Aditya ATOM

INDIA • + Follow

Edit Project

Components

|

|

Mini Breadboard |

x 2 | |

|

|

Arduino Nano |

x 1 | |

|

|

MPU6050 |

x 1 | |

|

|

L293d driver IC |

x 1 | |

|

|

N20 gear motor |

x 2 | |

|

|

N20 motor brackets |

x 2 | |

|

|

N20 motor wheels |

x 1 |

Tools, APP Software Used etc.

|

arduino IDEArduino

|

|

|

Autodesk Fusion 360Autodesk

|

Description

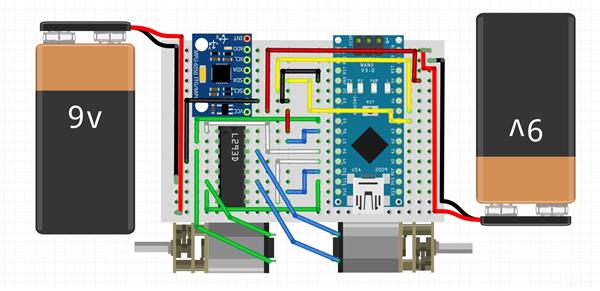

The Breadboarded Self Balancing Robot

A self Balancing Robot where electronic modules and components are connected to each other on a breadboard.

How easy it is to assemble:

- 3D print the chassis

- mount the brackets on the chassis

- insert the motor

- connect all modules and components together on breadboard using jumpers

- insert the breadboard and batteries on the chassis

Making the Robot to balance:

- install the drivers for arduino

- install libraries for MPU6050 and PID controller

- Upload the code in arduino

Power the robot using 9V batteries and see it in action

More build details here.

All the project files are on Github.

Code

Arduino Code

C/C++

//Installing necessary libraries

#include <Wire.h>

#include <I2Cdev.h>

#include <MPU6050.h>

#include <PID_v1.h>

//defined macros

#define LeftMotorDir 11

#define LeftMotorPower 5

#define RightMotorDir 10

#define RightMotorPower 6

#define LeftMotorEnable 8

#define RightMotorEnable 9

//the angle where the robot is stable

double Setpoint = -0.75;

double Input, Output;

//PID controllers

double Kp = 4.6;

double Kd = 0.04;

double Ki = 1;

//required variables

int accY, accZ, gyroX;

float accAngle = 0, gyroAngle = 0, previousAngle = 0;

float gyroRate = 0;

int val = 0;

//instance of class PID

PID myPID(&Input, &Output, &Setpoint, Kp, Ki, Kd, DIRECT);

//instance of class MPU6050

MPU6050 mpu;

/*.............................SETUP.................................*/

/*...................................................................*/

void setup() {

//initializing MPU6050

mpu.initialize();

//setting the pinmodes

pinMode(LeftMotorEnable, OUTPUT);

pinMode(LeftMotorDir, OUTPUT);

pinMode(LeftMotorPower, OUTPUT);

pinMode(RightMotorEnable, OUTPUT);

pinMode(RightMotorDir, OUTPUT);

pinMode(RightMotorPower, OUTPUT);

//making enable pin high

digitalWrite(LeftMotorEnable, HIGH);

digitalWrite(RightMotorEnable, HIGH);

//setting PID parameters

myPID.SetMode(AUTOMATIC);

myPID.SetOutputLimits(-255, 255); // may change (50,255);

myPID.SetSampleTime(5); //how often pid is evaluated in millisec

myPID.SetControllerDirection(REVERSE);

//initialize the timer

initTimer2();

}

/*..............................LOOP.................................*/

/*...................................................................*/

void loop() {

accZ = mpu.getAccelerationZ();

accY = mpu.getAccelerationY();

gyroX = mpu.getRotationX();

accAngle = atan2(accZ, -accY) * RAD_TO_DEG;

gyroRate = gyroX / 131;

Input = 0.97 * (previousAngle + gyroAngle) + 0.03 * (accAngle);

previousAngle = Input;

myPID.Compute();

if (Output > Setpoint)

{

digitalWrite(LeftMotorDir, LOW);

digitalWrite(RightMotorDir, LOW);

val = map(Output, 0, 255, 18, 255);

analogWrite(LeftMotorPower, val);

analogWrite(RightMotorPower, val);

}

if (Output < Setpoint)

{

digitalWrite(LeftMotorDir, HIGH);

digitalWrite(RightMotorDir, HIGH);

val = map(Output, -255, 0, 0, 237);

analogWrite(LeftMotorPower, val);

analogWrite(RightMotorPower, val);

}

}

/*................... ........ISR_TIMER2.............................*/

/*...................................................................*/

ISR(TIMER2_COMPA_vect)

{

gyroAngle = (float)gyroRate * 0.001;

}

/*...........................iniTimer2...............................*/

/*...................................................................*/

void initTimer2()

{

//reset timer2 control register A

TCCR2A = 0;

//set CTC mode

TCCR2A |= (1 << WGM21);

TCCR2A &= ~(1 << WGM20);

TCCR2B &= ~(1 << WGM22);

//prescaler of 128

TCCR2B &= ~(1 << CS21);

TCCR2B |= ((1 << CS22) | (1 << CS20));

//reset counter

TCNT2 = 0;

//set compare register

OCR2A = 125;

//enable timer1 compare match interrupt

TIMSK2 |= (1 << OCIE2A);

//enable global interrupt

sei();

}

Schematic and Layout

CAD-Custom parts and enclosures

Sep 24,2021

2,971 views

The Breadboarded Self Balancing Robot

A Self Balancing Robot made around a breadboard.

2971

1

0

10.00 (1)

Published: Sep 24,2021

Standard PCB

Purchase

Donation Received ($)

PCBWay Donate 10% cost To Author

*PCBWay community is a sharing platform. We are not responsible for any design issues and parameter issues (board thickness, surface finish, etc.) you choose.

Copy this HTML into your page to embed a link to order this shared project

Copy

Under the

Attribution-NonCommercial-ShareAlike (CC BY-NC-SA)

License.

- Comments(0)

- Likes(1)

Upload photo

You can only upload 5 files in total. Each file cannot exceed 2MB. Supports JPG, JPEG, GIF, PNG, BMP

0 / 10000

It looks like you have not written anything. Please add a comment and try again.

You can upload up to 5 images!

Image size should not exceed 2MB!

File format not supported!

View More

-

Engineer

Sep 30,2021

Engineer

Sep 30,2021

View More

VOTING

1 votes

- 1 USER VOTES

10.00

- YOUR VOTE 0.00 0.00

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

Design

1/4

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

Usability

2/4

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

Creativity

3/4

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

Content

4/4

-

10design

-

10usability

-

10creativity

-

10content

10.00

More by Aditya ATOM

More by Aditya ATOM

You may also like

-

-

mammoth-3D SLM Voron Toolhead – Manual Drill & Tap Edition

140 0 0 -

-

AEL-2011 Power Supply Module

653 0 2 -

AEL-2011 50W Power Amplifier

567 0 2 -

-

-

Custom Mechanical Keyboard

769 0 0 -

Tester for Touch Screen Digitizer without using microcontroller

395 2 2 -

Audio reactive glow LED wristband/bracelet with NFC / RFID-Tags

363 0 1 -

-