|

|

Arduino Nanıo |

x 1 | |

|

|

1N4148WTDIODES

|

x 4 | |

|

|

BUTTON1null

|

x 4 | |

|

|

1N5408 |

x 1 | |

|

3306F-1-104Bourns Inc.

|

x 1 | |

|

SFMC-107-01-S-DSAMTEC INC.

|

x 1 |

|

Arduino nanoArduino

|

|

|

arduino IDEArduino

|

Build a MIND-BLOWING Mini Oscilloscope at Home with EST Projects

Build a MIND-BLOWING Mini Oscilloscope at Home with EST Projects

Ever wondered how you can measure and visualize electronic signals right at your desk? With this DIY Mini Oscilloscope project, you can! In this guide, we will walk through building a simple yet powerful oscilloscope using affordable and easy-to-find components. This is the perfect project for electronics enthusiasts looking to take their DIY skills to the next level.

Let’s break down how you can make this MIND-BLOWING mini oscilloscope using an Arduino Nano, LM2596 for the power supply, buttons for user control, a custom PCB, and more!

Materials Required

Here’s what you’ll need for this project:

Arduino Nano: The main controller for signal processing.

LM2596-05 Buck Converter: For the power supply (to step down voltage).

0.96" OLED Display: To visualize the signals.

4 Push Buttons:

Button 1: Menu Select

Button 2: UP

Button 3: DOWN

Button 4: HOLD

Resistors:

390KΩ

100KΩ

104 Variable Resistor: To control input signals.

1n4148 or 1n4007 Diodes: For pull-up mode.

Power Socket

AC 2 Pin Terminal Block

PCB: Custom-designed PCB from PCBway.

Wires, Breadboard, Soldering tools (for assembly).

Circuit Design and Button Configuration

For this project, we will be using four buttons that act as the control interface for the oscilloscope:

Menu Select – Button to toggle between different functions.

Up – Increases values or moves up in the menu.

Down – Decreases values or moves down in the menu.

Hold – Freezes the current waveform on the display.

Button Pin Configuration

Each button will be connected to specific pins on the Arduino Nano and configured as INPUT_PULLUP to ensure reliable operation.

We’ll be using 4 buttons for control:

Button 1 (Menu Select): Wired to pin 8.

Button 2 (UP): Wired to pin 9.

Button 3 (DOWN): Wired to pin 10.

Button 4 (HOLD): Wired to pin 11.

Each button will use the INPUT_PULLUP mode in Arduino to ensure stable signal readings. Here’s how you’ll set them up in the code:

-----------------------------------------------------------------------------------------

pinMode(2, INPUT_PULLUP); // Button pressed interrupt (int.0 IRQ)

pinMode(8, INPUT_PULLUP); // Select button

pinMode(9, INPUT_PULLUP); // Up button

pinMode(10, INPUT_PULLUP); // Down button

pinMode(11, INPUT_PULLUP); // Hold button

pinMode(12, INPUT); // 1/10 attenuator (Off=High-Z, Enable=Output Low)

pinMode(13, OUTPUT); // LED for status indication

--------------------------------------------------------------------------------------------

By using INPUT_PULLUP, the buttons are kept in a high state when not pressed, reducing the chance of false triggering due to noise. When a button is pressed, the state changes to LOW, triggering the appropriate function in the code.

Signal Attenuation and Input Control

To allow the oscilloscope to handle different signal ranges, we’ll implement a 1/10 attenuator using pin 12. This will allow us to switch between high-impedance (Off) and low-impedance (Enable) states, enabling better signal control.

--------------------------------------------------------------------------------------------

pinMode(12, INPUT); // 1/10 attenuator (Off=High-Z, Enable=Output Low)

--------------------------------------------------------------------------------------------

Display Setup with OLED

Using a 0.96" OLED display is perfect for visualizing the signal data. You can use the Adafruit SSD1306 library to interface the OLED with the Arduino Nano.

Install the library and initialize the display in the code:

--------------------------------------------------------------------------------------------

#include <Adafruit_GFX.h>

#include <Adafruit_SSD1306.h>

#define SCREEN_WIDTH 128

#define SCREEN_HEIGHT 64

Adafruit_SSD1306 display(SCREEN_WIDTH, SCREEN_HEIGHT, &Wire, -1);

void setup() {

if(!display.begin(SSD1306_SWITCHCAPVCC, 0x3C)) {

Serial.println(F("SSD1306 allocation failed"));

for(;;);

}

display.clearDisplay();

display.display();

}

--------------------------------------------------------------------------------------------

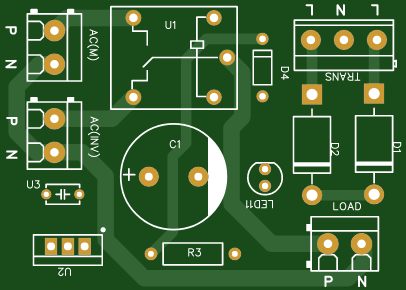

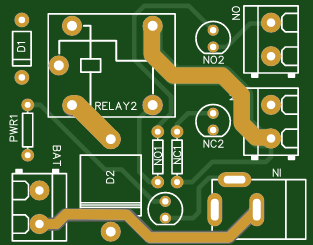

PCB Assembly

Design the PCB to make the connections tidy and compact. You can order a custom PCB from PCBway. It will include the necessary connections for the Arduino Nano, resistors, buttons, and power supply.

Once the PCB arrives, the components will be soldered as per the design.

Video Reference

#include <Wire.h>

#include <Adafruit_GFX.h>

//#include <Adafruit_SSD1306.h>

#include <Adafruit_SH1106.h> // https://github.com/wonho-maker/Adafruit_SH1106

#include <EEPROM.h>

#define SCREEN_WIDTH 128 // OLED display width

#define SCREEN_HEIGHT 64 // OLED display height

#define REC_LENG 200 // size of wave data buffer

#define MIN_TRIG_SWING 5 // minimum trigger swing.(Display "Unsync" if swing smaller than this value

// Declaration for an SSD1306 display connected to I2C (SDA, SCL pins)

#define OLED_RESET -1 // Reset pin # (or -1 if sharing Arduino reset pin)

//Adafruit_SSD1306 oled(SCREEN_WIDTH, SCREEN_HEIGHT, &Wire, OLED_RESET); // device name is oled

Adafruit_SH1106 oled(OLED_RESET); // use this when SH1106

// Range name table (those are stored in flash memory)

const char vRangeName[10][5] PROGMEM = {"A50V", "A 5V", " 50V", " 20V", " 10V", " 5V", " 2V", " 1V", "0.5V", "0.2V"}; // Vertical display character (number of characters including \ 0 is required)

const char * const vstring_table[] PROGMEM = {vRangeName[0], vRangeName[1], vRangeName[2], vRangeName[3], vRangeName[4], vRangeName[5], vRangeName[6], vRangeName[7], vRangeName[8], vRangeName[9]};

const char hRangeName[10][6] PROGMEM = {"200ms", "100ms", " 50ms", " 20ms", " 10ms", " 5ms", " 2ms", " 1ms", "500us", "200us"}; // Hrizontal display characters

const char * const hstring_table[] PROGMEM = {hRangeName[0], hRangeName[1], hRangeName[2], hRangeName[3], hRangeName[4], hRangeName[5], hRangeName[6], hRangeName[7], hRangeName[8], hRangeName[9]};

const PROGMEM float hRangeValue[] = { 0.2, 0.1, 0.05, 0.02, 0.01, 0.005, 0.002, 0.001, 0.5e-3, 0.2e-3}; // horizontal range value in second. ( = 25pix on screen)

int waveBuff[REC_LENG]; // wave form buffer (RAM remaining capacity is barely)

char chrBuff[8]; // display string buffer

char hScale[] = "xxxAs"; // horizontal scale character

char vScale[] = "xxxx"; // vartical scale

float lsb5V = 0.00566826; // sensivity coefficient of 5V range. std=0.00563965 1.1*630/(1024*120)

float lsb50V = 0.05243212; // sensivity coefficient of 50V range. std=0.0512898 1.1*520.91/(1024*10.91)

volatile int vRange; // V-range number 0:A50V, 1:A 5V, 2:50V, 3:20V, 4:10V, 5:5V, 6:2V, 7:1V, 8:0.5V, 9:0.2V

volatile int hRange; // H-range nubmer 0:200ms, 1:100ms, 2:50ms, 3:20ms, 4:10ms, 5:5ms, 6;2ms, 7:1ms, 8:500us, 9;200us

volatile int trigD; // trigger slope flag, 0:positive 1:negative

volatile int scopeP; // operation scope position number. 0:Veratical, 1:Hrizontal, 2:Trigger slope

volatile boolean hold = false; // hold flag

volatile boolean switchPushed = false; // flag of switch pusshed !

volatile int saveTimer; // remaining time for saving EEPROM

int timeExec; // approx. execution time of current range setting (ms)

int dataMin; // buffer minimum value (smallest=0)

int dataMax; // maximum value (largest=1023)

int dataAve; // 10 x average value (use 10x value to keep accuracy. so, max=10230)

int rangeMax; // buffer value to graph full swing

int rangeMin; // buffer value of graph botto

int rangeMaxDisp; // display value of max. (100x value)

int rangeMinDisp; // display value if min.

int trigP; // trigger position pointer on data buffer

boolean trigSync; // flag of trigger detected

int att10x; // 10x attenetor ON (effective when 1)

float waveFreq; // frequency (Hz)

float waveDuty; // duty ratio (%)

void setup() {

pinMode(2, INPUT_PULLUP); // button pussed interrupt (int.0 IRQ)

pinMode(8, INPUT_PULLUP); // Select button

pinMode(9, INPUT_PULLUP); // Up

pinMode(10, INPUT_PULLUP); // Down

pinMode(11, INPUT_PULLUP); // Hold

pinMode(12, INPUT); // 1/10 attenuator(Off=High-Z, Enable=Output Low)

pinMode(13, OUTPUT); // LED

// oled.begin(SSD1306_SWITCHCAPVCC, 0x3C) { // select 3C or 3D (set your OLED I2C address)

oled.begin(SH1106_SWITCHCAPVCC, 0x3C); // use this when SH1106

auxFunctions(); // Voltage measure (never return)

loadEEPROM(); // read last settings from EEPROM

analogReference(INTERNAL); // ADC full scale = 1.1V

attachInterrupt(0, pin2IRQ, FALLING); // activate IRQ at falling edge mode

startScreen(); // display start message

}

void loop() {

setConditions(); // set measurment conditions

digitalWrite(13, HIGH); // flash LED

readWave(); // read wave form and store into buffer memory

digitalWrite(13, LOW); // stop LED

setConditions(); // set measurment conditions again (reflect change during measure)

dataAnalize(); // analize data

writeCommonImage(); // write fixed screen image (2.6ms)

plotData(); // plot waveform (10-18ms)

dispInf(); // display information (6.5-8.5ms)

oled.display(); // send screen buffer to OLED (37ms)

saveEEPROM(); // save settings to EEPROM if necessary

while (hold == true) { // wait if Hold flag ON

dispHold();

delay(10);

} // loop cycle speed = 60-470ms (buffer size = 200)

}

void setConditions() { // measuring condition setting

// get range name from PROGMEM

strcpy_P(hScale, (char*)pgm_read_word(&(hstring_table[hRange]))); // H range name

strcpy_P(vScale, (char*)pgm_read_word(&(vstring_table[vRange]))); // V range name

switch (vRange) { // setting of Vrange

case 0: { // Auto50V range

att10x = 1; // use input attenuator

break;

}

case 1: { // Auto 5V range

att10x = 0; // no attenuator

break;

}

case 2: { // 50V range

rangeMax = 50 / lsb50V; // set full scale pixcel count number

rangeMaxDisp = 5000; // vartical scale (set100x value)

rangeMin = 0;

rangeMinDisp = 0;

att10x = 1; // use input attenuator

break;

}

case 3: { // 20V range

rangeMax = 20 / lsb50V; // set full scale pixcel count number

rangeMaxDisp = 2000;

rangeMin = 0;

rangeMinDisp = 0;

att10x = 1; // use input attenuator

break;

}

case 4: { // 10V range

rangeMax = 10 / lsb50V; // set full scale pixcel count number

rangeMaxDisp = 1000;

rangeMin = 0;

rangeMinDisp = 0;

att10x = 1; // use input attenuator

break;

}

case 5: { // 5V range

rangeMax = 5 / lsb5V; // set full scale pixcel count number

rangeMaxDisp = 500;

rangeMin = 0;

rangeMinDisp = 0;

att10x = 0; // no input attenuator

break;

}

case 6: { // 2V range

rangeMax = 2 / lsb5V; // set full scale pixcel count number

rangeMaxDisp = 200;

rangeMin = 0;

rangeMinDisp = 0;

att10x = 0; // no input attenuator

break;

}

case 7: { // 1V range

rangeMax = 1 / lsb5V; // set full scale pixcel count number

rangeMaxDisp = 100;

rangeMin = 0;

rangeMinDisp = 0;

att10x = 0; // no input attenuator

break;

}

case 8: { // 0.5V range

rangeMax = 0.5 / lsb5V; // set full scale pixcel count number

rangeMaxDisp = 50;

rangeMin = 0;

rangeMinDisp = 0;

att10x = 0; // no input attenuator

break;

}

case 9: { // 0.5V range

rangeMax = 0.2 / lsb5V; // set full scale pixcel count number

rangeMaxDisp = 20;

rangeMin = 0;

rangeMinDisp = 0;

att10x = 0; // no input attenuator

break;

}

}

}

void writeCommonImage() { // Common screen image drawing

oled.clearDisplay(); // erase all(0.4ms)

oled.setTextColor(WHITE); // write in white character

oled.setCursor(85, 0); // Start at top-left corner

oled.println(F("av v")); // 1-st line fixed characters

oled.drawFastVLine(26, 9, 55, WHITE); // left vartical line

oled.drawFastVLine(127, 9, 3, WHITE); // right vrtical line up

oled.drawFastVLine(127, 61, 3, WHITE); // right vrtical line bottom

oled.drawFastHLine(24, 9, 7, WHITE); // Max value auxiliary mark

oled.drawFastHLine(24, 36, 2, WHITE);

oled.drawFastHLine(24, 63, 7, WHITE);

oled.drawFastHLine(51, 9, 3, WHITE); // Max value auxiliary mark

oled.drawFastHLine(51, 63, 3, WHITE);

oled.drawFastHLine(76, 9, 3, WHITE); // Max value auxiliary mark

oled.drawFastHLine(76, 63, 3, WHITE);

oled.drawFastHLine(101, 9, 3, WHITE); // Max value auxiliary mark

oled.drawFastHLine(101, 63, 3, WHITE);

oled.drawFastHLine(123, 9, 5, WHITE); // right side Max value auxiliary mark

oled.drawFastHLine(123, 63, 5, WHITE);

for (int x = 26; x <= 128; x += 5) {

oled.drawFastHLine(x, 36, 2, WHITE); // Draw the center line (horizontal line) with a dotted line

}

for (int x = (127 - 25); x > 30; x -= 25) {

for (int y = 10; y < 63; y += 5) {

oled.drawFastVLine(x, y, 2, WHITE); // Draw 3 vertical lines with dotted lines

}

}

}

void readWave() { // Record waveform to memory array

if (att10x == 1) { // if 1/10 attenuator required

pinMode(12, OUTPUT); // assign attenuator controle pin to OUTPUT,

digitalWrite(12, LOW); // and output LOW (output 0V)

} else { // if not required

pinMode(12, INPUT); // assign the pin input (Hi-z)

}

switchPushed = false; // Clear switch operation flag

switch (hRange) { // set recording conditions in accordance with the range number

case 0: { // 200ms range

timeExec = 1600 + 60; // Approximate execution time(ms) Used for countdown until saving to EEPROM

ADCSRA = ADCSRA & 0xf8; // clear bottom 3bit

ADCSRA = ADCSRA | 0x07; // dividing ratio = 128 (default of Arduino)

for (int i = 0; i < REC_LENG; i++) { // up to rec buffer size

waveBuff[i] = analogRead(0); // read and save approx 112us

delayMicroseconds(7888); // timing adjustment

if (switchPushed == true) { // if any switch touched

switchPushed = false;

break; // abandon record(this improve response)

}

}

break;

}

case 1: { // 100ms range

timeExec = 800 + 60; // Approximate execution time(ms) Used for countdown until saving to EEPROM

ADCSRA = ADCSRA & 0xf8; // clear bottom 3bit

ADCSRA = ADCSRA | 0x07; // dividing ratio = 128 (default of Arduino)

for (int i = 0; i < REC_LENG; i++) { // up to rec buffer size

waveBuff[i] = analogRead(0); // read and save approx 112us

// delayMicroseconds(3888); // timing adjustmet

delayMicroseconds(3860); // timing adjustmet tuned

if (switchPushed == true) { // if any switch touched

switchPushed = false;

break; // abandon record(this improve response)

}

}

break;

}

case 2: { // 50ms range

timeExec = 400 + 60; // Approximate execution time(ms)

ADCSRA = ADCSRA & 0xf8; // clear bottom 3bit

ADCSRA = ADCSRA | 0x07; // dividing ratio = 128 (default of Arduino)

for (int i = 0; i < REC_LENG; i++) { // up to rec buffer size

waveBuff[i] = analogRead(0); // read and save approx 112us

// delayMicroseconds(1888); // timing adjustmet

delayMicroseconds(1880); // timing adjustmet tuned

if (switchPushed == true) { // if any switch touched

break; // abandon record(this improve response)

}

}

break;

}

case 3: { // 20ms range

timeExec = 160 + 60; // Approximate execution time(ms)

ADCSRA = ADCSRA & 0xf8; // clear bottom 3bit

ADCSRA = ADCSRA | 0x07; // dividing ratio = 128 (default of Arduino)

for (int i = 0; i < REC_LENG; i++) { // up to rec buffer size

waveBuff[i] = analogRead(0); // read and save approx 112us

// delayMicroseconds(688); // timing adjustmet

delayMicroseconds(686); // timing adjustmet tuned

if (switchPushed == true) { // if any switch touched

break; // abandon record(this improve response)

}

}

break;

}

case 4: { // 10ms range

timeExec = 80 + 60; // Approximate execution time(ms)

ADCSRA = ADCSRA & 0xf8; // clear bottom 3bit

ADCSRA = ADCSRA | 0x07; // dividing ratio = 128 (default of Arduino)

for (int i = 0; i < REC_LENG; i++) { // up to rec buffer size

waveBuff[i] = analogRead(0); // read and save approx 112us

// delayMicroseconds(288); // timing adjustmet

delayMicroseconds(287); // timing adjustmet tuned

if (switchPushed == true) { // if any switch touched

break; // abandon record(this improve response)

}

}

break;

}

case 5: { // 5ms range

timeExec = 40 + 60; // Approximate execution time(ms)

ADCSRA = ADCSRA & 0xf8; // clear bottom 3bit

ADCSRA = ADCSRA | 0x07; // dividing ratio = 128 (default of Arduino)

for (int i = 0; i < REC_LENG; i++) { // up to rec buffer size

waveBuff[i] = analogRead(0); // read and save approx 112μs

// delayMicroseconds(88); // timing adjustmet

delayMicroseconds(87); // timing adjustmet tuned

if (switchPushed == true) { // if any switch touched

break; // abandon record(this improve response)

}

}

break;

}

case 6: { // 2ms range

timeExec = 16 + 60; // Approximate execution time(ms)

ADCSRA = ADCSRA & 0xf8; // clear bottom 3bit

ADCSRA = ADCSRA | 0x06; // dividing ratio = 64 (0x1=2, 0x2=4, 0x3=8, 0x4=16, 0x5=32, 0x6=64, 0x7=128)

for (int i = 0; i < REC_LENG; i++) { // up to rec buffer size

waveBuff[i] = analogRead(0); // read and save approx 56us

// delayMicroseconds(24); // timing adjustmet

delayMicroseconds(23); // timing adjustmet tuned

}

break;

}

case 7: { // 1ms range

timeExec = 8 + 60; // Approximate execution time(ms)

ADCSRA = ADCSRA & 0xf8; // clear bottom 3bit

ADCSRA = ADCSRA | 0x05; // dividing ratio = 16 (0x1=2, 0x2=4, 0x3=8, 0x4=16, 0x5=32, 0x6=64, 0x7=128)

for (int i = 0; i < REC_LENG; i++) { // up to rec buffer size

waveBuff[i] = analogRead(0); // read and save approx 28us

// delayMicroseconds(12); // timing adjustmet

delayMicroseconds(10); // timing adjustmet tuned

}

break;

}

case 8: { // 500us range

timeExec = 4 + 60; // Approximate execution time(ms)

ADCSRA = ADCSRA & 0xf8; // clear bottom 3bit

ADCSRA = ADCSRA | 0x04; // dividing ratio = 16(0x1=2, 0x2=4, 0x3=8, 0x4=16, 0x5=32, 0x6=64, 0x7=128)

for (int i = 0; i < REC_LENG; i++) { // up to rec buffer size

waveBuff[i] = analogRead(0); // read and save approx 16us

delayMicroseconds(4); // timing adjustmet

// time fine adjustment 0.0625 x 8 = 0.5us(nop=0.0625us @16MHz)

asm("nop"); asm("nop"); asm("nop"); asm("nop"); asm("nop"); asm("nop"); asm("nop"); asm("nop");

}

break;

}

case 9: { // 200us range

timeExec = 2 + 60; // Approximate execution time(ms)

ADCSRA = ADCSRA & 0xf8; // clear bottom 3bit

ADCSRA = ADCSRA | 0x02; // dividing ratio = 4(0x1=2, 0x2=4, 0x3=8, 0x4=16, 0x5=32, 0x6=64, 0x7=128)

for (int i = 0; i < REC_LENG; i++) { // up to rec buffer size

waveBuff[i] = analogRead(0); // read and save approx 6us

// time fine adjustment 0.0625 * 20 = 1.25us (nop=0.0625us @16MHz)

asm("nop"); asm("nop"); asm("nop"); asm("nop"); asm("nop"); asm("nop"); asm("nop"); asm("nop"); asm("nop"); asm("nop");

asm("nop"); asm("nop"); asm("nop"); asm("nop"); asm("nop"); asm("nop"); asm("nop"); asm("nop"); asm("nop"); asm("nop");

}

break;

}

}

}

void dataAnalize() { // get various information from wave form

int d;

long sum = 0;

// search max and min value

dataMin = 1023; // min value initialize to big number

dataMax = 0; // max value initialize to small number

for (int i = 0; i < REC_LENG; i++) { // serach max min value

d = waveBuff[i];

sum = sum + d;

if (d < dataMin) { // update min

dataMin = d;

}

if (d > dataMax) { // updata max

dataMax = d;

}

}

// calculate average

dataAve = (sum + 10) / 20; // Average value calculation (calculated by 10 times to improve accuracy)

// decide display's max min value

if (vRange <= 1) { // if Autorabge(Range number <=1)

rangeMin = dataMin - 20; // maintain bottom margin 20

rangeMin = (rangeMin / 10) * 10; // round 10

if (rangeMin < 0) {

rangeMin = 0; // no smaller than 0

}

rangeMax = dataMax + 20; // set display top at data max +20

rangeMax = ((rangeMax / 10) + 1) * 10; // round up 10

if (rangeMax > 1020) {

rangeMax = 1023; // if more than 1020, hold down at 1023

}

if (att10x == 1) { // if 10x attenuator used

rangeMaxDisp = 100 * (rangeMax * lsb50V); // display range is determined by the data.(the upper limit is up to the full scale of the ADC)

rangeMinDisp = 100 * (rangeMin * lsb50V); // lower depend on data, but zero or more

} else { // if no attenuator used

rangeMaxDisp = 100 * (rangeMax * lsb5V);

rangeMinDisp = 100 * (rangeMin * lsb5V);

}

} else { // if fix range

// Write necessary code here (none for now)

}

// Trigger position search

for (trigP = ((REC_LENG / 2) - 51); trigP < ((REC_LENG / 2) + 50); trigP++) { // Find the points that straddle the median at the center ± 50 of the data range

if (trigD == 0) { // if trigger direction is positive

if ((waveBuff[trigP - 1] < (dataMax + dataMin) / 2) && (waveBuff[trigP] >= (dataMax + dataMin) / 2)) {

break; // positive trigger position found !

}

} else { // trigger direction is negative

if ((waveBuff[trigP - 1] > (dataMax + dataMin) / 2) && (waveBuff[trigP] <= (dataMax + dataMin) / 2)) {

break;

} // negative trigger poshition found !

}

}

trigSync = true;

if (trigP >= ((REC_LENG / 2) + 50)) { // If the trigger is not found in range

trigP = (REC_LENG / 2); // Set it to the center for the time being

trigSync = false; // set Unsync display flag

}

if ((dataMax - dataMin) <= MIN_TRIG_SWING) { // amplitude of the waveform smaller than the specified value

trigSync = false; // set Unsync display flag

}

freqDuty();

}

void freqDuty() { // detect frequency and duty cycle value from waveform data

int swingCenter; // center of wave (half of p-p)

float p0 = 0; // 1-st posi edge

float p1 = 0; // total length of cycles

float p2 = 0; // total length of pulse high time

float pFine = 0; // fine position (0-1.0)

float lastPosiEdge; // last positive edge position

float pPeriod; // pulse period

float pWidth; // pulse width

int p1Count = 0; // wave cycle count

int p2Count = 0; // High time count

boolean a0Detected = false;

// boolean b0Detected = false;

boolean posiSerch = true; // true when serching posi edge

swingCenter = (3 * (dataMin + dataMax)) / 2; // calculate wave center value

for (int i = 1; i < REC_LENG - 2; i++) { // scan all over the buffer

if (posiSerch == true) { // posi slope (frequency serch)

if ((sum3(i) <= swingCenter) && (sum3(i + 1) > swingCenter)) { // if across the center when rising (+-3data used to eliminate noize)

pFine = (float)(swingCenter - sum3(i)) / ((swingCenter - sum3(i)) + (sum3(i + 1) - swingCenter) ); // fine cross point calc.

if (a0Detected == false) { // if 1-st cross

a0Detected = true; // set find flag

p0 = i + pFine; // save this position as startposition

} else {

p1 = i + pFine - p0; // record length (length of n*cycle time)

p1Count++;

}

lastPosiEdge = i + pFine; // record location for Pw calcration

posiSerch = false;

}

} else { // nega slope serch (duration serch)

if ((sum3(i) >= swingCenter) && (sum3(i + 1) < swingCenter)) { // if across the center when falling (+-3data used to eliminate noize)

pFine = (float)(sum3(i) - swingCenter) / ((sum3(i) - swingCenter) + (swingCenter - sum3(i + 1)) );

if (a0Detected == true) {

p2 = p2 + (i + pFine - lastPosiEdge); // calucurate pulse width and accumurate it

p2Count++;

}

posiSerch = true;

}

}

}

pPeriod = p1 / p1Count; // pulse period

pWidth = p2 / p2Count; // palse width

waveFreq = 1.0 / ((pgm_read_float(hRangeValue + hRange) * pPeriod) / 25.0); // frequency

waveDuty = 100.0 * pWidth / pPeriod; // duty ratio

}

int sum3(int k) { // Sum of before and after and own value

int m = waveBuff[k - 1] + waveBuff[k] + waveBuff[k + 1];

return m;

}

void startScreen() { // Staru up screen

oled.clearDisplay();

oled.setTextSize(1); // at double size character

oled.setTextColor(WHITE);

oled.setCursor(55, 0);

oled.println(F("Mini"));

oled.setCursor(30, 20);

oled.println(F("Oscilloscope"));

oled.setCursor(55, 42);

oled.println(F("v1.1"));

oled.display();

delay(1500);

oled.clearDisplay();

oled.setTextSize(1); // After this, standard font size

}

void dispHold() { // display "Hold"

oled.fillRect(42, 11, 24, 8, BLACK); // black paint 4 characters

oled.setCursor(42, 11);

oled.print(F("Hold")); // Hold

oled.display(); //

}

void dispInf() { // Display of various information

float voltage;

// display vertical sensitivity

oled.setCursor(2, 0); // around top left

oled.print(vScale); // vertical sensitivity value

if (scopeP == 0) { // if scoped

oled.drawFastHLine(0, 7, 27, WHITE); // display scoped mark at the bottom

oled.drawFastVLine(0, 5, 2, WHITE);

oled.drawFastVLine(26, 5, 2, WHITE);

}

// horizontal sweep speed

oled.setCursor(34, 0); //

oled.print(hScale); // display sweep speed (time/div)

if (scopeP == 1) { // if scoped

oled.drawFastHLine(32, 7, 33, WHITE); // display scoped mark at the bottom

oled.drawFastVLine(32, 5, 2, WHITE);

oled.drawFastVLine(64, 5, 2, WHITE);

}

// trigger polarity

oled.setCursor(75, 0); // at top center

if (trigD == 0) { // if positive

oled.print(char(0x18)); // up mark

} else {

oled.print(char(0x19)); // down mark ↓

}

if (scopeP == 2) { // if scoped

oled.drawFastHLine(71, 7, 13, WHITE); // display scoped mark at the bottom

oled.drawFastVLine(71, 5, 2, WHITE);

oled.drawFastVLine(83, 5, 2, WHITE);

}

// average voltage

if (att10x == 1) { // if 10x attenuator is used

voltage = dataAve * lsb50V / 10.0; // 50V range value

} else { // no!

voltage = dataAve * lsb5V / 10.0; // 5V range value

}

if (voltage < 10.0) { // if less than 10V

dtostrf(voltage, 4, 2, chrBuff); // format x.xx

} else { // no!

dtostrf(voltage, 4, 1, chrBuff); // format xx.x

}

oled.setCursor(98, 0); // around the top right

oled.print(chrBuff); // display average voltage圧の平均値を表示

// oled.print(saveTimer); // use here for debugging

// vartical scale lines

voltage = rangeMaxDisp / 100.0; // convart Max voltage

if (vRange == 1 || vRange > 4) { // if range below 5V or Auto 5V

dtostrf(voltage, 4, 2, chrBuff); // format *.**

} else { // no!

dtostrf(voltage, 4, 1, chrBuff); // format **.*

}

oled.setCursor(0, 9);

oled.print(chrBuff); // display Max value

voltage = (rangeMaxDisp + rangeMinDisp) / 200.0; // center value calculation

if (vRange == 1 || vRange > 4) { // if range below 5V or Auto 5V

dtostrf(voltage, 4, 2, chrBuff); // format *.**

} else { // no!

dtostrf(voltage, 4, 1, chrBuff); // format **.*

}

oled.setCursor(0, 33);

oled.print(chrBuff); // display the value

voltage = rangeMinDisp / 100.0; // convart Min vpltage

if (vRange == 1 || vRange > 4) { // if range below 5V or Auto 5V

dtostrf(voltage, 4, 2, chrBuff); // format *.**

} else { // no!

dtostrf(voltage, 4, 1, chrBuff); // format **.*

}

oled.setCursor(0, 57);

oled.print(chrBuff); // display the value

// display frequency, duty % or trigger missed

if (trigSync == false) { // If trigger point can't found

oled.fillRect(92, 14, 24, 8, BLACK); // black paint 4 character

oled.setCursor(92, 14); //

oled.print(F("unSync")); // dosplay Unsync

} else {

oled.fillRect(90, 12, 25, 9, BLACK); // erase Freq area

oled.setCursor(91, 13); // set display locatio

if (waveFreq < 100.0) { // if less than 100Hz

oled.print(waveFreq, 1); // display 99.9Hz

oled.print(F("Hz"));

} else if (waveFreq < 1000.0) { // if less than 1000Hz

oled.print(waveFreq, 0); // display 999Hz

oled.print(F("Hz"));

} else if (waveFreq < 10000.0) { // if less than 10kHz

oled.print((waveFreq / 1000.0), 2); // display 9.99kH

oled.print(F("kH"));

} else { // if more

oled.print((waveFreq / 1000.0), 1); // display 99.9kH

oled.print(F("kH"));

}

oled.fillRect(96, 21, 25, 10, BLACK); // erase Freq area (as small as possible)

oled.setCursor(97, 23); // set location

oled.print(waveDuty, 1); // display duty (High level ratio) in %

oled.print(F("%"));

}

}

void plotData() { // plot wave form on OLED

long y1, y2;

for (int x = 0; x <= 98; x++) {

y1 = map(waveBuff[x + trigP - 50], rangeMin, rangeMax, 63, 9); // convert to plot address

y1 = constrain(y1, 9, 63); // Crush(Saturate) the protruding part

y2 = map(waveBuff[x + trigP - 49], rangeMin, rangeMax, 63, 9); // to address calucurate

y2 = constrain(y2, 9, 63); //

oled.drawLine(x + 27, y1, x + 28, y2, WHITE); // connect between point

}

}

void saveEEPROM() { // Save the setting value in EEPROM after waiting a while after the button operation.

if (saveTimer > 0) { // If the timer value is positive,

saveTimer = saveTimer - timeExec; // Timer subtraction

if (saveTimer < 0) { // if time up

EEPROM.write(0, vRange); // save current status to EEPROM

EEPROM.write(1, hRange);

EEPROM.write(2, trigD);

EEPROM.write(3, scopeP);

}

}

}

void loadEEPROM() { // Read setting values from EEPROM (abnormal values will be corrected to default)

int x;

x = EEPROM.read(0); // vRange

if ((x < 0) || (9 < x)) { // if out side 0-9

x = 3; // default value

}

vRange = x;

x = EEPROM.read(1); // hRange

if ((x < 0) || (9 < x)) { // if out of 0-9

x = 3; // default value

}

hRange = x;

x = EEPROM.read(2); // trigD

if ((x < 0) || (1 < x)) { // if out of 0-1

x = 1; // default value

}

trigD = x;

x = EEPROM.read(3); // scopeP

if ((x < 0) || (2 < x)) { // if out of 0-2

x = 1; // default value

}

scopeP = x;

}

void auxFunctions() { // voltage meter function

float voltage;

long x;

if (digitalRead(8) == LOW) { // if SELECT button pushed, measure battery voltage

analogReference(DEFAULT); // ADC full scale set to Vcc

while (1) { // do forever

x = 0;

for (int i = 0; i < 100; i++) { // 100 times

x = x + analogRead(1); // read A1 pin voltage and accumulate

}

voltage = (x / 100.0) * 5.0 / 1023.0; // convert voltage value

oled.clearDisplay(); // all erase screen(0.4ms)

oled.setTextColor(WHITE); // write in white character

oled.setCursor(20, 16); //

oled.setTextSize(1); // standerd size character

oled.println(F("Battery voltage"));

oled.setCursor(35, 30); //

oled.setTextSize(2); // double size character

dtostrf(voltage, 4, 2, chrBuff); // display batterry voltage x.xxV

oled.print(chrBuff);

oled.println(F("V"));

oled.display();

delay(150);

}

}

if (digitalRead(9) == LOW) { // if UP button pushed, 5V range

analogReference(INTERNAL);

pinMode(12, INPUT); // Set the attenuator control pin to Hi-z (use as input)

while (1) { // do forever,

digitalWrite(13, HIGH); // flash LED

voltage = analogRead(0) * lsb5V; // measure voltage

oled.clearDisplay(); // erase screen (0.4ms)

oled.setTextColor(WHITE); // write in white character

oled.setCursor(26, 16); //

oled.setTextSize(1); // by standerd size character

oled.println(F("DVM 5V Range"));

oled.setCursor(35, 30); //

oled.setTextSize(2); // double size character

dtostrf(voltage, 4, 2, chrBuff); // display batterry voltage x.xxV

oled.print(chrBuff);

oled.println(F("V"));

oled.display();

digitalWrite(13, LOW); // stop LED flash

delay(150);

}

}

if (digitalRead(10) == LOW) { // if DOWN botton pushed, 50V range

analogReference(INTERNAL);

pinMode(12, OUTPUT); // Set the attenuator control pin to OUTPUT

digitalWrite(12, LOW); // output LOW

while (1) { // do forever

digitalWrite(13, HIGH); // flush LED

voltage = analogRead(0) * lsb50V; // measure voltage

oled.clearDisplay(); // erase screen (0.4ms)

oled.setTextColor(WHITE); // write in white character

oled.setCursor(26, 16); //

oled.setTextSize(1); // by standerd size character

oled.println(F("DVM 50V Range"));

oled.setCursor(35, 30); //

oled.setTextSize(2); // double size character

dtostrf(voltage, 4, 1, chrBuff); // display batterry voltage xx.xV

oled.print(chrBuff);

oled.println(F("V"));

oled.display();

digitalWrite(13, LOW); // stop LED flash

delay(150);

}

}

}

void uuPinOutputLow(unsigned int d, unsigned int a) { // 指定ピンを出力、LOWに設定

// PORTx =0, DDRx=1

unsigned int x;

x = d & 0x00FF; PORTD &= ~x; DDRD |= x;

x = d >> 8; PORTB &= ~x; DDRB |= x;

x = a & 0x003F; PORTC &= ~x; DDRC |= x;

}

void pin2IRQ() { // Pin2(int.0) interrupr handler

// Pin8,9,10,11 buttons are bundled with diodes and connected to Pin2.

// So, if any button is pressed, this routine will start.

int x; // Port information holding variable

x = PINB; // read port B status

if ( (x & 0x07) != 0x07) { // if bottom 3bit is not all Hi(any wer pressed)

saveTimer = 5000; // set EEPROM save timer to 5 secnd

switchPushed = true; // switch pushed falag ON

}

if ((x & 0x01) == 0) { // if select button(Pin8) pushed,

scopeP++; // forward scope position

if (scopeP > 2) { // if upper limit

scopeP = 0; // move to start position

}

}

if ((x & 0x02) == 0) { // if UP button(Pin9) pusshed, and

if (scopeP == 0) { // scoped vertical range

vRange++; // V-range up !

if (vRange > 9) { // if upper limit

vRange = 9; // stay as is

}

}

if (scopeP == 1) { // if scoped hrizontal range

hRange++; // H-range up !

if (hRange > 9) { // if upper limit

hRange = 9; // stay as is

}

}

if (scopeP == 2) { // if scoped trigger porality

trigD = 0; // set trigger porality to +

}

}

if ((x & 0x04) == 0) { // if DOWN button(Pin10) pusshed, and

if (scopeP == 0) { // scoped vertical range

vRange--; // V-range DOWN

if (vRange < 0) { // if bottom

vRange = 0; // stay as is

}

}

if (scopeP == 1) { // if scoped hrizontal range

hRange--; // H-range DOWN

if (hRange < 0) { // if bottom

hRange = 0; // satay as is

}

}

if (scopeP == 2) { // if scoped trigger porality

trigD = 1; // set trigger porality to -

}

}

if ((x & 0x08) == 0) { // if HOLD button(pin11) pushed

hold = ! hold; // revers the flag

}

}

Build a MIND-BLOWING Mini Oscilloscope at Home with EST Projects

*PCBWay community is a sharing platform. We are not responsible for any design issues and parameter issues (board thickness, surface finish, etc.) you choose.

- Comments(2)

- Likes(8)

-

Engineer

Sep 10,2025

Engineer

Sep 10,2025

-

Engineer

Aug 01,2025

Engineer

Aug 01,2025

-

Sergio Oliveira

May 29,2025

Sergio Oliveira

May 29,2025

-

HGTorin

Mar 23,2025

HGTorin

Mar 23,2025

-

Anthony Pedotto

Feb 22,2025

Anthony Pedotto

Feb 22,2025

-

Engineer

Oct 30,2024

Engineer

Oct 30,2024

-

Engineer

Oct 23,2024

Engineer

Oct 23,2024

-

Uber Blake

Oct 20,2024

Uber Blake

Oct 20,2024

- 0 USER VOTES

- YOUR VOTE 0.00 0.00

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

More by Estiak Khan

More by Estiak Khan

-

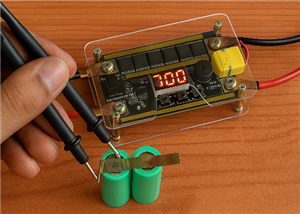

⚡ How to Make a DIY Spot Welding Machine at Home for 18650 Batteries | Full Circuit & Working

If you’re working on battery pack projects using 18650 lithium-ion cells, then you know how importan...

⚡ How to Make a DIY Spot Welding Machine at Home for 18650 Batteries | Full Circuit & Working

If you’re working on battery pack projects using 18650 lithium-ion cells, then you know how importan...

-

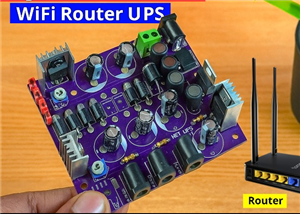

🔋 How to Make a Simple DIY Wi-Fi Router UPS at Home | Step-by-Step Guide with Circuit & PCB

Do you lose internet connection every time the power goes out?If yes, then this simple DIY Wi-Fi Rou...

🔋 How to Make a Simple DIY Wi-Fi Router UPS at Home | Step-by-Step Guide with Circuit & PCB

Do you lose internet connection every time the power goes out?If yes, then this simple DIY Wi-Fi Rou...

-

Automatic AC Changeover for Inverter

Automatic AC Changeover for Inverter – DIY Circuit GuideAre you tired of manually switching between ...

Automatic AC Changeover for Inverter

Automatic AC Changeover for Inverter – DIY Circuit GuideAre you tired of manually switching between ...

-

How to Make a 12V AC/DC Fan Controller Module

If you're looking for an efficient way to control a 12V fan using either AC or DC input, this DIY pr...

How to Make a 12V AC/DC Fan Controller Module

If you're looking for an efficient way to control a 12V fan using either AC or DC input, this DIY pr...

-

Autocut DC Mini IPS for DC 12V Load

Autocut DC Mini IPS for DC 12V LoadIf you are looking for a reliable Autocut DC Mini IPS for DC 12V ...

Autocut DC Mini IPS for DC 12V Load

Autocut DC Mini IPS for DC 12V LoadIf you are looking for a reliable Autocut DC Mini IPS for DC 12V ...

-

Build a 12V Battery Autocut System with LCD Display

Are you looking for an efficient and affordable way to protect and monitor your 12V battery system? ...

Build a 12V Battery Autocut System with LCD Display

Are you looking for an efficient and affordable way to protect and monitor your 12V battery system? ...

-

DIY Transistor Tester | Build Your Own LCR Meter at Home with Arduino Nano

Are you fascinated by electronics and want to create your own tools for testing components? Building...

DIY Transistor Tester | Build Your Own LCR Meter at Home with Arduino Nano

Are you fascinated by electronics and want to create your own tools for testing components? Building...

-

How to Make a Pure Sine Wave Inverter Using EG8010 + IR2110S | Step-by-Step Guide

How to Make a Pure Sine Wave Inverter Using EG8010 + IR2110S | Step-by-Step GuideIf you are looking ...

How to Make a Pure Sine Wave Inverter Using EG8010 + IR2110S | Step-by-Step Guide

How to Make a Pure Sine Wave Inverter Using EG8010 + IR2110S | Step-by-Step GuideIf you are looking ...

-

🔋 How to Make DC Changeover for Automatic Inverter System | DIY Inverter Changeover Switch

Are you tired of manually switching between DC power supply and battery backup during load shedding?...

🔋 How to Make DC Changeover for Automatic Inverter System | DIY Inverter Changeover Switch

Are you tired of manually switching between DC power supply and battery backup during load shedding?...

-

No Need Adapter 🤔 WiFi Router UPS Making with Transformer

No Need Adapter WiFi Router UPS Making with Transformer | Complete Circuit DiagramAre you tired of ...

No Need Adapter 🤔 WiFi Router UPS Making with Transformer

No Need Adapter WiFi Router UPS Making with Transformer | Complete Circuit DiagramAre you tired of ...

-

🔋 How to Make a Power Bank Module at Home

Are you looking to build your own DIY power bank at home? In this blog post, we’ll show you how to c...

🔋 How to Make a Power Bank Module at Home

Are you looking to build your own DIY power bank at home? In this blog post, we’ll show you how to c...

-

Cute LIT 220W Inverter Load Test ⚡ Auto Changeover IPS System Explained! 🔋 Real Load Backup Test

Are you looking for a reliable backup power solution for your WiFi router, CCTV, or small appliances...

Cute LIT 220W Inverter Load Test ⚡ Auto Changeover IPS System Explained! 🔋 Real Load Backup Test

Are you looking for a reliable backup power solution for your WiFi router, CCTV, or small appliances...

-

⚡ Hybrid WiFi Router UPS for Solar System

IntroductionPower cuts in off-grid areas can disrupt internet connectivity. With the rise of solar s...

⚡ Hybrid WiFi Router UPS for Solar System

IntroductionPower cuts in off-grid areas can disrupt internet connectivity. With the rise of solar s...

-

🔋 DIY Solar-Based Mini IPS at Home | Auto Load Changeover Circuit for 12V DC Fan/Light

If you're looking for an easy and affordable solution to keep your 12V DC fan or light running even ...

🔋 DIY Solar-Based Mini IPS at Home | Auto Load Changeover Circuit for 12V DC Fan/Light

If you're looking for an easy and affordable solution to keep your 12V DC fan or light running even ...

-

🔋 DIY Automatic Cut Off 12V Trickle Charger | Lead Acid Battery AutoCut Charger

Do you often charge your 12V lead-acid battery manually and worry about overcharging? With this DIY ...

🔋 DIY Automatic Cut Off 12V Trickle Charger | Lead Acid Battery AutoCut Charger

Do you often charge your 12V lead-acid battery manually and worry about overcharging? With this DIY ...

-

🔥 DIY Smart 12V Battery at Home | Using 18650 Cells + Smart BMS

Looking for a way to build a powerful and smart 12V battery at home? In this guide, I'll show you h...

🔥 DIY Smart 12V Battery at Home | Using 18650 Cells + Smart BMS

Looking for a way to build a powerful and smart 12V battery at home? In this guide, I'll show you h...

-

🎮 DIY Arduino Nano Snake Game Console with OLED Display

DIY Arduino Nano Snake Game Console with OLED Display and ButtonsDo you love retro games? Want to bu...

🎮 DIY Arduino Nano Snake Game Console with OLED Display

DIY Arduino Nano Snake Game Console with OLED Display and ButtonsDo you love retro games? Want to bu...

-

DIY 150W IPS Making At Home with Auto Changeover System | Mini IPS 2025

How to Make an Automatic 150W IPS Using Two Circuit ModulesAre you looking for a reliable and effici...

DIY 150W IPS Making At Home with Auto Changeover System | Mini IPS 2025

How to Make an Automatic 150W IPS Using Two Circuit ModulesAre you looking for a reliable and effici...

-

-

AEL-2011 Power Supply Module

553 0 2 -

AEL-2011 50W Power Amplifier

512 0 2 -

-

-

Custom Mechanical Keyboard

710 0 0 -

Tester for Touch Screen Digitizer without using microcontroller

340 2 2 -

Audio reactive glow LED wristband/bracelet with NFC / RFID-Tags

322 0 1 -

-

-