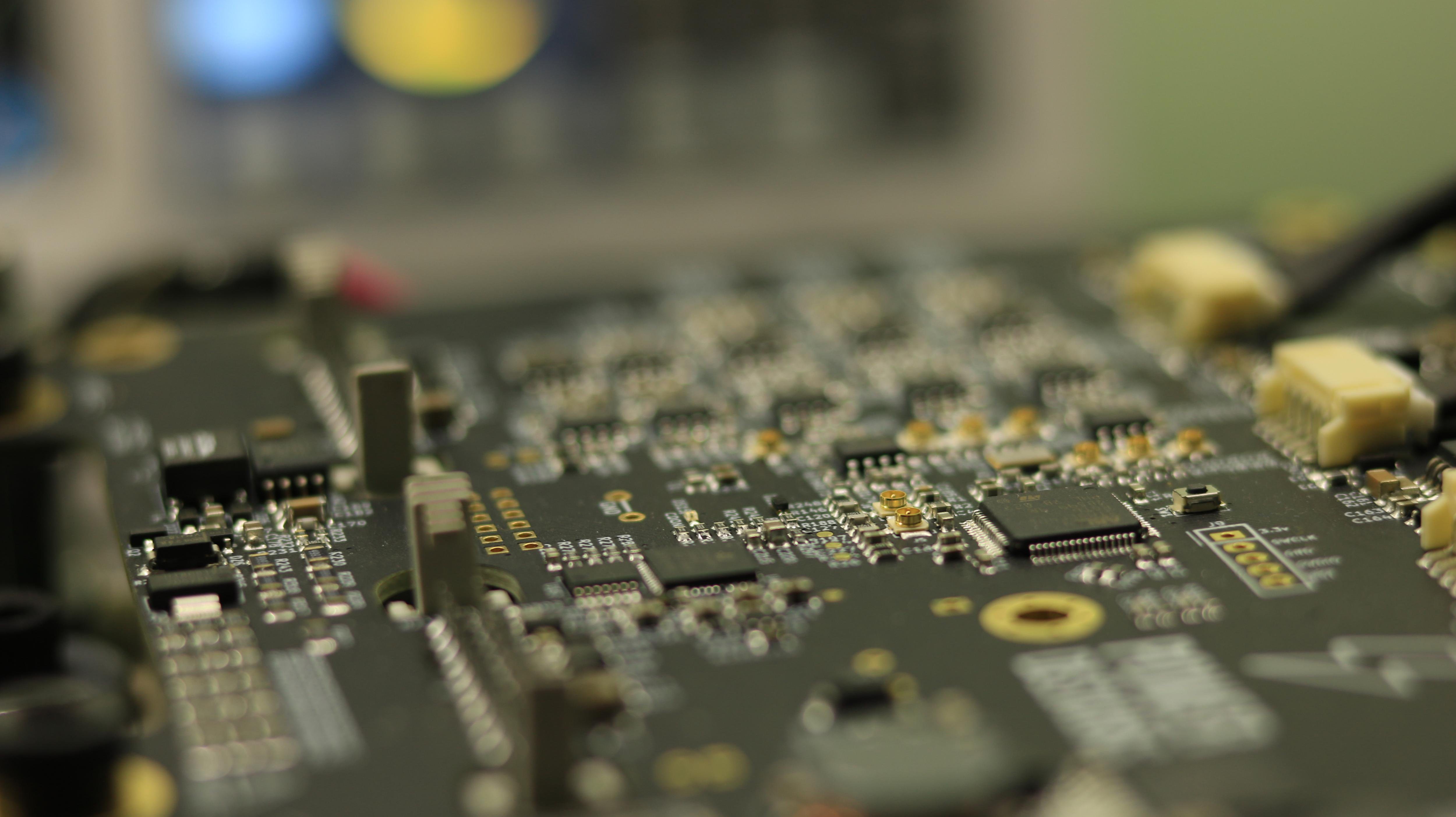

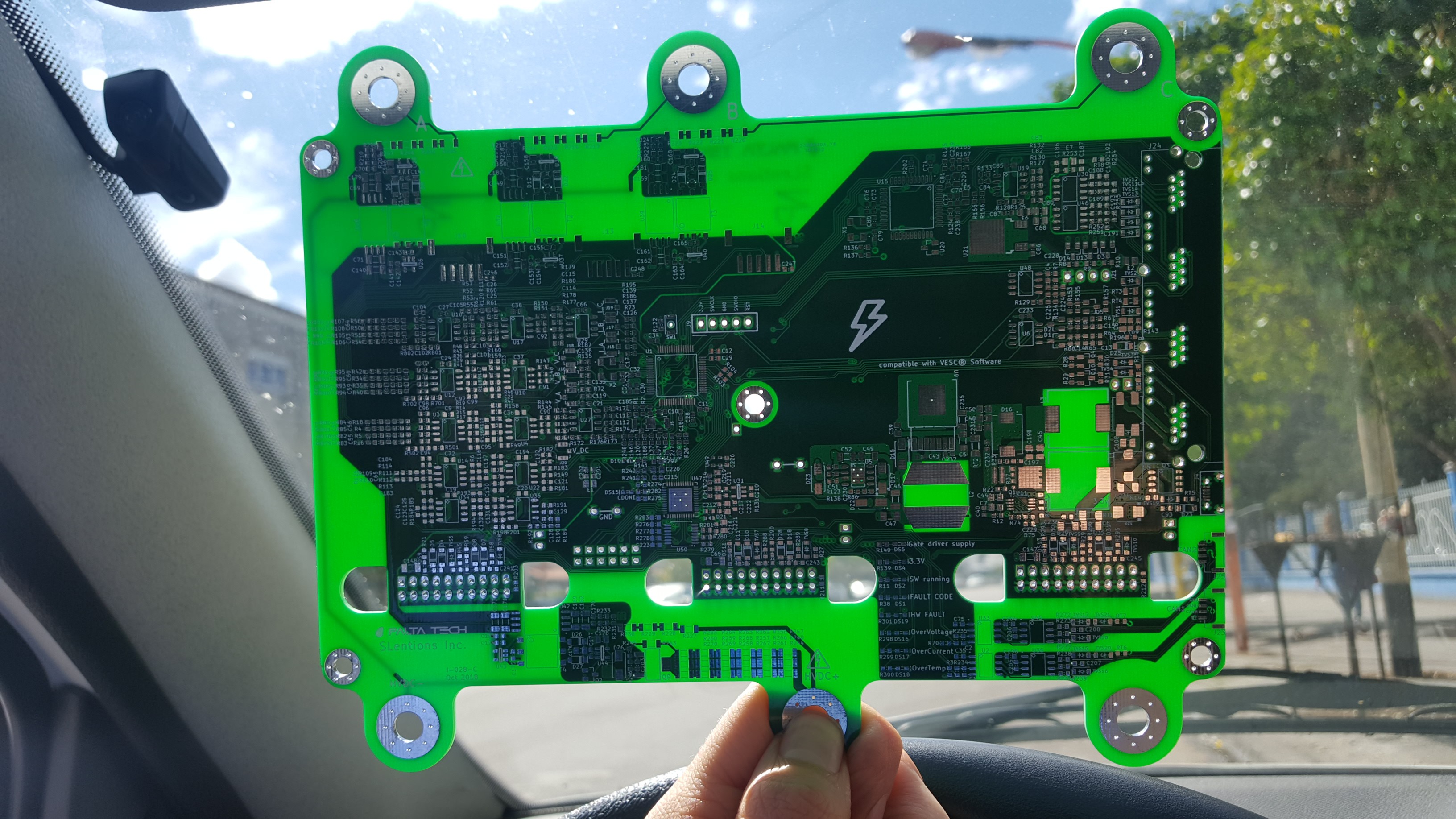

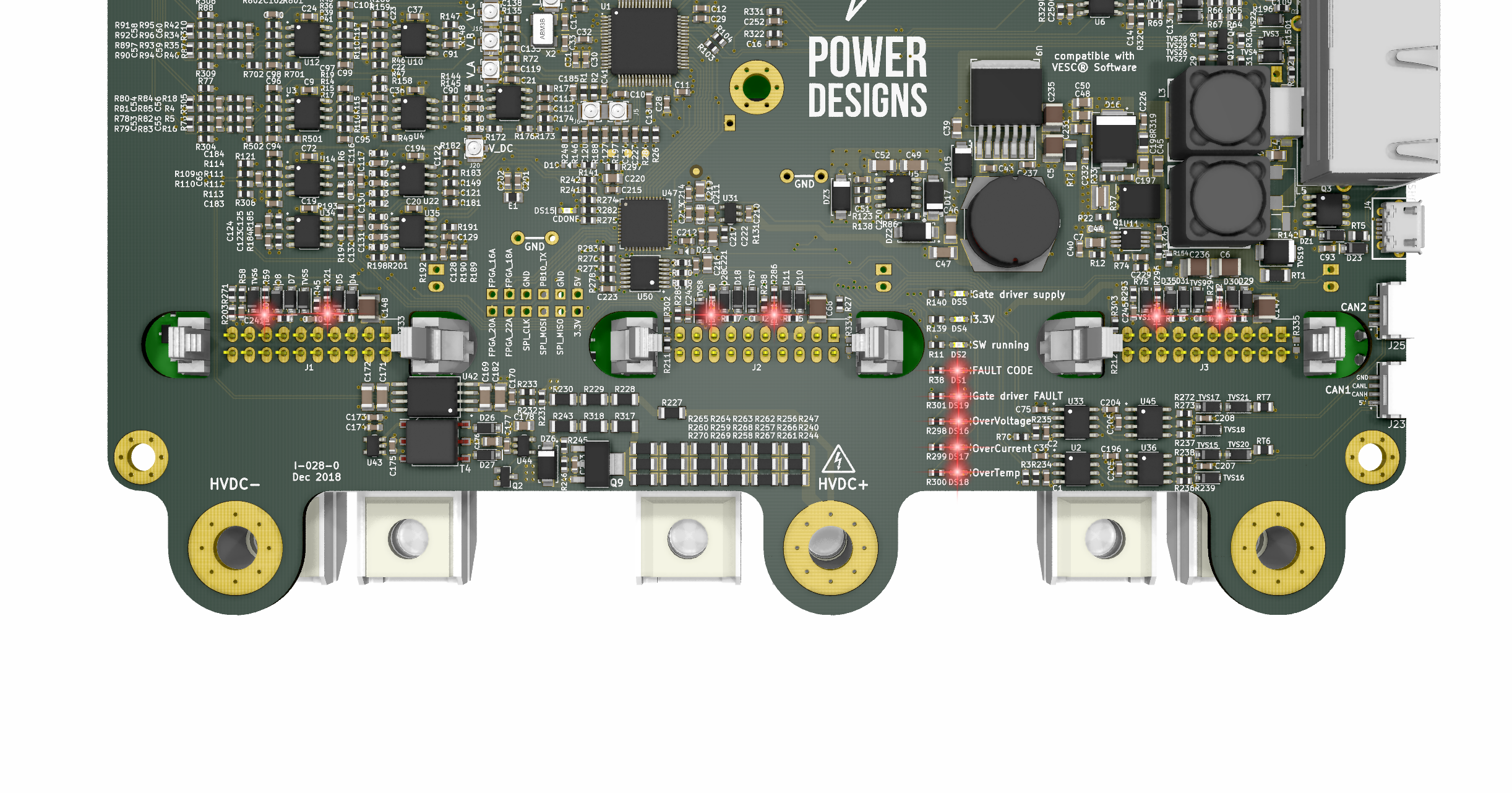

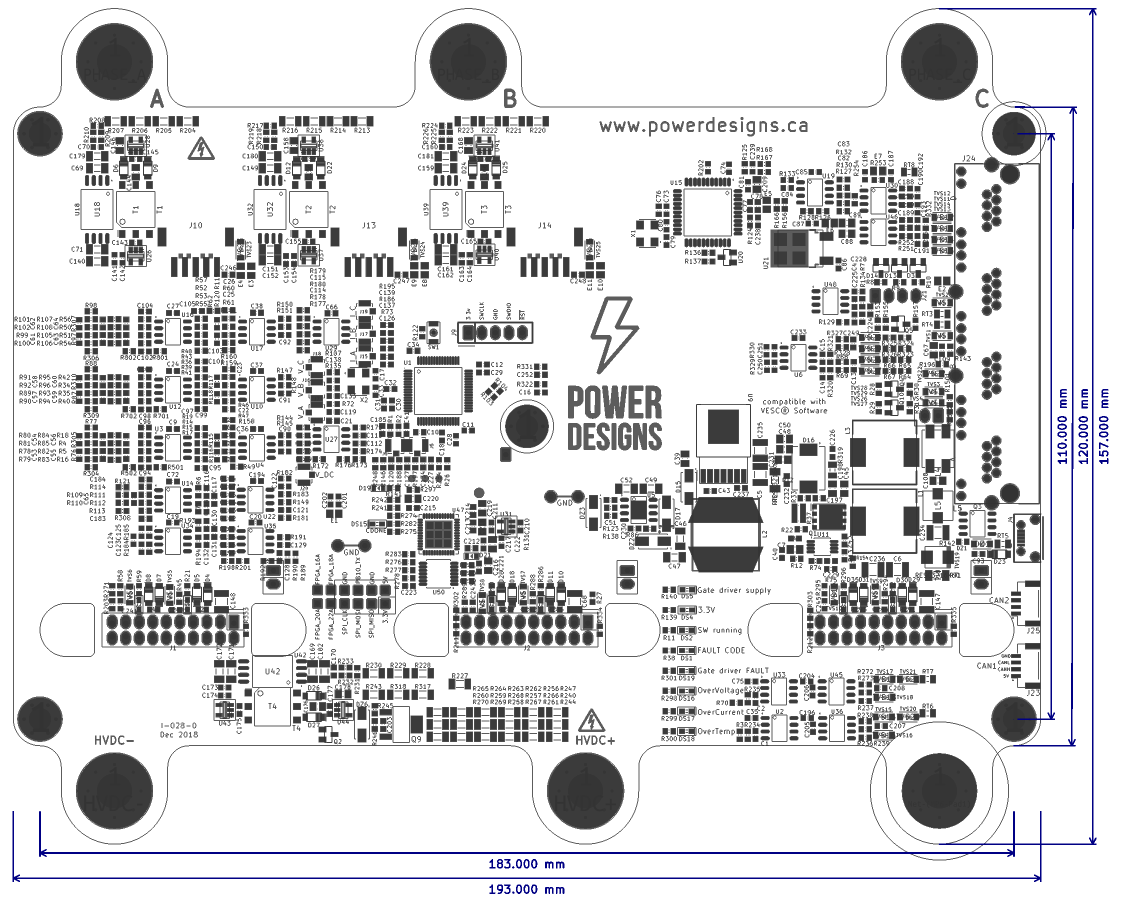

Here are some high-res images for reference:

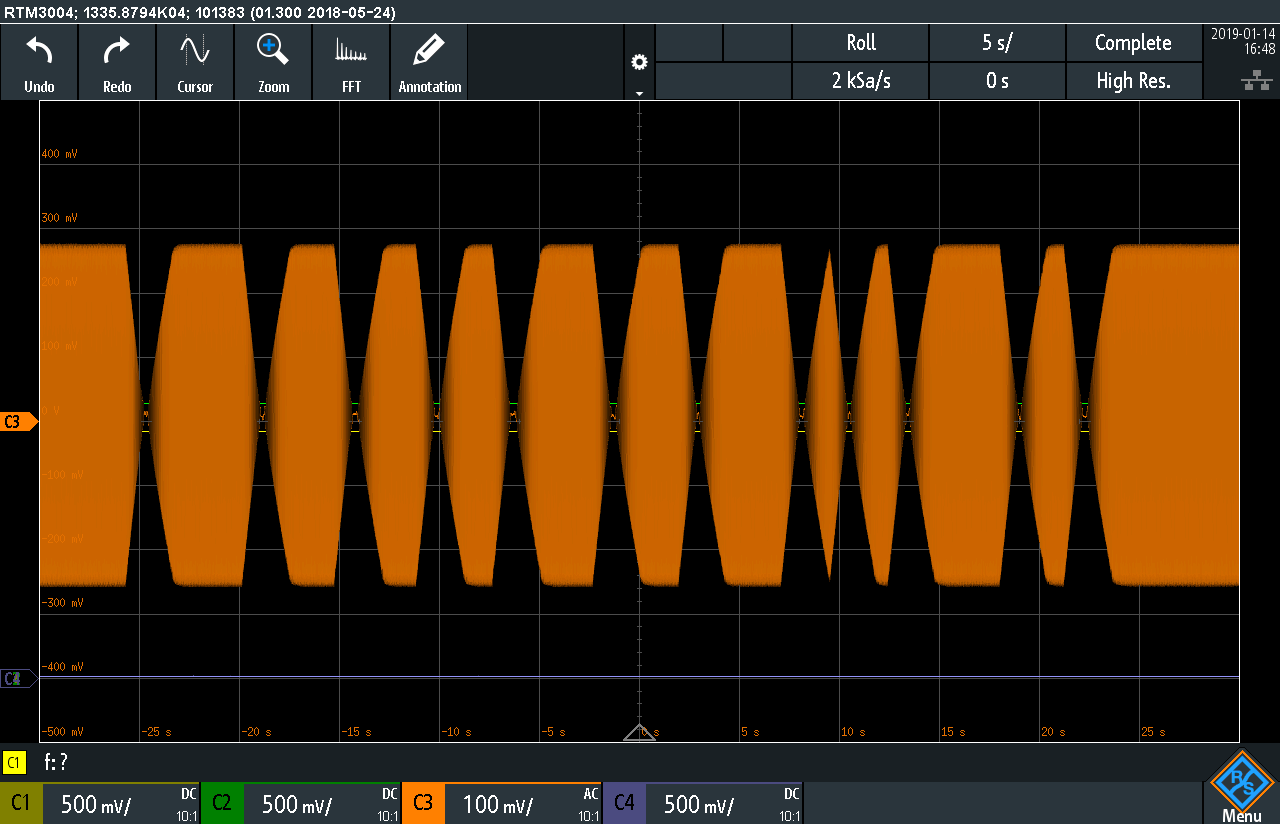

Poking your critical analog signals with RF connectors should be mandatory in school:

An old prototype that can show the isolation cleareances. With newer boards you don't see through the thick soldermask

A sensorless full speed reversal with an IGBT-based powerstage: (yellow trace is the observer phase being output to a DAC channel). You don't get to see this often

Unless it is an Axiom! Many full speed reversals:

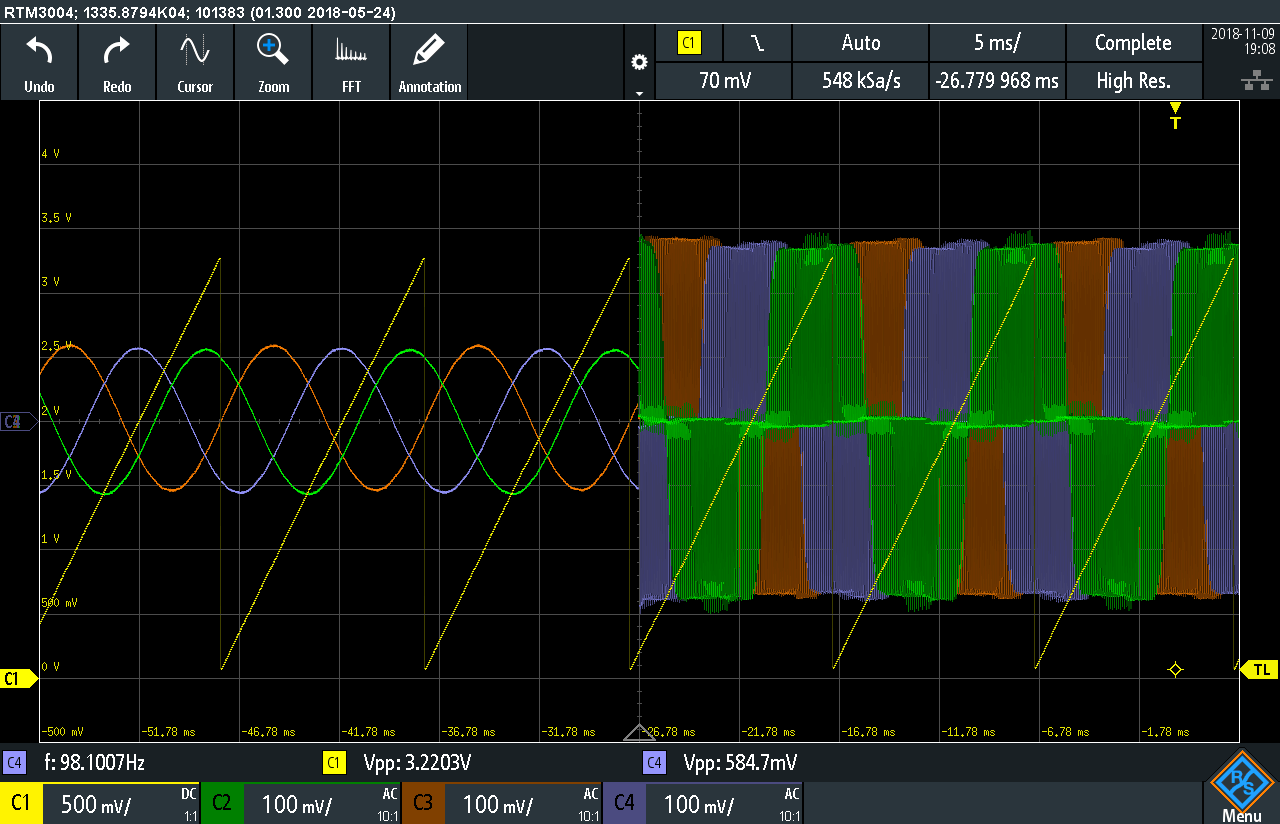

This is an exercise on the signal quality of the the board, in practice we strongly suggest to use absolute encoders on high power builds.

Crystal clear signals measured right at the ADC pins, and motor angle sent over the DAC to the scope. Note how motor angle is perfectly tracked in the undriven->driven transition.

Clear fault reporting

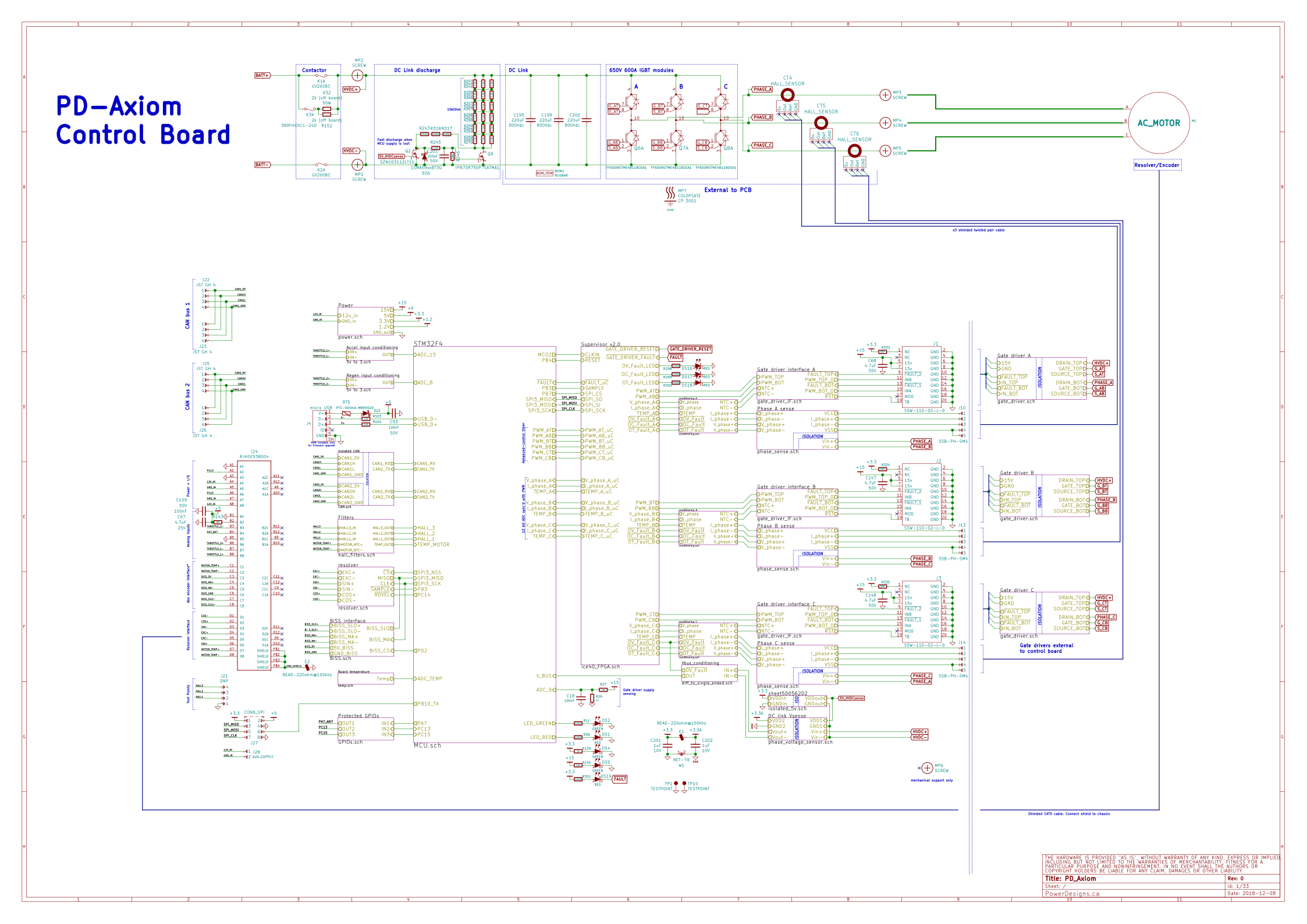

Schematic top level:

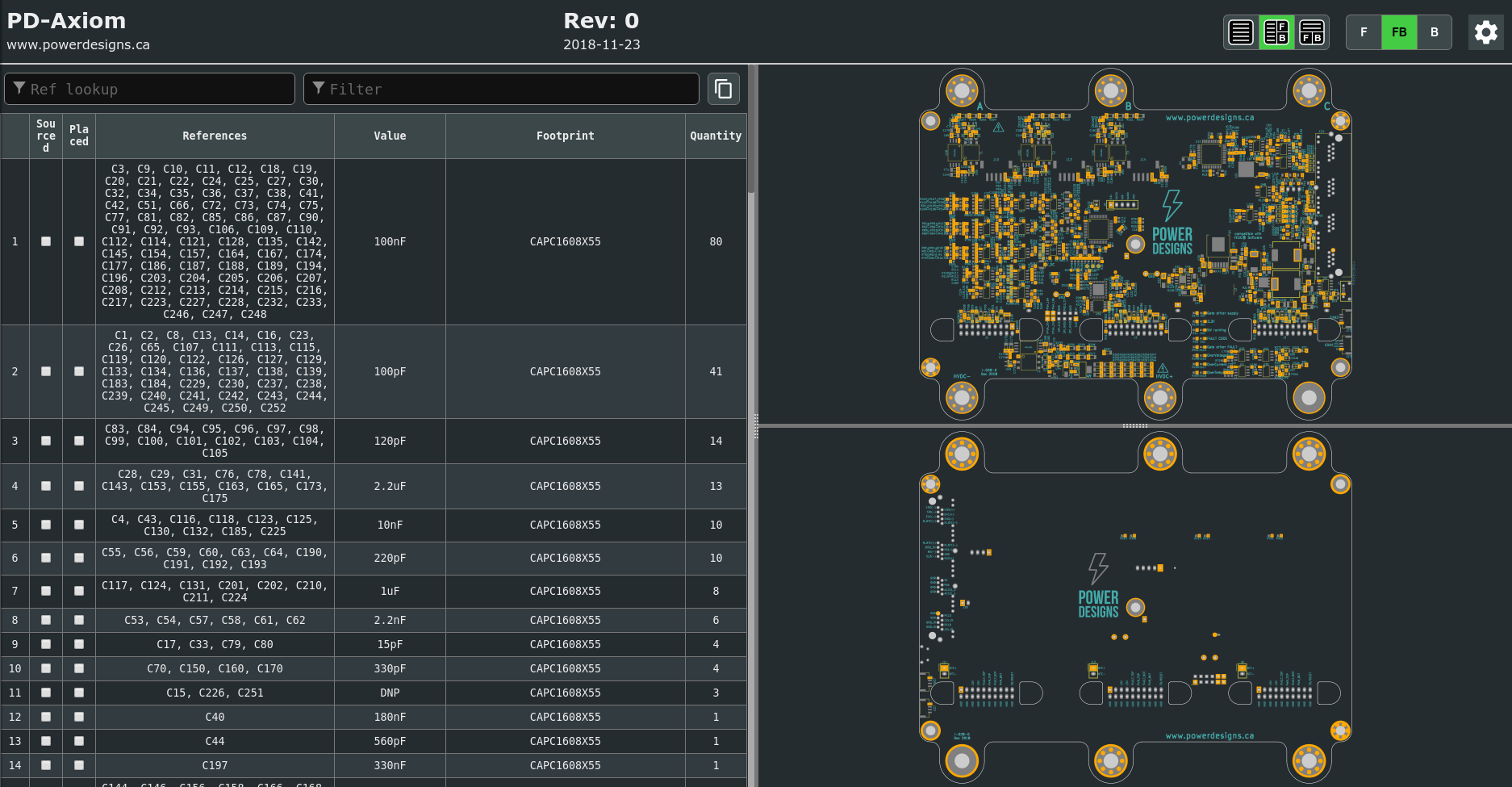

Click on the link for an interactive BOM viewer: http://paltatech.com/files/ibom.html

More data, board datasheet and images are be available at www.powerdesigns.ca, as well as schematic and other design files. The build in the pictures is designed for 400V 300Amp continuous operation.

How it works?

It takes your battery voltage (High Voltage DC) and using PWM creates 3 sinewaves spread 120° for driving a motor. Actually, it uses Space Vector Modulation (SVM), which reduces the amount of switching required, and hence the switching losses.

Despite VESC supports driving motors in both trapezoidal and Field Oriented Control control modes, our boards only work in FOC. Its just better suited for the application.

FOC is about aligning your sinewaves with the actual field inside the motor, and controlling the machine with a vector signal composed on a torque-generating current in quadrature with the flux (Iq), and a flux-generating current (Id). There are lots of good resources about this topic, and you can see the actual lines of code performing the transformations here.

See the logs for more details!

The BIGGEST news about this project is the formal presentation of the team that made it possible. Forum legends HighHopes and Arlo1 are deeply involved in the design, we have been working together on getting this control board out, and we founded www.powerdesigns.ca to centralize all the contract work we have been doing together.

So what does this means? Arlo1 provides the field experience with his awesome, record-setting builds and tooling while HighHopes provides deep insight, his power systems knowledge and hard math to every design decision, while Maxi and I do what we do best, engineering, CAD, firmware and manufacturing. And remember this is standing on years of Benjamin Vedder's firmware development, to which we are already collaborators.

PowerDesigns should provide the assembled boards to anyone interested. We can offer bare PCBs on demand but the risk is so high and I didn't see a successful build when people have to assemble the boards, so its better if we take care of the assembly. Its even much better if we provide the complete motor controller, we are working on providing that solution.

Maxi (co-founder engineer at paltatech) and me switched gears some months ago to firmware developing and testing when the hardware design was settled, meanwhile some alpha users start putting some miles on this, not many miles actually, we are still craving for testers and we don't claim it comes without bugs. All the code we provide for these high power applications is carefully crafted for direct integration into the VESC codebase so it stays public and well maintained.

Hardware-wise, we have math for finely setting our trip points, which we can easy tune at will by changing resistors, and the FPGA is a very powerful addition for co-processing and safety functions. We went as far as designing our own DC Link with an OEM, shown in the pictures and still under testing.

Its quite a compact and tidy unit.

This is an awesome platform for research and for high power builds, I don't know of any controller at this power level, with this quality and attention to detail while open to the user to modify the firmware at will.

We have been going on for a long way without external feedback, so I'm eager to hear what you guys think. Axiom is not meant to be a cheap controller, its meant to drive very expensive and dangerous equipment, so it must be a safe and solid piece of hardware.

(*) Axiom has not yet been qualified for aircraft/aerospace applications.

Axiom: 100kW motor controller

Raspberry Pi 5 7 Inch Touch Screen IPS 1024x600 HD LCD HDMI-compatible Display for RPI 4B 3B+ OPI 5 AIDA64 PC Secondary Screen(Without Speaker)

BUY NOW

ESP32-S3 4.3inch Capacitive Touch Display Development Board, 800×480, 5-point Touch, 32-bit LX7 Dual-core Processor

BUY NOW

Raspberry Pi 5 7 Inch Touch Screen IPS 1024x600 HD LCD HDMI-compatible Display for RPI 4B 3B+ OPI 5 AIDA64 PC Secondary Screen(Without Speaker)

BUY NOW- Comments(10)

- Likes(32)

-

Engineer

Jan 31,2025

Engineer

Jan 31,2025

-

Ev Pro World

Jan 15,2025

Ev Pro World

Jan 15,2025

-

Engineer

Nov 24,2024

Engineer

Nov 24,2024

-

Engineer

Sep 17,2024

Engineer

Sep 17,2024

-

Engineer

Apr 22,2024

Engineer

Apr 22,2024

-

sam h

Oct 24,2023

sam h

Oct 24,2023

-

Engineer

Aug 17,2023

Engineer

Aug 17,2023

-

László Barna

May 14,2023

László Barna

May 14,2023

-

RafaRocha

Feb 23,2023

RafaRocha

Feb 23,2023

-

Scott Cook

Dec 05,2022

Scott Cook

Dec 05,2022

-

David Westwood

Nov 09,2022

David Westwood

Nov 09,2022

-

Sergio Oliveira

Aug 18,2022

Sergio Oliveira

Aug 18,2022

-

Engineer

Jun 13,2022

Engineer

Jun 13,2022

-

Mohamed Tawfik

Jan 25,2022

Mohamed Tawfik

Jan 25,2022

-

Fedor Zagumennov

Jan 06,2021

Fedor Zagumennov

Jan 06,2021

-

Engineer

Jan 04,2021

Engineer

Jan 04,2021

-

Engineer

Nov 08,2020

Engineer

Nov 08,2020

-

Engineer

Jul 22,2020

Engineer

Jul 22,2020

-

Sam Catchpole-Smith

Jun 27,2020

Sam Catchpole-Smith

Jun 27,2020

-

Jethro Karsters

Jun 15,2020

Jethro Karsters

Jun 15,2020

-

Seyran BOYACI

Jun 15,2020

Seyran BOYACI

Jun 15,2020

-

Hadjaidji Nour

Jun 12,2020

Hadjaidji Nour

Jun 12,2020

-

Alexandre Netchaieff

May 25,2020

Alexandre Netchaieff

May 25,2020

-

Kevin Yang

May 21,2020

Kevin Yang

May 21,2020

-

Engineer

May 15,2020

Engineer

May 15,2020

-

Salvatore Raccardi

Apr 27,2020

Salvatore Raccardi

Apr 27,2020

-

Duncan Hames

Apr 06,2020

Duncan Hames

Apr 06,2020

-

Marin Mikael

Mar 27,2020

Marin Mikael

Mar 27,2020

-

Engineer

Mar 25,2020

Engineer

Mar 25,2020

-

michelegazzarri

Mar 20,2020

michelegazzarri

Mar 20,2020

-

marcos

Feb 25,2020

marcos

Feb 25,2020

-

garpunchik

Feb 24,2020

garpunchik

Feb 24,2020

- 26 USER VOTES

- YOUR VOTE 0.00 0.00

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

10design

-

10usability

-

10creativity

-

10content

-

10design

-

10usability

-

10creativity

-

10content

-

10design

-

10usability

-

10creativity

-

10content

-

2design

-

3usability

-

4creativity

-

5content

-

10design

-

1usability

-

8creativity

-

10content

-

1design

-

2usability

-

2creativity

-

2content

-

5design

-

8usability

-

9creativity

-

7content

-

10design

-

10usability

-

10creativity

-

10content

-

10design

-

10usability

-

10creativity

-

10content

-

10design

-

10usability

-

10creativity

-

10content

-

1design

-

2usability

-

3creativity

-

5content

-

10design

-

10usability

-

10creativity

-

10content

-

10design

-

10usability

-

10creativity

-

10content

-

10design

-

10usability

-

10creativity

-

7content

-

10design

-

10usability

-

10creativity

-

10content

-

10design

-

10usability

-

10creativity

-

10content

-

10design

-

8usability

-

9creativity

-

10content

-

10design

-

10usability

-

8creativity

-

10content

-

10design

-

10usability

-

10creativity

-

10content

-

10design

-

9usability

-

10creativity

-

10content

-

9design

-

8usability

-

9creativity

-

9content

-

10design

-

8usability

-

10creativity

-

8content

-

9design

-

10usability

-

8creativity

-

9content

-

1design

-

2usability

-

3creativity

-

10content

-

9design

-

9usability

-

8creativity

-

9content

-

2design

-

3usability

-

4creativity

-

10content

More by marcos

More by marcos

-

-

Commodore 64 1541-II 1581 Floppy Disk Drive C64 Power Supply Unit USB-C 5V 12V DIN connector 5.25

287 1 3 -

Easy to print simple stacking organizer with drawers

106 0 0 -

-

-

-

-

-

-

Modifying a Hotplate to a Reflow Solder Station

1198 1 6 -

MPL3115A2 Barometric Pressure, Altitude, and Temperature Sensor

682 0 1 -

that's right. working hard every day. please join our mailing list if you'd like to stay updated on what we do. we've been working on bi-directional chargers too, lots of fun power electronic stuff happening! http://www.powerdesigns.ca/newsletter/