|

Raspberry Pi Pico |

x 1 |

|

|

Neuton Tiny Machine Learning - Automatically build extremely tiny and explainable modelsNeuton AI

|

|

|

arduino IDEArduino

|

AI For truck APS Failure Detection on a $4 MCU

Introduction

The automotive industry is among the pioneers to adopt cutting-edge technologies, machine learning is no exception. With the help of ML solutions, engineers can now build neural networks to detect various car defects and breakages. In this article, I’d like to showcase how practitioners can easily apply the TinyML methodologies to create and deploy an AI-based solution on a primitive tiny device to predict truck failure related to the Air Pressure System (APS).

Being an essential part of a heavy-duty vehicle, APS generates pressurized air that is utilized in various functions in a truck, such as braking and gear changes, so timely failure detection can reduce the downtimes and the overall money spent in breakdowns up to a certain extent, as well as ease the process of truck inspections for drivers and employees, making it less error-prone.

Business Constraint

Latency: The time taken to make predictions after getting the data must be fairly low to avoid any unnecessary increase in the maintenance time and cost.

Cost of device: Having heavy GPUs, and expensive edge devices would add unnecessary maintenance costs. Instead, the focus should be on better sensors and custom AutoML/TinyML solutions with higher accuracy and low memory footprints.

Cost of misclassification: The cost of misclassification is very high, especially if wrongly classifying a positive class datapoint, as it can lead to a complete breakdown of the truck and incur some serious costs.

Technologies Used

Neuton TinyML: Neuton is a no-code platform based on a patented neural network framework. I selected this solution for my experiment since it is free to use and automatically creates tiny machine learning models deployable even on 8-bit MCUs. According to Neuton developers, you can create a compact model in one iteration without compression.

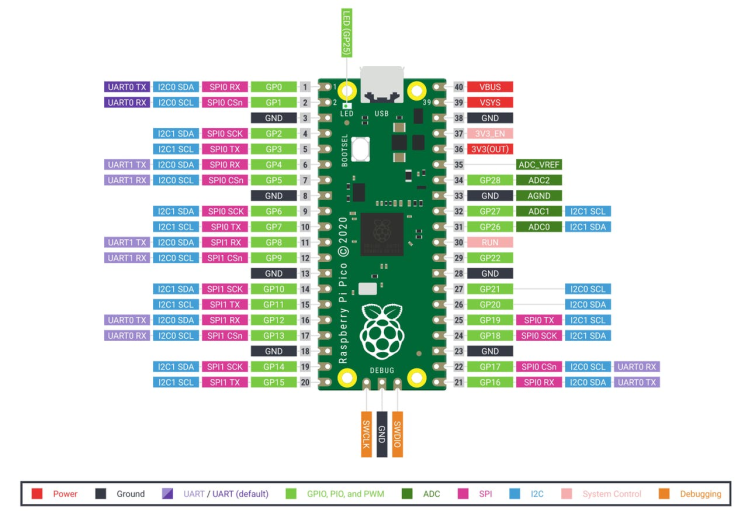

Raspberry Pi Pico: The chip employs two ARM Cortex-M0 + cores, 133 megahertz, which are also paired with 256 kilobytes of RAM when mounted on the chip. The device supports up to 16 megabytes of off-chip flash storage, has a DMA controller, and includes two UARTs and two SPIs, as well as two I2C and one USB 1.1 controller. The device received 16 PWM channels and 30 GPIO needles, four of which are suitable for analog data input. And with a net $ 4 price tag.

Let's Build It

The goal of this tutorial is to demonstrate how you can easily build a compact ML model to solve a binary classification task in which the positive class means that the problem in the truck is due to a fault in the APS while the negative class means otherwise.

In our case, we utilize the dataset made using readings taken from Scania Trucks in their daily use (collected and provided by Scania themselves). The names of all the features are anonymized due to proprietary reasons. The dataset for this case study can be found here: https://archive.ics.uci.edu/ml/datasets/APS+Failure+at+Scania+Trucks

The experiment will be conducted on a $4 MCU, with no cloud computing carbon footprints :)

Dataset Description

The dataset is divided into two parts, a train set, and a test set. The train set contains 60, 000 rows while the test set contains 16, 000 rows. There are 171 columns in the dataset, one of them is the class label of the datapoint, resulting in 170 features for each data point.

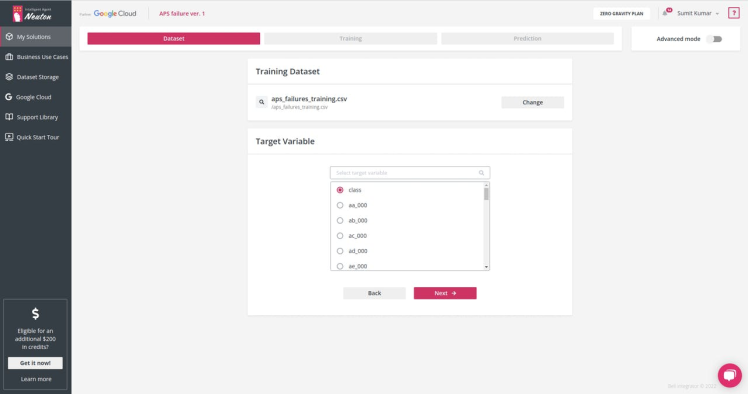

Step 1: Creating a New Solution and Uploading the Dataset on the Neuton TinyML Platform

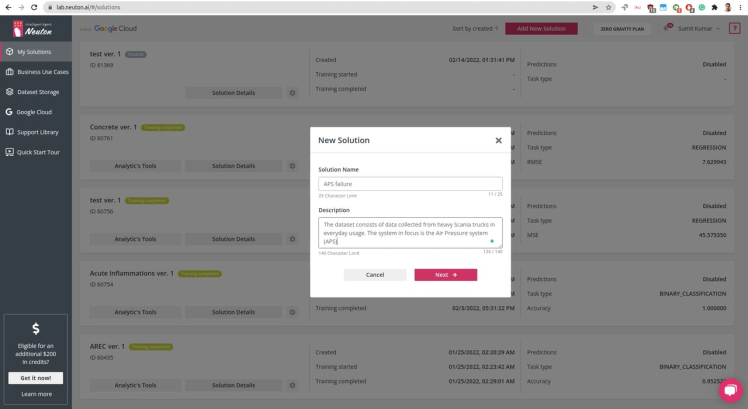

Once you are signed in to your Neuton account, you should have a Solutions Home page, click on Add New Solution button.

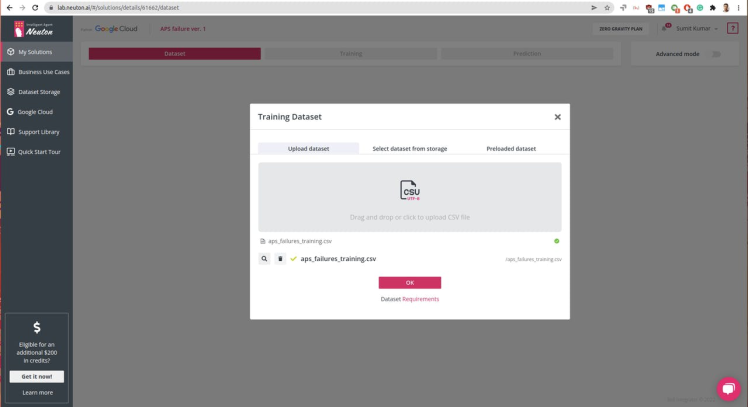

Once the solution is created, as shown above, proceed to dataset uploading (keep in mind that the currently supported format is CSV only).

Select the target variable or the output you want for each prediction. In this case, we have class as Output Variable: 0 for 'negative' and 1 for 'positive'

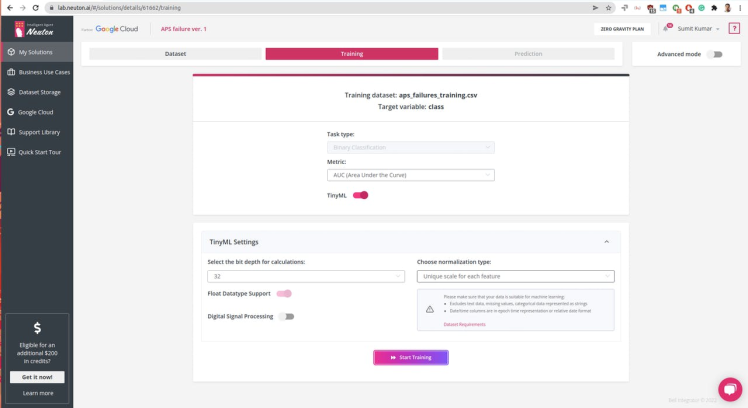

Step 2: Model Training and Parameters

Since we are going to embed the model onto a tiny MCU, we need to set the parameters accordingly. The Raspberry Pico can run 32-bit operations and set normalization type to Unique Scale for Each Feature

Click start training, it might take longer to train since the dataset is huge, for me, it took about ~6 hours. In the meantime, you can check out Exploratory Data Analysis generated once the data processing is complete, check the below video:

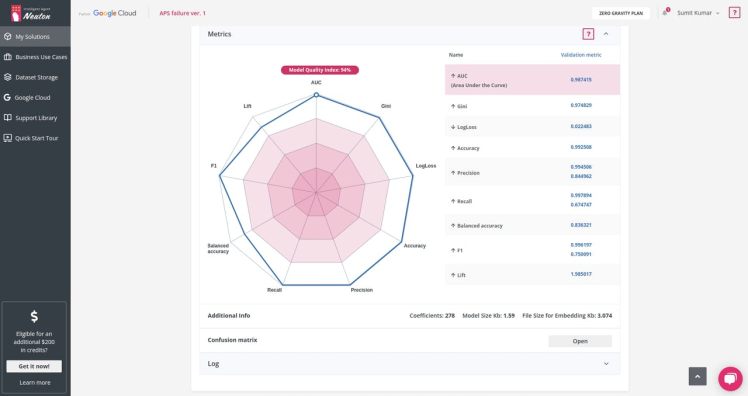

During training, you can monitor the real-time model performance by observing model status (“consistent” or “not consistent”) and Target metric value.

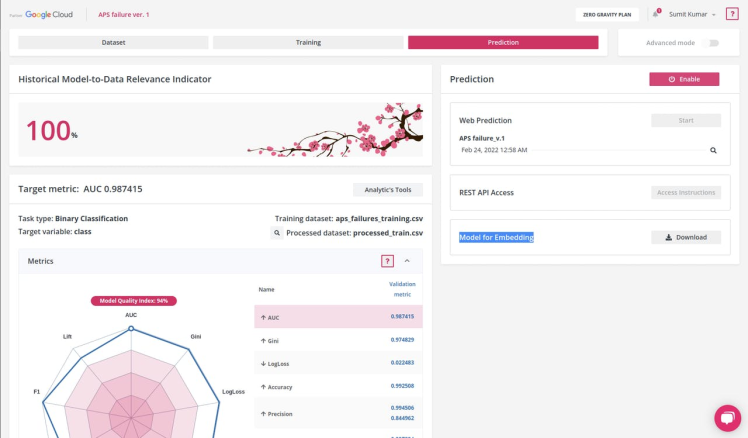

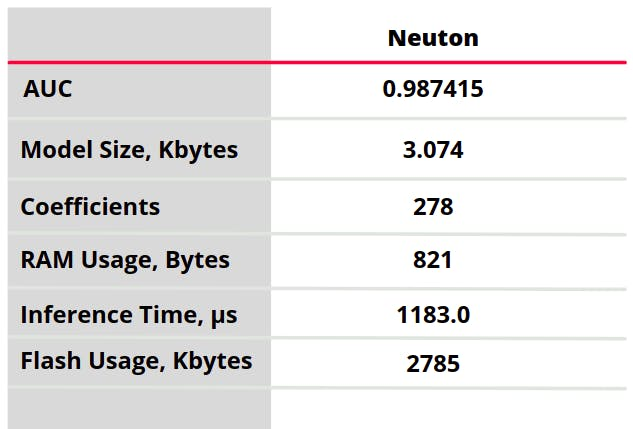

The target metric for me was: AUC 0.987415 and the trained model had the following characteristics:

Number of coefficients = 278, File Size for Embedding = 3.074 Kb. That's super cool!

Step 3: Prediction and Embedding on Raspberry Pico

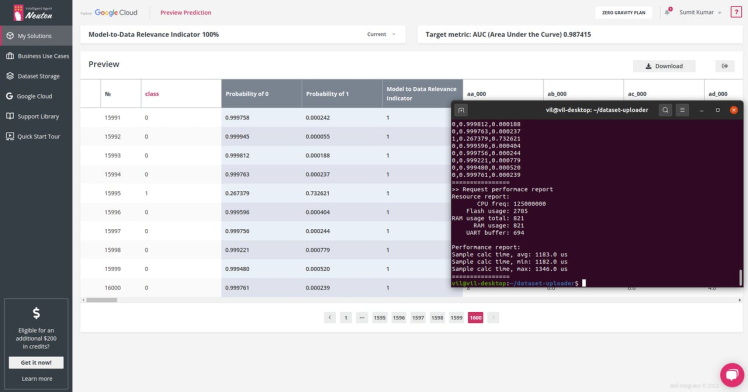

On the Neuton ai platform, click on the Prediction tab, and click on the Download button next to Model for Embedding, this would be the model library file that we are going to use for our device.

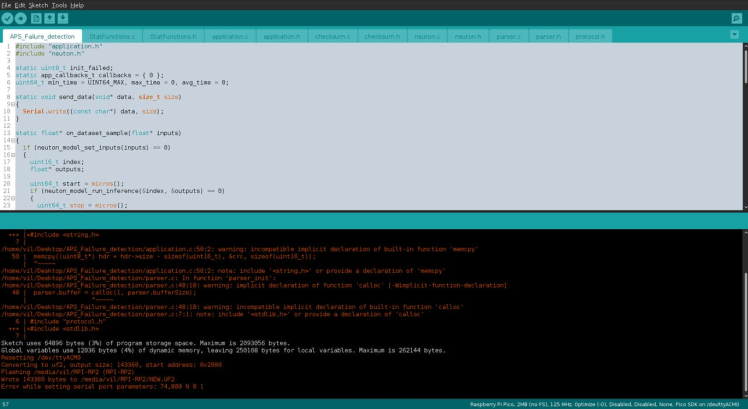

Once you have downloaded the model files, it's time to add our custom functions and actions. I am using Arduino IDE to program Raspberry Pico

Setting up Arduino IDE for Raspberry Pico:

I used Ubuntu for this tutorial, but the exact instructions should work for other Debian based distributions such as Raspberry Pi OS.

1. Open a terminal and use wget to download the official Pico setup script.

$ wget https://raw.githubusercontent.com/raspberrypi/pico-setup/master/pico_setup.sh

2. In the same terminal modify the downloaded file to be executable.

$ chmod +x pico_setup.sh

3. Run pico_setup.sh to start the installation process. Enter your sudo password if prompted.

$ ./pico_setup.sh

4. Download the Arduino IDEand install it on your machine.

5. Open a terminal and add your user to the group “dialout.” This group can communicate with devices such as the Arduino. Using “$USER” will automatically use your username.

$ sudo usermod -a -G dialout “$USER”

6. Log out or reboot your computer for the changes to take effect.

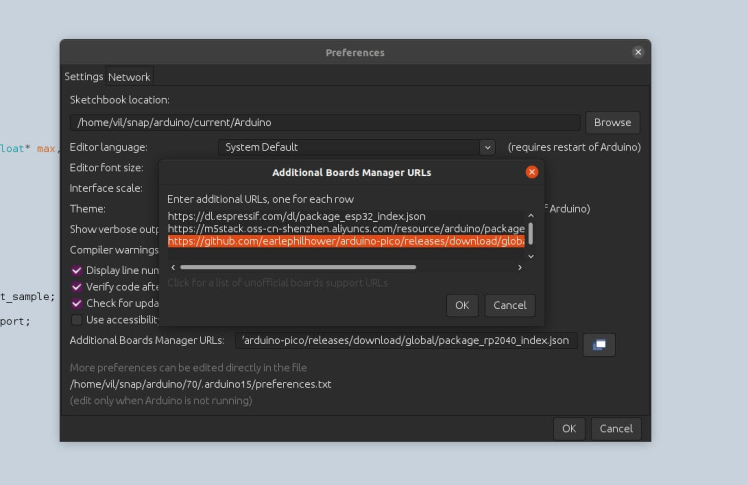

7. Open the Arduino application and go to File >> Preferences.

8. In the additional boards' manager add this line and click OK.

https://github.com/earlephilhower/arduino-pico/releases/download/global/package_rp2040_index.json

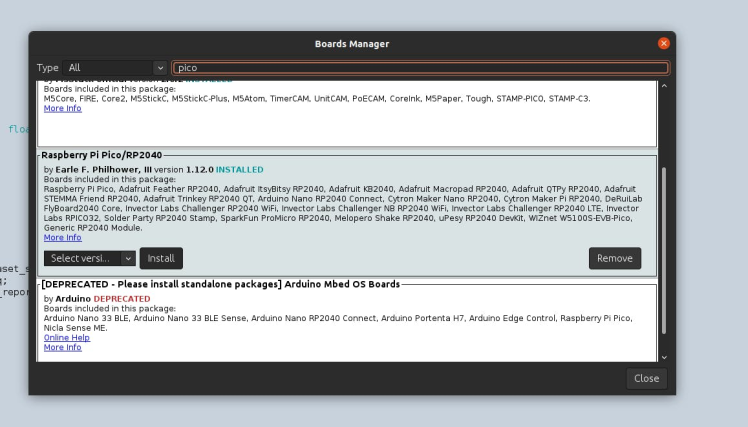

9. Go to Tools >> Board >> Boards Manager.

10. Type “pico” in the search box and then install the Raspberry Pi Pico / RP2040 board. This will trigger another large download, approximately 300MB in size.

Note: Since we are going to make classification on the test dataset, we will use the CSV utility provided by Neuton to run inference on data sent to the MCU via USB.

Here is our project directory,

user@desktop:~/Desktop/APS_Failure_detection$ tree

.

├── application.c

├── application.h

├── APS_Failure_detection.ino

├── checksum.c

├── checksum.h

├── model

│ └── model.h

├── neuton.c

├── neuton.h

├── parser.c

├── parser.h

├── protocol.h

├── StatFunctions.c

└── StatFunctions.h

1 directory, 13 files

Checksum, parser program files are for generating handshake with the CSV serial utility tool and sending column data to the Raspberry Pico for inference.

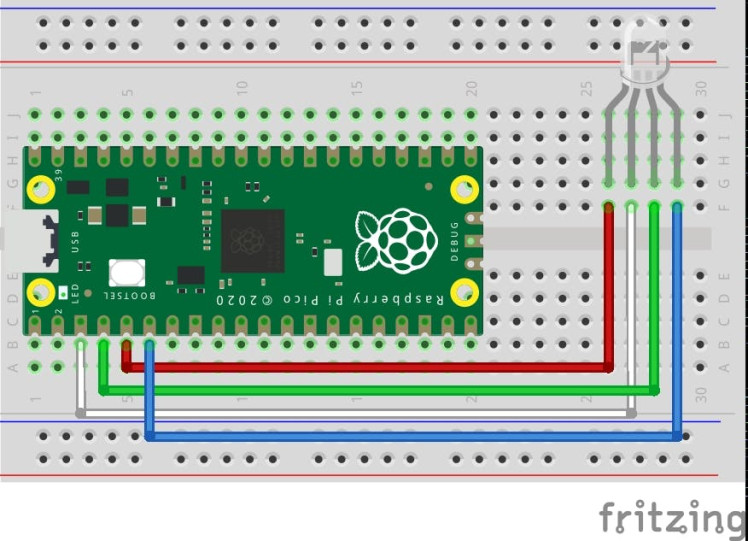

[Secrettip: If you train a similar binary classification model, just replace the model.h file and modify the *.ino file accordingly to run running inference on the CSV dataset via USB serial] See pin connection below

Understanding the code part in APS_Failure_detection.ino file, we set different callbacks for monitoring CPU, time, and memory usage used while inferencing.

void setup() {

Serial.begin(230400);

while (!Serial);

pinMode(LED_RED, OUTPUT);

pinMode(LED_BLUE, OUTPUT);

pinMode(LED_GREEN, OUTPUT);

digitalWrite(LED_RED, LOW);

digitalWrite(LED_BLUE, LOW);

digitalWrite(LED_GREEN, LOW);

callbacks.send_data = send_data;

callbacks.on_dataset_sample = on_dataset_sample;

callbacks.get_cpu_freq = get_cpu_freq;

callbacks.get_time_report = get_time_report;

init_failed = app_init(&callbacks);

}

The real magic happens here callbacks.on_dataset_sample=on_dataset_sample

static float* on_dataset_sample(float* inputs)

{

if (neuton_model_set_inputs(inputs) == 0)

{

uint16_t index;

float* outputs;

uint64_t start = micros();

if (neuton_model_run_inference(&index, &outputs) == 0)

{

uint64_t stop = micros();

uint64_t inference_time = stop - start;

if (inference_time > max_time)

max_time = inference_time;

if (inference_time < min_time)

min_time = inference_time;

static uint64_t nInferences = 0;

if (nInferences++ == 0)

{

avg_time = inference_time;

}

else

{

avg_time = (avg_time * nInferences + inference_time) / (nInferences + 1);

}

// add your functions to respond to events based upon detectionswitch (index)

{

case 0:

//Serial.println("0: No Failure");

digitalWrite(LED_GREEN, HIGH);

break;

case 1:

//Serial.println("1: APS Failure Detected");

digitalWrite(LED_RED, HIGH);

break;

case 2:

//Serial.println("2: Unknown");

digitalWrite(LED_BLUE, HIGH);

break;

default:

break;

}

return outputs;

}

}

return NULL;

}

Once the input variables are ready, neuton_model_run_inference(&index, &outputs) is called which runs inference and returns outputs.

Installing CSV dataset Uploading Utility (Currently works on Linux and macOS only)

Install dependencies,

# For Ubuntu

$ sudo apt install libuv1-dev gengetopt

# For macOS

$ brew install libuv gengetopt

Clone this repo,

$ git clone https://github.com/Neuton-tinyML/dataset-uploader.git

$ cd dataset-uploader

Run make to build the binaries,

$ make

Once it's done, you can try running the help command, it's should be similar to that shown below

user@desktop:~/dataset-uploader$ ./uploader -h

Usage: uploader [OPTION]...

Tool for upload CSV file MCU

-h, --help Print help and exit

-V, --version Print version and exit

-i, --interface=STRING interface (possible values="udp", "serial"default=`serial')

-d, --dataset=STRING Dataset file (default=`./dataset.csv')

-l, --listen-port=INT Listen port (default=`50000')

-p, --send-port=INT Send port (default=`50005')

-s, --serial-port=STRING Serial port device (default=`/dev/ttyACM0')

-b, --baud-rate=INT Baud rate (possible values="9600", "115200",

"230400" default=`230400')

--pause=INT Pause before start (default=`0')

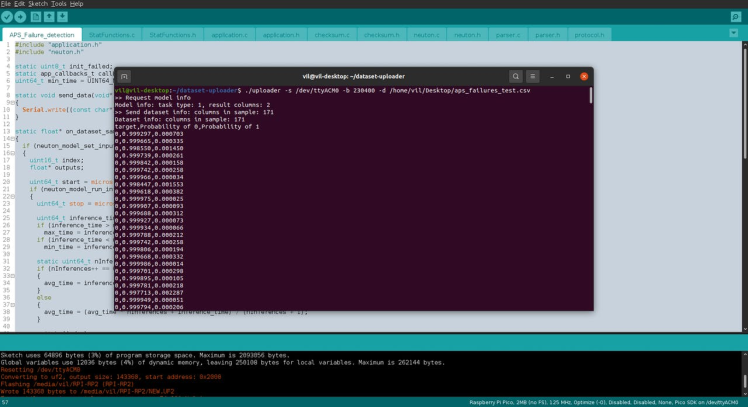

Step 4: Running inference on Raspberry Pico

Upload the program on the Raspberry Pico,

Once uploaded and running, open a new terminal and run this command:

$ ./uploader -s /dev/ttyACM0 -b 230400 -d /home/vil/Desktop/aps_failures_test.csv

Green Light means no APS failure, Red Light means APS failure based upon the CSV test dataset received via Serial.

Green Light means no APS failure, Red Light means APS failure based upon the CSV test dataset received via Serial.

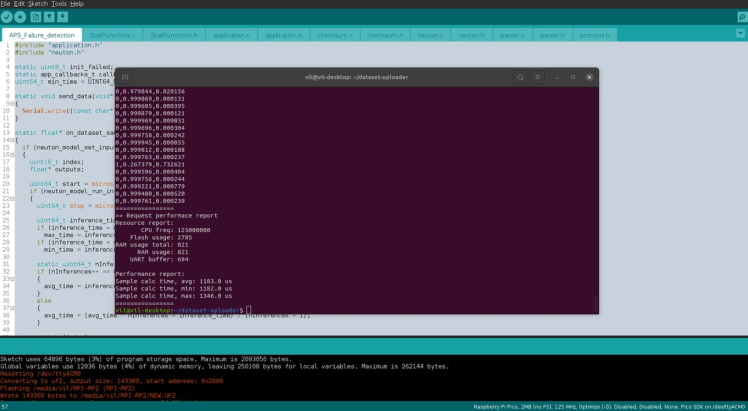

The inference has started running, once it is completed for the whole CSV dataset it will print a full summary.

>> Request performance report

Resource report:

CPU freq: 125000000

Flash usage: 2785

RAM usage total: 821

RAM usage: 821

UART buffer: 694

Performance report:

Sample calc time, avg: 1183.0 us

Sample calc time, min: 1182.0 us

Sample calc time, max: 1346.0 us

I also did a comparison with Web Prediction on the Neuton TinyML platform and the results were similar. Plus, I tried to build the same model with TensorFlow and TensorFlow Lite. My model built with Neuton TinyML turned out to be 14.3% better in terms of AUC and 9.7 times smaller in terms of model size than the one built with TF Lite. Speaking of the number of coefficients, TensorFlow's model has 7, 060 coefficients, while Neuton's model has only 278 coefficients (which is 25.4 times smaller!).

So, the resultant model footprint and inference time are as follows:

Isn't it amazing that Raspberry Pico is able to perform tasks that are otherwise handled using high-performance machines on the cloud?

Conclusion

This tutorial is vivid proof that you don’t need to be a data scientist to rapidly build super compact ML models to proactively solve practical challenges. And, most importantly, the implementation of such solutions using tinyML saves lots of money and resources and doesn’t require high costs or efforts, but only a free no-code tool and a super cheap MCU!

AI For truck APS Failure Detection on a $4 MCU

- Comments(0)

- Likes(2)

-

Engineer

Oct 23,2025

Engineer

Oct 23,2025

-

Electronic Adam

Oct 12,2025

Electronic Adam

Oct 12,2025

- 0 USER VOTES

- YOUR VOTE 0.00 0.00

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

More by vilaksh01

More by vilaksh01

-

Predictive Maintenance Of Compressor Water Pumps

An ordinary resident of a metropolis rarely thinks about how water enters taps or central heating pi...

Predictive Maintenance Of Compressor Water Pumps

An ordinary resident of a metropolis rarely thinks about how water enters taps or central heating pi...

-

Unlock Passwords With Tinyml-based Digit Recognition

Story? IntroductionThe active development of smart gadgets with touch interfaces is trending nowaday...

Unlock Passwords With Tinyml-based Digit Recognition

Story? IntroductionThe active development of smart gadgets with touch interfaces is trending nowaday...

-

Handmade Drawing Recognition Interface As From My Smartphone

StoryIntroductionI was inspired by such features on our smartphones. My smartphone “Vivo V7” has a f...

Handmade Drawing Recognition Interface As From My Smartphone

StoryIntroductionI was inspired by such features on our smartphones. My smartphone “Vivo V7” has a f...

-

Recognizing MNIST-based Handwritten Digits on M5Stack Core2

IntroductionIn my previous experiment, I had great fun adding handmade drawing gestures for our M5St...

Recognizing MNIST-based Handwritten Digits on M5Stack Core2

IntroductionIn my previous experiment, I had great fun adding handmade drawing gestures for our M5St...

-

Tuya Link SDK IoT Smart Environment Sensing And Humidifier

IntroductionI had been exploring the Tuya IoT platform for the past few months and they never fail t...

Tuya Link SDK IoT Smart Environment Sensing And Humidifier

IntroductionI had been exploring the Tuya IoT platform for the past few months and they never fail t...

-

Tuya IoT Cloud Smart Weather Lamp

IntroductionHello everybody, ever felt like having a smart home device to visually show/signal you t...

Tuya IoT Cloud Smart Weather Lamp

IntroductionHello everybody, ever felt like having a smart home device to visually show/signal you t...

-

Getting Started With Arduino IoT Control With Tuya

Introduction:I have always enjoyed using Arduino UNO since it was my first programmable board but it...

Getting Started With Arduino IoT Control With Tuya

Introduction:I have always enjoyed using Arduino UNO since it was my first programmable board but it...

-

Coronavirus - India cases tracker

Today everyone is gazing at their phone to keep track of the coronavirus in their country but we ten...

Coronavirus - India cases tracker

Today everyone is gazing at their phone to keep track of the coronavirus in their country but we ten...

-

CliSensio - Climate Sensing and Insect Infestation Control

Overview:Climate Change, is a highly debated high school topic, but do we really care about it? We s...

CliSensio - Climate Sensing and Insect Infestation Control

Overview:Climate Change, is a highly debated high school topic, but do we really care about it? We s...

-

AI For truck APS Failure Detection on a $4 MCU

IntroductionThe automotive industry is among the pioneers to adopt cutting-edge technologies, machin...

AI For truck APS Failure Detection on a $4 MCU

IntroductionThe automotive industry is among the pioneers to adopt cutting-edge technologies, machin...

-

New Era Farming with TensorFlow on Lowest Power Consumption

Overview:This project demonstrates how to build a device using TensorFlow and Artemis module to solv...

New Era Farming with TensorFlow on Lowest Power Consumption

Overview:This project demonstrates how to build a device using TensorFlow and Artemis module to solv...

-

TinyML Gearbox Fault Prediction on a $4 MCU

StoryIs it possible to make an AI-driven system that predicts gearbox failure on a simple $4 MCU? Ho...

TinyML Gearbox Fault Prediction on a $4 MCU

StoryIs it possible to make an AI-driven system that predicts gearbox failure on a simple $4 MCU? Ho...

-

AREC - Agricultural Records On Electronic Contracts

Objective:One of the biggest reasons behind the growth of fake products in the agrochemical industry...

AREC - Agricultural Records On Electronic Contracts

Objective:One of the biggest reasons behind the growth of fake products in the agrochemical industry...

-

AquaMon - Aquaponics and Fish Tank Monitoring with Tuya IoT

IntroductionDo you love sea creatures? I don't think I would find a single person who would not fall...

AquaMon - Aquaponics and Fish Tank Monitoring with Tuya IoT

IntroductionDo you love sea creatures? I don't think I would find a single person who would not fall...

-

-

mammoth-3D SLM Voron Toolhead – Manual Drill & Tap Edition

223 0 0 -

-

AEL-2011 Power Supply Module

746 0 2 -

AEL-2011 50W Power Amplifier

620 0 2 -

-

-

Custom Mechanical Keyboard

816 0 0 -

Tester for Touch Screen Digitizer without using microcontroller

446 2 2 -

Audio reactive glow LED wristband/bracelet with NFC / RFID-Tags

397 0 1 -

-