USB Fast charger interface for mobile applications

Fast Charger design for mobile phones with vendor specific USB enumeration

Have you ever plugged in your fast charging enabled Samsung mobile to a HTC charger and wondered why it doesn’t fast charge? or why your apple product does not charge as fast as you would like it to when you plug it into a non-stock charger? This blog describes the tale behind the fast charging compatibility of mobiles and how to design a universal fast charger circuit.

What has my charger got to do with fast charging?

A short answer would be “next to nothing”. Fast charging is facilitated by the charge controller IC that comes inside your mobile phone and provides the battery with certain charging patterns depending on the factors such as charge percentage, rate of battery drain, battery temperature, etc. The battery charger IC manages the current drawn from the charger and feeds it to the battery as per the implemented charging algorithm. in most algorithms, when battery level is less than 20%, a low current (around 800mA) is drawn from the charger and when the battery level is in 20%-80%, a high current is drawn (1.5-2.4A) to engage in fast charging.

Therefore, ideally, the only thing that the charger has got to do with fast charging is that it should be able to provide the required high current during the fast charging phase.for example, if your Samsung charger is rated at (say) 2A which means it is capable of giving out up to 2A but not necessarily mean that the phone will draw 2A current during its entire charging cycle from 0%-100%.

So why doesn’t my phone fast charge when I plug it into another charger of a different brand having the same current rating?

When a phone is plugged into a charger and if it were to draw the required current for charging, straight away and if the charger doesn’t have the capacity to deliver the required current, it will end up damaging the charger. For example, if you were to plug in a mobile requiring 1.5A charge current during its fast charging phase, to a charger rated at 1A, chances are you will end-up burning the charger. To avoid this from happening, smart phones communicate with the charger to know what the current delivering capability of the charger is. This communication scheme between the phone and the charger (called enumeration) is directed by the BC1.1 guidelines.(http://kinetis.pl/sites/default/files/BC1.2_FINAL.pdf)

However, in reality, mobile phone manufacturers have implemented their own enumeration protocols. Due to this, it can be observed that when a mobile phone is connected to the charger, not only it will check the current supplying capability of the charger but it will also check whether the charger is from the same brand as the phone. This may also be a measure taken by the mobile phone manufacturers to constrain the users from using other available chargers if the original charger is damaged or lost (I don’t know).

Anyway, how the mobile phone identifies the charger as a “compatible” one is interesting. All the manufacturers use the D+ and D- lines of the usb charger cable to identify the charger type. The charger provides a predefined voltage combination to the USB datalines which is observed by the mobile phone to determine the compatibility

Manufacturers such as Sony, Huawei, and other Chinese brands comply with the B.C1.1 standard and they tend to identify the charger as fast charging compatible, if the data lines of the charging cable are shorted at the charger end.

Apple, depending on the mobile, tends to identify the lightening charge compatibility if the data lines D+, D- have either (+2.0V, +2.4V) or (+2.0V, +2.7V) or (+2.7V, +2.7V). However based on my observations, (2.7V, 2.7V) combination on datalines is identified as lightening charge compatible by all the apple products I’ve tested, including i-pad.

In Samsung chargers, have either (1.2V, 1.2V) or (+1.2V, 2.0V) combinations on the datalines to signal the mobile phone about fast charging compatibility.

These various combinations makes it an absolute nightmare to design a universal fast charger which can cater fast charging to all the mobile phone brands. Following are two methods I have tried and tested, one not so layman and one layman approach, to design a universal fast charger.

The “not so layman” approach.

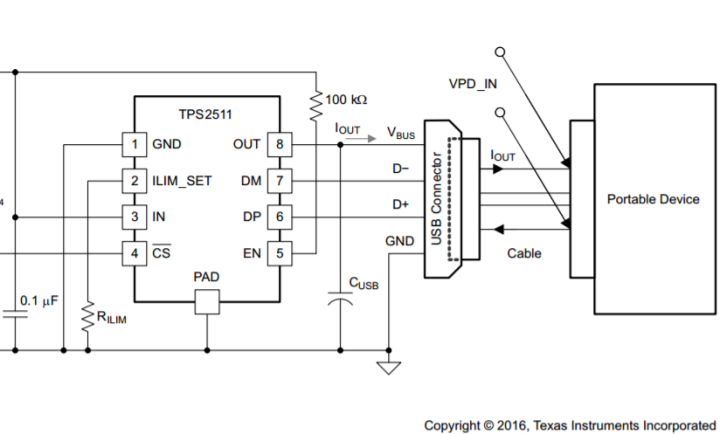

In this approach, I tried out the TPS2511 (http://www.ti.com/lit/ds/symlink/tps2511.pdf) USB enumerator IC from Texas Instruments. This IC follows a handshaking enumeration procedure with the mobile device connected which then automatically detects the required USB data line voltages to enable the fast charging functionality of the connected mobile phone. It also has a current limiting pin which can be set using a resistor and is capable of allowing a current of up to 2.3A. This current limiting function shuts down the circuit output when the current has exceeded the limit set by the R(ILim) resistor. The IC comes in a handy SMD package where the complete circuit can be implemented in a 5cm x 2.5cm PCB.

(Please ignore the three USB ports since only one of them will be used at any given time.)

High quality PCBs were manufactured through www.pcbway.com which gives amazing deals on dual layer pcb prototyping.

Using the above implementation, it was managed to verify the fast charging functionality with Samsung, Huawei, Apple and Sony mobile phones along with few other Chinese mobiles. (only galaxy note 5 didn’t fast charge as per current observations. It was not slow charging as when it is connected to a computer but indicated as connected to an AC adapter without fast charge)

The “Layman” approach.

If you can’t be bothered about getting the TPS2511 circuitry made, there’s an easy way around. I cannot guarantee this will work in all the cases but it seems to work with almost all the test cases I considered. The BC1.1 requires the USB data lines to be shorted for the device to know that it can draw up to 1.5A current. it doesn’t specify a voltage for the data lines as such but merely checks whether they are short circuited or not. Th apple enumeration protocol that works with all the apple devices requires 2.7V on both data lines.

If you were to short circuit the data-lines and keep the short circuited data lines at a potential of 2.7V, it seems to be recognized by both apple and BC1.1 compliant devices as fast charging compatible charger port, in their own way. And the cherry on the cake is that it will be recognized by some of the Samsung devices as well, as a fast charging compatible charger port. You can use a resistor divider and easily provide approximately 2.7V on both data-lines. However I must mention that I didn’t check this layman approach extensively but it seems to work with most of the devices so I can’t re-assure you it will work for certain.

USB Fast charger interface for mobile applications

*PCBWay community is a sharing platform. We are not responsible for any design issues and parameter issues (board thickness, surface finish, etc.) you choose.

- Comments(1)

- Likes(6)

-

Engineer

Sep 08,2022

Engineer

Sep 08,2022

-

James Hauser

Oct 31,2019

James Hauser

Oct 31,2019

-

Guillermo Gonzalez

Sep 28,2019

Guillermo Gonzalez

Sep 28,2019

-

Robert Scott

Aug 17,2017

Robert Scott

Aug 17,2017

-

tkshamshee

Aug 16,2017

tkshamshee

Aug 16,2017

-

Engineer

Aug 03,2017

Engineer

Aug 03,2017

- 2 USER VOTES

- YOUR VOTE 0.00 0.00

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

10design

-

10usability

-

10creativity

-

10content

-

10design

-

10usability

-

10creativity

-

10content

More by Akila Kasunjith Hettiarachchi

More by Akila Kasunjith Hettiarachchi

-

-

AEL-2011 Power Supply Module

515 0 2 -

AEL-2011 50W Power Amplifier

474 0 2 -

-

-

Custom Mechanical Keyboard

691 0 0 -

Tester for Touch Screen Digitizer without using microcontroller

322 2 2 -

Audio reactive glow LED wristband/bracelet with NFC / RFID-Tags

306 0 1 -

-

-

Top Solder Mask

Top Solder Mask

Top Paste Mask

Top Paste Mask

Top Overlay

Top Overlay

Top Copper Layer

Top Copper Layer

Pad Master Top

Pad Master Top

Pad Master Bottom

Pad Master Bottom

Mechanical Layer 15

Mechanical Layer 15

Mechanical Layer 13

Mechanical Layer 13

Mechanical Layer 1

Mechanical Layer 1

Drill Guide

Drill Guide

Drill Drawing

Drill Drawing

Bottom Solder Mask

Bottom Solder Mask

Bottom Copper Layer

Bottom Copper Layer

Bottom

Bottom

Top

Top