|

|

M5Stack Core2 ESP32 IoT Development Kit |

x 1 |

|

arduino IDEArduino

|

|

|

|

Neuton Tiny ML Neuton |

Recognizing MNIST-based Handwritten Digits on M5Stack Core2

Introduction

In my previous experiment, I had great fun adding handmade drawing gestures for our M5Stack Touch Screen device. Check it out if interested: https://www.hackster.io/vilaksh01/handmade-drawing-recognition-interface-as-from-my-smartphone-c9895d

Now I decided to try and see if we can achieve the same for handwritten digit recognition similar to MNIST and configure interaction with a touch interface.

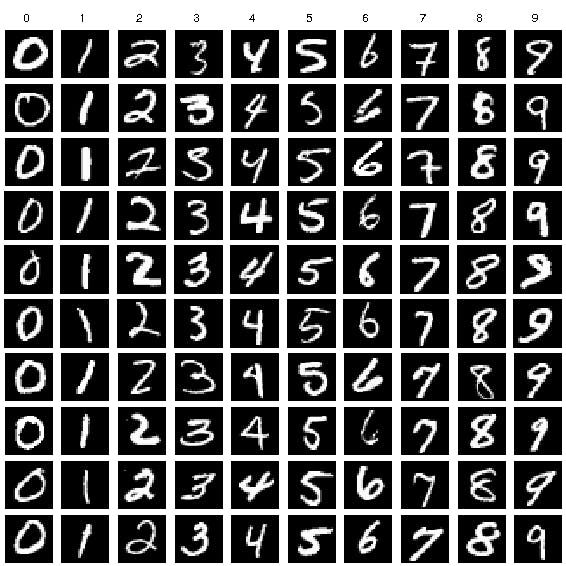

The MNIST database contains handwritten digits from 0 to 9 (60, 000 training images and 10, 000 testing images) for computer vision and machine learning projects.

MNIST is often used to solve computer vision tasks since it enables researchers to quickly check and prototype their algorithms, but I will solve this task differently using machine learning.

Most machine learning libraries (e.g.scikit-learn) and deep learning frameworks (e.g. Tensorflow, Pytorch) provide helper functions and convenient examples that use MNIST out of the box. In this project, I’ll show an easy way how to build a TinyML model with Neuton NN Framework for recognizing handwritten digits on a touch interface with simple MCUs.

Let’s get it started!

?? Step 1: Making the dataset

Like any machine learning algorithm, my network needed examples (drawing gestures) to learn from. To make the data as realistic as possible, I wrote a data collection code for inputting and maintaining a dataset of gestures on the same touch screen where the network would eventually be used.

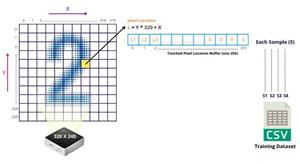

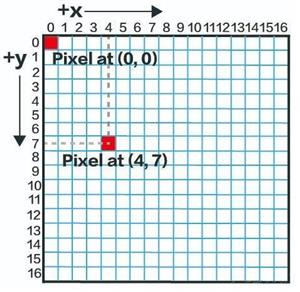

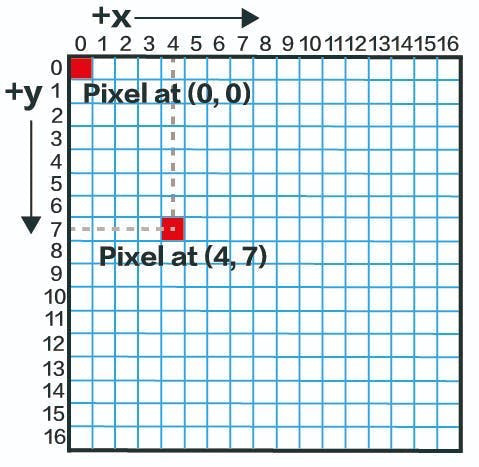

To understand the dataset collection, we will need some knowledge of pixels. In simple terms, a pixel can be identified by a pair of integers providing the column number and the row number. In our case, we are using M5Stack Core2 which has a TFT 2" Touchscreen with a resolution of 320 X 240 pixels.

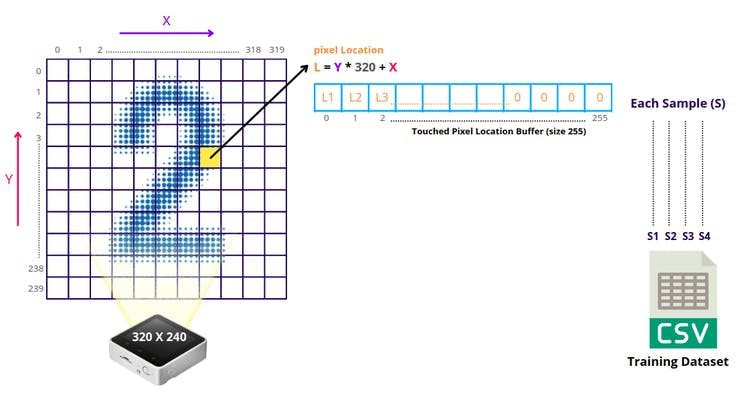

? Converting touch points on the TFT Touch screen to images then rasterizing would be complex to understand and do on our MCU, so I took another approach. Since Neural Networks are very excellent at pattern recognition, why not feed pixel locations per drawn sample and see how it performs? That’s the power of Machine Learning in action when you want to skip the implementation of your own algorithms on your data :)

The image below vividly demonstrates how it works. The code for the data collection is available in the code section.

The buffer size is fixed to 255 since I found out that at any point in time the number of touched pixels while drawing digits or symbols never exceeded 255 in total.

I collected 100 samples for each gesture [1, 2, 3, 4,5,6,7,8,9,0]. Once your dataset is collected, it will look like this:

The collected dataset is similar to MNIST, and we have almost the same model accuracy on the dataset of smaller size and our model is very compact. The models for the same cases in the examples below have hundreds of thousands to millions of coefficients, which makes them undeployable on MCUs:

- https://www.kaggle.com/code/dkurbatovv/digit-recognizer-0-998

- https://www.kaggle.com/code/kimchanyoung/mnist-classifier-baseline-for-starter-99-4

- https://www.kaggle.com/code/hhp07022000/digit-recognizer-using-tensorflow

?? Step 2: Training the model

To train my model, I use the Neuton TinyML platform because it eliminates the need to set parameters for the NN architecture or apply any compression techniques.

I used to leverage TF in some of my previous projects, but now I switched to Neuton since it’s free and doesn’t require a lot of iterations. It’s enough to upload a CSV dataset to get a very compact model, ready for deployment on low-power MCUs without additional compression.

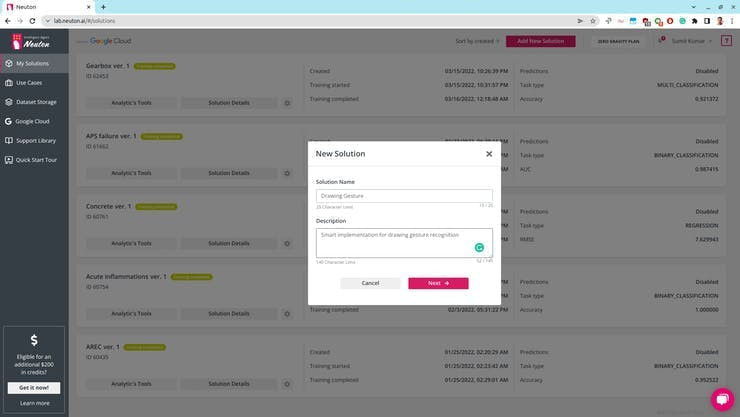

First, I create a new solution on the Neuton Platform (https://neuton.ai) and upload my dataset.

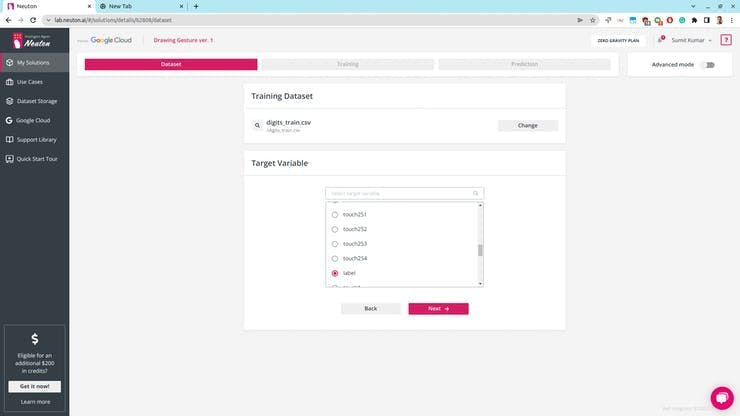

I select the target variable. In our case, it is the label.

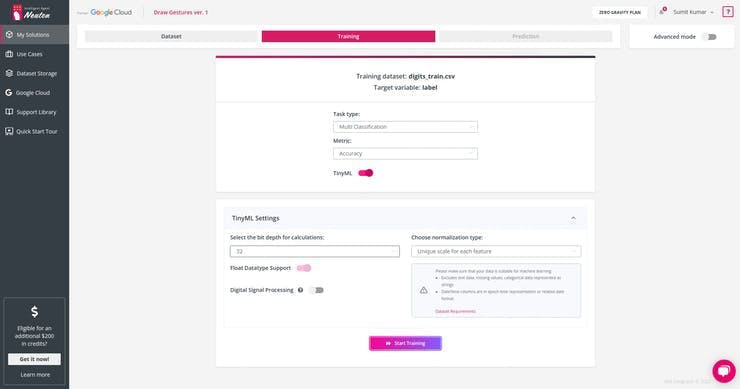

Next, I set the TinyML model training parameters as shown below and start the training.

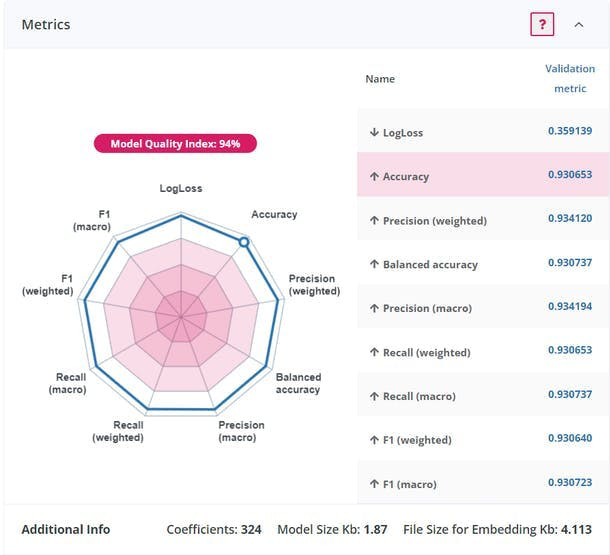

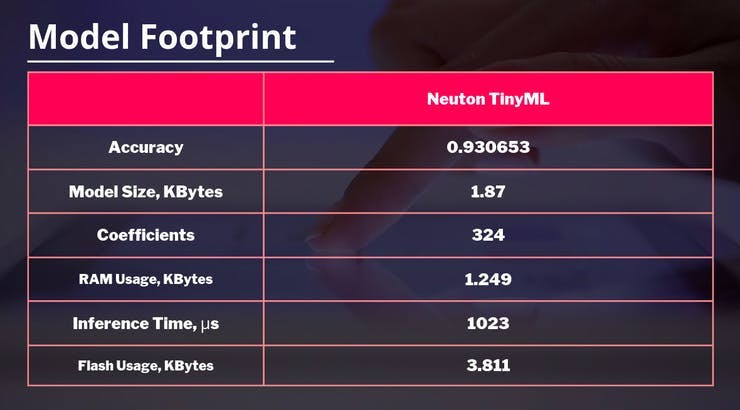

Once the training is complete, you can check the analytics below and model accuracy. In my case, accuracy was about 93.0653%.With only 324 coefficients and only 4.113 KB embedding size, that's really freaking awesome!

And finally, I download the model for embedding into the M5Stack Core2 device.

Step 3: Embedding on the device

After the model is downloaded, I extract it and put the model in the same folder where the main Arduino code file is located.

. ├── DigitRecognition.ino ├── model │ └── model.h ├── neuton.c ├── neuton.h ├── README.md ├── StatFunctions.c └── StatFunctions.h

The important functions here are, neuton_model_set_inputs – to set input values, neuton_model_run_inference – to make predictions. Check the full source code in the code section.

// counter threshold ensures that the buffer is not empty or any accidental screen touch/taps

if (neuton_model_set_inputs(inputBuff) == 0 && counter > 5)

{

uint16_t index;

float* outputs;

if (neuton_model_run_inference(&index, &outputs) == 0)

{

// code for handling prediction result

// Serial.println("Prediction: " + String(index));

if (index == 0)

{

Serial.println("0");

}

if (index == 1)

{

Serial.println("1");

}

if (index == 2)

{

Serial.println("2");

}

if (index == 3)

{

Serial.println("3");

}

if (index == 4)

{

Serial.println("4");

}

if (index == 5)

{

Serial.println("5");

}

if (index == 6)

{

Serial.println("6");

}

if (index == 7)

{

Serial.println("7");

}

if (index == 8)

{

Serial.println("8");

}

if (index == 9)

{

Serial.println("9");

}

}

}

counter = 0;

prev = 0;

neuton_model_reset_inputs();

free(inputBuff); // free the memory

inputBuff = (float*) calloc(touchBufferSize, sizeof(float));

if (!inputBuff)

{

Serial.println("Failed to allocate memory");

}

See how the model works on the device:

Conclusion

This tutorial clearly explains how to use the TinyML capabilities on MCU when traditional algorithms are too slow or produce huge models that can’t be deployed to low-power MCUs.

Please share your feedback, especially if you decide to repeat this experiment yourself, in the comments below :)

Recognizing MNIST-based Handwritten Digits on M5Stack Core2

- Comments(0)

- Likes(1)

-

vilaksh01

May 05,2022

vilaksh01

May 05,2022

- 0 USER VOTES

- YOUR VOTE 0.00 0.00

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

More by vilaksh01

More by vilaksh01

-

Predictive Maintenance Of Compressor Water Pumps

An ordinary resident of a metropolis rarely thinks about how water enters taps or central heating pi...

Predictive Maintenance Of Compressor Water Pumps

An ordinary resident of a metropolis rarely thinks about how water enters taps or central heating pi...

-

Unlock Passwords With Tinyml-based Digit Recognition

Story? IntroductionThe active development of smart gadgets with touch interfaces is trending nowaday...

Unlock Passwords With Tinyml-based Digit Recognition

Story? IntroductionThe active development of smart gadgets with touch interfaces is trending nowaday...

-

Handmade Drawing Recognition Interface As From My Smartphone

StoryIntroductionI was inspired by such features on our smartphones. My smartphone “Vivo V7” has a f...

Handmade Drawing Recognition Interface As From My Smartphone

StoryIntroductionI was inspired by such features on our smartphones. My smartphone “Vivo V7” has a f...

-

Recognizing MNIST-based Handwritten Digits on M5Stack Core2

IntroductionIn my previous experiment, I had great fun adding handmade drawing gestures for our M5St...

Recognizing MNIST-based Handwritten Digits on M5Stack Core2

IntroductionIn my previous experiment, I had great fun adding handmade drawing gestures for our M5St...

-

Tuya Link SDK IoT Smart Environment Sensing And Humidifier

IntroductionI had been exploring the Tuya IoT platform for the past few months and they never fail t...

Tuya Link SDK IoT Smart Environment Sensing And Humidifier

IntroductionI had been exploring the Tuya IoT platform for the past few months and they never fail t...

-

Tuya IoT Cloud Smart Weather Lamp

IntroductionHello everybody, ever felt like having a smart home device to visually show/signal you t...

Tuya IoT Cloud Smart Weather Lamp

IntroductionHello everybody, ever felt like having a smart home device to visually show/signal you t...

-

Getting Started With Arduino IoT Control With Tuya

Introduction:I have always enjoyed using Arduino UNO since it was my first programmable board but it...

Getting Started With Arduino IoT Control With Tuya

Introduction:I have always enjoyed using Arduino UNO since it was my first programmable board but it...

-

Coronavirus - India cases tracker

Today everyone is gazing at their phone to keep track of the coronavirus in their country but we ten...

Coronavirus - India cases tracker

Today everyone is gazing at their phone to keep track of the coronavirus in their country but we ten...

-

CliSensio - Climate Sensing and Insect Infestation Control

Overview:Climate Change, is a highly debated high school topic, but do we really care about it? We s...

CliSensio - Climate Sensing and Insect Infestation Control

Overview:Climate Change, is a highly debated high school topic, but do we really care about it? We s...

-

AI For truck APS Failure Detection on a $4 MCU

IntroductionThe automotive industry is among the pioneers to adopt cutting-edge technologies, machin...

AI For truck APS Failure Detection on a $4 MCU

IntroductionThe automotive industry is among the pioneers to adopt cutting-edge technologies, machin...

-

New Era Farming with TensorFlow on Lowest Power Consumption

Overview:This project demonstrates how to build a device using TensorFlow and Artemis module to solv...

New Era Farming with TensorFlow on Lowest Power Consumption

Overview:This project demonstrates how to build a device using TensorFlow and Artemis module to solv...

-

TinyML Gearbox Fault Prediction on a $4 MCU

StoryIs it possible to make an AI-driven system that predicts gearbox failure on a simple $4 MCU? Ho...

TinyML Gearbox Fault Prediction on a $4 MCU

StoryIs it possible to make an AI-driven system that predicts gearbox failure on a simple $4 MCU? Ho...

-

AREC - Agricultural Records On Electronic Contracts

Objective:One of the biggest reasons behind the growth of fake products in the agrochemical industry...

AREC - Agricultural Records On Electronic Contracts

Objective:One of the biggest reasons behind the growth of fake products in the agrochemical industry...

-

AquaMon - Aquaponics and Fish Tank Monitoring with Tuya IoT

IntroductionDo you love sea creatures? I don't think I would find a single person who would not fall...

AquaMon - Aquaponics and Fish Tank Monitoring with Tuya IoT

IntroductionDo you love sea creatures? I don't think I would find a single person who would not fall...

-

-

AEL-2011 Power Supply Module

525 0 2 -

AEL-2011 50W Power Amplifier

485 0 2 -

-

-

Custom Mechanical Keyboard

693 0 0 -

Tester for Touch Screen Digitizer without using microcontroller

330 2 2 -

Audio reactive glow LED wristband/bracelet with NFC / RFID-Tags

310 0 1 -

-

-