|

Raspberry Pi Pico |

x 1 |

|

|

Neuton Tiny ML Neuton - Automatically build extremely tiny and explainable models without any codingNeuon AI

|

|

|

arduino IDEArduino

|

TinyML Gearbox Fault Prediction on a $4 MCU

Story

Is it possible to make an AI-driven system that predicts gearbox failure on a simple $4 MCU? How to automatically build a compact model that does not require any additional compression? Can a non-data scientist implement such projects successfully?

I will answer all these questions in my new project.

Introduction and Business Constraint

In industry (e.g., wind power, automotive), gearboxes often operate under random speed variations. A condition monitoring system is expected to detect faults, and broken tooth conditions and assess their severity using vibration signals collected under different speed profiles.

Modern cars have hundreds of thousands of details and systems where it is necessary to predict breakdowns, control the state of temperature, pressure, etc. As such, in the automotive industry, it is critically important to create and embed TinyML models that can perform right on the sensors and open up a set of technological advantages, such as:

- Internet independence

- No waste of energy and money on data transfer

- Advanced privacy and security

In my experiment, I want to show how to easily create such a technology prototype to popularize the TinyML approach and use its incredible capabilities for the automotive industry.

Technologies Used

- Neuton TinyML: Neuton, I selected this solution since it is free to use and automatically creates tiny machine learning models deployable even on 8-bit MCUs. According to Neuton developers, you can create a compact model in one iteration without compression.

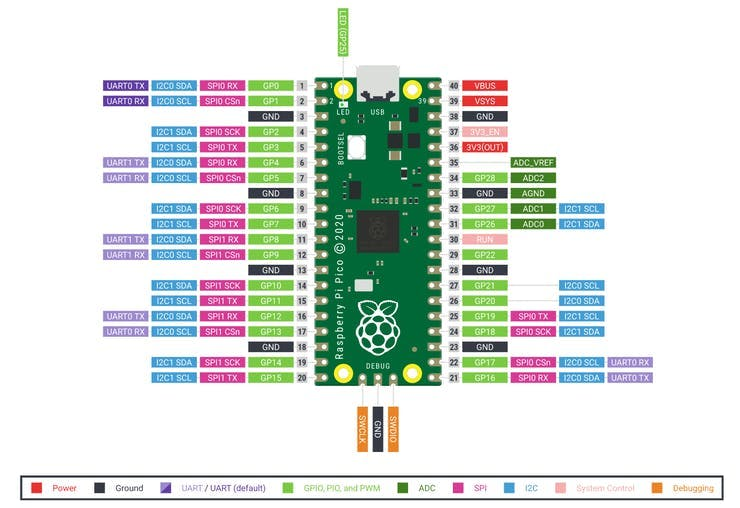

- Raspberry Pi Pico: The chip employs two ARM Cortex-M0 + cores, 133 megahertz, which are also paired with 256 kilobytes of RAM when mounted on the chip. The device supports up to 16 megabytes of off-chip flash storage, has a DMA controller, and includes two UARTs and two SPIs, as well as two I2C and one USB 1.1 controller. The device received 16 PWM channels and 30 GPIO needles, four of which are suitable for analog data input. And with a net $4 price tag.

Let's Build It

The goal of this tutorial is to demonstrate how you can easily build a compact ML model to solve a multi-class classification task to detect broken tooth conditions in the gearbox.

Dataset Description

Gearbox Fault Diagnosis Dataset includes the vibration dataset recorded by using SpectraQuest’s Gearbox Fault Diagnostics Simulator.

Dataset has been recorded using 4 vibration sensors placed in four different directions and under variation of load from '0' to '90' per cent. Two different scenarios are included: 1) Healthy condition 2) Broken tooth condition

There are 20 files in total, 10 for a healthy gearbox and 10 for a broken one. Each file corresponds to a given load from 0% to 90% in steps of 10%. You can find this dataset through the link: https://www.kaggle.com/datasets/brjapon/gearbox-fault-diagnosis

The experiment will be conducted on a $4 MCU, with no cloud computing carbon footprints :)

Step 1: Model training

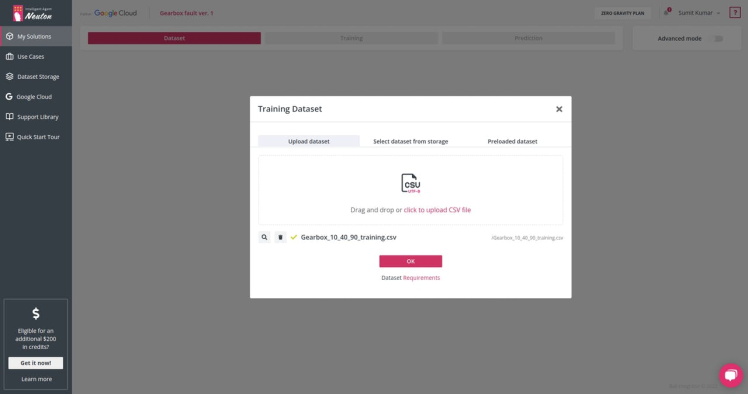

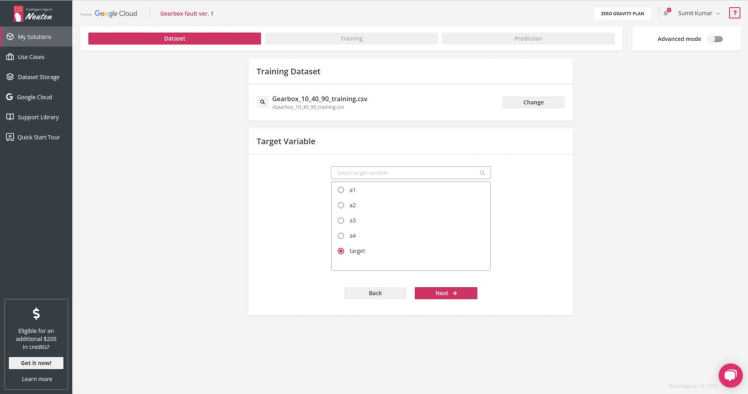

For model training, I'll use the free of charge platform, Neuton TinyML. Once the solution is created, proceed to the dataset uploading (keep in mind that the currently supported format is CSV only).

It's time to select the target variable or the output you want for each prediction. In this case, we have class as Output Variable: 'target'

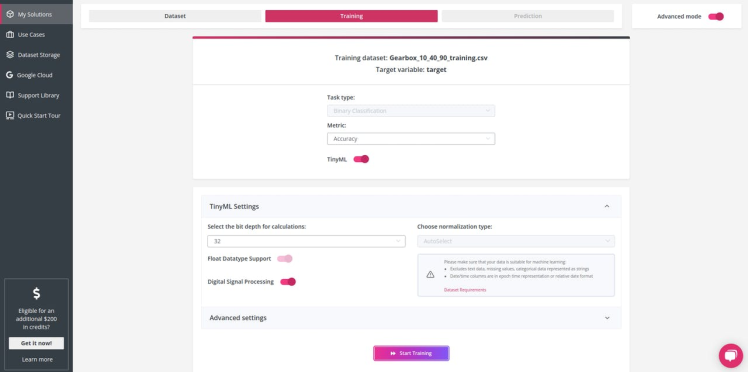

Since the dataset is a vibration, we need to prepare the data before training the model. To do this, I select the setting Digital Signal Processing (DSP).

Digital Signal Processing (DSP) option enables automatic preprocessing and feature extraction for data from gyroscopes, accelerometers, magnetometers, electromyography (EMG), etc. Neuton will automatically transform raw data and extract additional features to create precise models for signal classification.

For this model, we use Accuracy as a metric (but you can experiment with all available metrics).

While the model is being trained, you can check out Exploratory Data Analysis generated once the data processing is complete, check the below video:

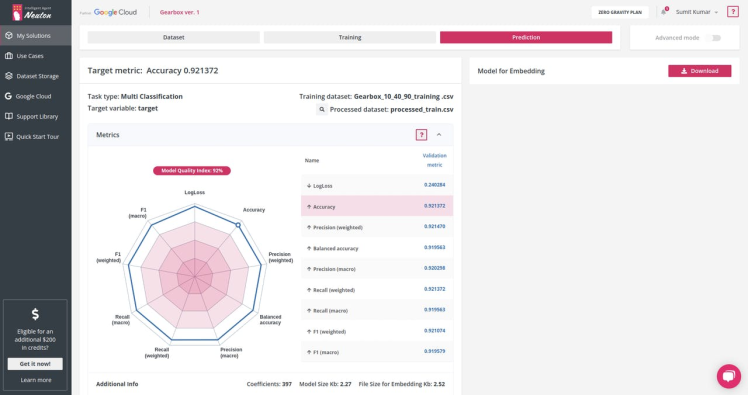

The target metric for me was: Accuracy 0.921372 and the trained model had the following characteristics:

Number of coefficients = 397, File Size for Embedding = 2.52 Kb. That's super cool! It is a really small model! Upon the model training completion, click on the Prediction tab, and then click on the Download button next to Model for Embedding to download the model library file that we are going to use for our device.

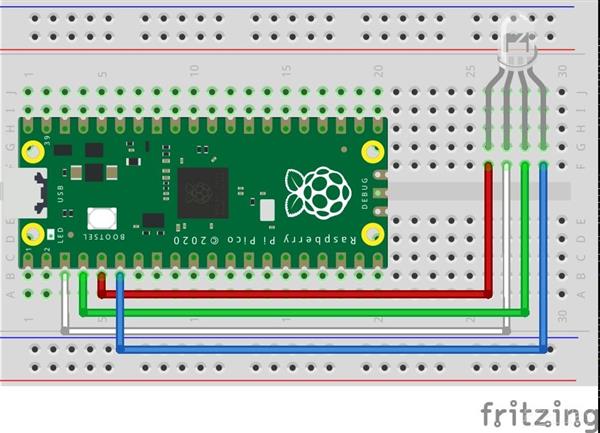

Step 2: Embedding on Raspberry Pico

Once you have downloaded the model files, it's time to add our custom functions and actions. I am using Arduino IDE to program Raspberry Pico.

Setting up Arduino IDE for Raspberry Pico:

This is how it works on MCU. The lights indicate if the Gearbox is broken or not. Let′s see how to achieve this result step by step.

I used Ubuntu for this tutorial, but the same instructions should work for other Debian-based distributions such as Raspberry Pi OS.

1. Open a terminal and use wget to download the official Pico setup script.

$ wget https://raw.githubusercontent.com/raspberrypi/pico-setup/master/pico_setup.sh

2. In the same terminal modify the downloaded file so that it is executable.

$ chmod +x pico_setup.sh

3. Run pico_setup.sh to start the installation process. Enter your sudo password if prompted.

$ ./pico_setup.sh

4. Download the Arduino IDE and install it on your machine.

5. Open a terminal and add your user to the group “dialout” and Log out or reboot your computer for the changes to take effect.

$ sudo usermod -a -G dialout “$USER”

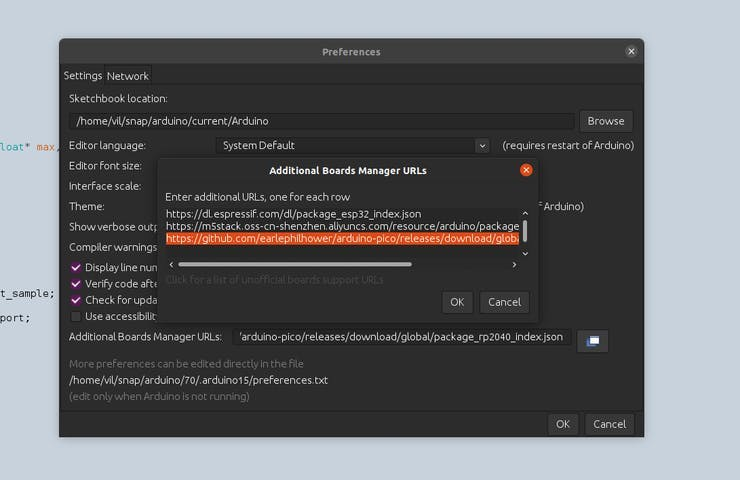

6. Open the Arduino application and go to File >> Preferences. In the additional boards' manager add this line and click OK.

https://github.com/earlephilhower/arduino-pico/releases/download/global/package_rp2040_index.json

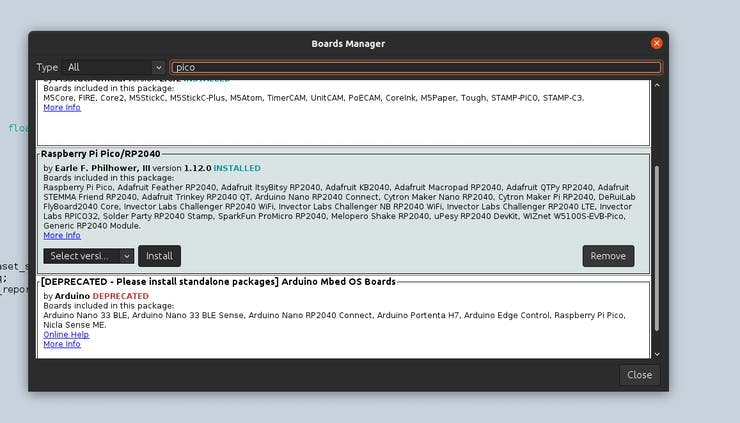

7. Go to Tools >> Board >> Boards Manager. Type “pico” in the search box and then install the Raspberry Pi Pico / RP2040 board. This will trigger another large download, approximately 300MB in size.

Note: Since we are going to make classification on the test dataset, we will use the CSV utility provided by Neuton to run inference on the data sent to the MCU via USB.

Here is our project directory,

user@desktop:~/Documents/Gearbox$ tree

.

├── application.c

├── application.h

├── checksum.c

├── checksum.h

├── Gearbox.ino

├── model

│ └── model.h

├── neuton.c

├── neuton.h

├── parser.c

├── parser.h

├── protocol.h

├── StatFunctions.c

├── StatFunctions.h

3 directories, 14 files

1 directory, 13 files

Checksum, parser program files are for generating handshake with the CSV serial utility tool and sending column data to the Raspberry Pico for inference.

Understanding the code part in Gearbox.ino file, we set different callbacks for monitoring CPU, time, and memory usage used while inferencing.

void setup() {

Serial.begin(230400);

while (!Serial);

pinMode(LED_RED, OUTPUT);

pinMode(LED_BLUE, OUTPUT);

pinMode(LED_GREEN, OUTPUT);

digitalWrite(LED_RED, LOW);

digitalWrite(LED_BLUE, LOW);

digitalWrite(LED_GREEN, LOW);

callbacks.send_data = send_data;

callbacks.on_dataset_sample = on_dataset_sample;

callbacks.get_cpu_freq = get_cpu_freq;

callbacks.get_time_report = get_time_report;

init_failed = app_init(&callbacks);

}

The real magic happens here callbacks.on_dataset_sample=on_dataset_sample

static float* on_dataset_sample(float* inputs)

{

if (neuton_model_set_inputs(inputs) == 0)

{

uint16_t index;

float* outputs;

uint64_t start = micros();

if (neuton_model_run_inference(&index, &outputs) == 0)

{

uint64_t stop = micros();

uint64_t inference_time = stop - start;

if (inference_time > max_time)

max_time = inference_time;

if (inference_time < min_time)

min_time = inference_time;

static uint64_t nInferences = 0;

if (nInferences++ == 0)

{

avg_time = inference_time;

}

else

{

avg_time = (avg_time * nInferences + inference_time) / (nInferences + 1);

}

digitalWrite(LED_RED, LOW);

digitalWrite(LED_BLUE, LOW);

digitalWrite(LED_GREEN, LOW);

switch (index)

{

/**

Green Light means Gearbox Broken (10% load), Blue Light means Gearbox Broken (40% load), and Red Light means Gearbox Broken (90% load) based upon the CSV test dataset received via Serial.

**/

case 0:

//Serial.println("0: Healthy 10% load");

break;

case 1:

//Serial.println("1: Broken 10% load");

digitalWrite(LED_GREEN, HIGH);

break;

case 2:

//Serial.println("2: Healthy 40% load");

break;

case 3:

//Serial.println("3: Broken 40% load");

digitalWrite(LED_BLUE, HIGH);

break;

case 4:

//Serial.println("4: Healthy 90% load");

break;

case 5:

//Serial.println("5: Broken 90% load");

digitalWrite(LED_RED, HIGH);

break;

default:

break;

}

return outputs;

}

}

return NULL;

}

Once the input variables are ready, neuton_model_run_inference(&index, &outputs) is called which runs inference and returns outputs.

Installing CSV dataset Uploading Utility (Currently works on Linux and macOS only)

Install dependencies,

# For Ubuntu

$ sudo apt install libuv1-dev gengetopt

# For macOS

$ brew install libuv gengetopt

Clone this repo,

$ git clone https://github.com/Neuton-tinyML/dataset-uploader.git

$ cd dataset-uploader

Run make to build the binaries,

$ make

Once it's done, you can try running the help command, it's should be similar to that shown below

user@desktop:~/dataset-uploader$ ./uploader -h

Usage: uploader [OPTION]...

Tool for upload CSV file MCU

-h, --help Print help and exit

-V, --version Print version and exit

-i, --interface=STRING interface (possible values="udp", "serial"

default=`serial')

-d, --dataset=STRING Dataset file (default=`./dataset.csv')

-l, --listen-port=INT Listen port (default=`50000')

-p, --send-port=INT Send port (default=`50005')

-s, --serial-port=STRING Serial port device (default=`/dev/ttyACM0')

-b, --baud-rate=INT Baud rate (possible values="9600", "115200",

"230400" default=`230400')

--pause=INT Pause before start (default=`0')

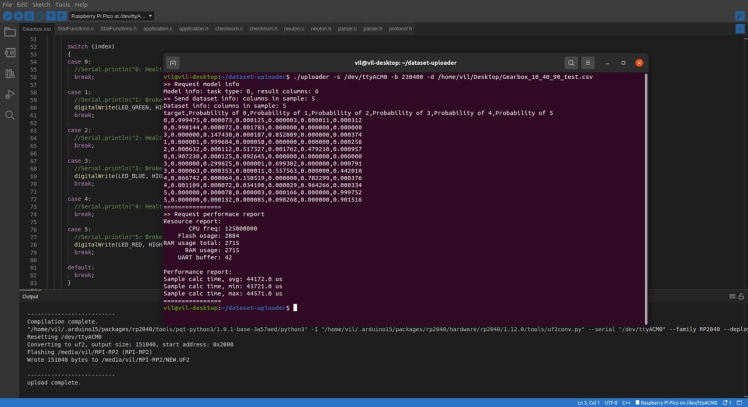

Step 3: Running inference on Raspberry Pico

Upload the program on the Raspberry Pico,

Once uploaded and running, open a new terminal and run this command:

$ ./uploader -s /dev/ttyACM0 -b 230400 -d /home/vil/Desktop/Gearbox_10_40_90_test.csv

The inference has started running, once it is completed for the whole CSV dataset it will print a full summary.

>> Request performace report

Resource report:

CPU freq: 125000000

Flash usage: 2884

RAM usage total: 2715

RAM usage: 2715

UART buffer: 42

Performance report:

Sample calc time, avg: 44172.0 us

Sample calc time, min: 43721.0 us

Sample calc time, max: 44571.0 us

I tried to build the same model with TensorFlow and TensorFlow Lite as well. My model built with Neuton TinyML turned out to be 4.3% better in terms of Accuracy and 15.3 times smaller in terms of model size than the one built with TF Lite. Speaking of the number of coefficients, TensorFlow's model has, 9, 330 coefficients, while Neuton's model has only 397 coefficients (which is 23.5 times smaller than TF!).

The resultant model footprint and inference time are as follows:

Conclusion

This tutorial vividly demonstrates the huge impact that TinyML technologies can provide on the automotive industry. You can have literally zero data science knowledge but still, rapidly build super compact ML models to effectively solve practical challenges. And the best part, it's all possible by using an absolutely free solution and a super cheap MCU!

TinyML Gearbox Fault Prediction on a $4 MCU

Raspberry Pi 5 7 Inch Touch Screen IPS 1024x600 HD LCD HDMI-compatible Display for RPI 4B 3B+ OPI 5 AIDA64 PC Secondary Screen(Without Speaker)

BUY NOW

ESP32-S3 4.3inch Capacitive Touch Display Development Board, 800×480, 5-point Touch, 32-bit LX7 Dual-core Processor

BUY NOW

Raspberry Pi 5 7 Inch Touch Screen IPS 1024x600 HD LCD HDMI-compatible Display for RPI 4B 3B+ OPI 5 AIDA64 PC Secondary Screen(Without Speaker)

BUY NOW- Comments(0)

- Likes(0)

Log in to post comments.

Log in to post comments.

- 0 USER VOTES

- YOUR VOTE 0.00 0.00

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

More by vilaksh01

More by vilaksh01

-

CliSensio - Climate Sensing and Insect Infestation Control

Overview:Climate Change, is a highly debated high school topic, but do we really care about it? We s...

CliSensio - Climate Sensing and Insect Infestation Control

Overview:Climate Change, is a highly debated high school topic, but do we really care about it? We s...

-

AI For truck APS Failure Detection on a $4 MCU

IntroductionThe automotive industry is among the pioneers to adopt cutting-edge technologies, machin...

AI For truck APS Failure Detection on a $4 MCU

IntroductionThe automotive industry is among the pioneers to adopt cutting-edge technologies, machin...

-

New Era Farming with TensorFlow on Lowest Power Consumption

Overview:This project demonstrates how to build a device using TensorFlow and Artemis module to solv...

New Era Farming with TensorFlow on Lowest Power Consumption

Overview:This project demonstrates how to build a device using TensorFlow and Artemis module to solv...

-

TinyML Gearbox Fault Prediction on a $4 MCU

StoryIs it possible to make an AI-driven system that predicts gearbox failure on a simple $4 MCU? Ho...

TinyML Gearbox Fault Prediction on a $4 MCU

StoryIs it possible to make an AI-driven system that predicts gearbox failure on a simple $4 MCU? Ho...

-

AREC - Agricultural Records On Electronic Contracts

Objective:One of the biggest reasons behind the growth of fake products in the agrochemical industry...

AREC - Agricultural Records On Electronic Contracts

Objective:One of the biggest reasons behind the growth of fake products in the agrochemical industry...

-

AquaMon - Aquaponics and Fish Tank Monitoring with Tuya IoT

IntroductionDo you love sea creatures? I don't think I would find a single person who would not fall...

AquaMon - Aquaponics and Fish Tank Monitoring with Tuya IoT

IntroductionDo you love sea creatures? I don't think I would find a single person who would not fall...

-

Predictive Maintenance Of Compressor Water Pumps

An ordinary resident of a metropolis rarely thinks about how water enters taps or central heating pi...

Predictive Maintenance Of Compressor Water Pumps

An ordinary resident of a metropolis rarely thinks about how water enters taps or central heating pi...

-

Unlock Passwords With Tinyml-based Digit Recognition

Story? IntroductionThe active development of smart gadgets with touch interfaces is trending nowaday...

Unlock Passwords With Tinyml-based Digit Recognition

Story? IntroductionThe active development of smart gadgets with touch interfaces is trending nowaday...

-

Handmade Drawing Recognition Interface As From My Smartphone

StoryIntroductionI was inspired by such features on our smartphones. My smartphone “Vivo V7” has a f...

Handmade Drawing Recognition Interface As From My Smartphone

StoryIntroductionI was inspired by such features on our smartphones. My smartphone “Vivo V7” has a f...

-

Recognizing MNIST-based Handwritten Digits on M5Stack Core2

IntroductionIn my previous experiment, I had great fun adding handmade drawing gestures for our M5St...

Recognizing MNIST-based Handwritten Digits on M5Stack Core2

IntroductionIn my previous experiment, I had great fun adding handmade drawing gestures for our M5St...

-

Tuya Link SDK IoT Smart Environment Sensing And Humidifier

IntroductionI had been exploring the Tuya IoT platform for the past few months and they never fail t...

Tuya Link SDK IoT Smart Environment Sensing And Humidifier

IntroductionI had been exploring the Tuya IoT platform for the past few months and they never fail t...

-

Tuya IoT Cloud Smart Weather Lamp

IntroductionHello everybody, ever felt like having a smart home device to visually show/signal you t...

Tuya IoT Cloud Smart Weather Lamp

IntroductionHello everybody, ever felt like having a smart home device to visually show/signal you t...

-

Getting Started With Arduino IoT Control With Tuya

Introduction:I have always enjoyed using Arduino UNO since it was my first programmable board but it...

Getting Started With Arduino IoT Control With Tuya

Introduction:I have always enjoyed using Arduino UNO since it was my first programmable board but it...

-

Coronavirus - India cases tracker

Today everyone is gazing at their phone to keep track of the coronavirus in their country but we ten...

Coronavirus - India cases tracker

Today everyone is gazing at their phone to keep track of the coronavirus in their country but we ten...

-

CliSensio - Climate Sensing and Insect Infestation Control

Overview:Climate Change, is a highly debated high school topic, but do we really care about it? We s...

CliSensio - Climate Sensing and Insect Infestation Control

Overview:Climate Change, is a highly debated high school topic, but do we really care about it? We s...

-

AI For truck APS Failure Detection on a $4 MCU

IntroductionThe automotive industry is among the pioneers to adopt cutting-edge technologies, machin...

AI For truck APS Failure Detection on a $4 MCU

IntroductionThe automotive industry is among the pioneers to adopt cutting-edge technologies, machin...

-

New Era Farming with TensorFlow on Lowest Power Consumption

Overview:This project demonstrates how to build a device using TensorFlow and Artemis module to solv...

New Era Farming with TensorFlow on Lowest Power Consumption

Overview:This project demonstrates how to build a device using TensorFlow and Artemis module to solv...

-

TinyML Gearbox Fault Prediction on a $4 MCU

StoryIs it possible to make an AI-driven system that predicts gearbox failure on a simple $4 MCU? Ho...

TinyML Gearbox Fault Prediction on a $4 MCU

StoryIs it possible to make an AI-driven system that predicts gearbox failure on a simple $4 MCU? Ho...

-

AREC - Agricultural Records On Electronic Contracts

Objective:One of the biggest reasons behind the growth of fake products in the agrochemical industry...

AREC - Agricultural Records On Electronic Contracts

Objective:One of the biggest reasons behind the growth of fake products in the agrochemical industry...

-

AquaMon - Aquaponics and Fish Tank Monitoring with Tuya IoT

IntroductionDo you love sea creatures? I don't think I would find a single person who would not fall...

AquaMon - Aquaponics and Fish Tank Monitoring with Tuya IoT

IntroductionDo you love sea creatures? I don't think I would find a single person who would not fall...

-

Predictive Maintenance Of Compressor Water Pumps

An ordinary resident of a metropolis rarely thinks about how water enters taps or central heating pi...

Predictive Maintenance Of Compressor Water Pumps

An ordinary resident of a metropolis rarely thinks about how water enters taps or central heating pi...

-

Unlock Passwords With Tinyml-based Digit Recognition

Story? IntroductionThe active development of smart gadgets with touch interfaces is trending nowaday...

Unlock Passwords With Tinyml-based Digit Recognition

Story? IntroductionThe active development of smart gadgets with touch interfaces is trending nowaday...

-

Handmade Drawing Recognition Interface As From My Smartphone

StoryIntroductionI was inspired by such features on our smartphones. My smartphone “Vivo V7” has a f...

Handmade Drawing Recognition Interface As From My Smartphone

StoryIntroductionI was inspired by such features on our smartphones. My smartphone “Vivo V7” has a f...

-

Recognizing MNIST-based Handwritten Digits on M5Stack Core2

IntroductionIn my previous experiment, I had great fun adding handmade drawing gestures for our M5St...

Recognizing MNIST-based Handwritten Digits on M5Stack Core2

IntroductionIn my previous experiment, I had great fun adding handmade drawing gestures for our M5St...

-

Tuya Link SDK IoT Smart Environment Sensing And Humidifier

IntroductionI had been exploring the Tuya IoT platform for the past few months and they never fail t...

Tuya Link SDK IoT Smart Environment Sensing And Humidifier

IntroductionI had been exploring the Tuya IoT platform for the past few months and they never fail t...

-

Tuya IoT Cloud Smart Weather Lamp

IntroductionHello everybody, ever felt like having a smart home device to visually show/signal you t...

Tuya IoT Cloud Smart Weather Lamp

IntroductionHello everybody, ever felt like having a smart home device to visually show/signal you t...

-

-

Commodore 64 1541-II 1581 Floppy Disk Drive C64 Power Supply Unit USB-C 5V 12V DIN connector 5.25

188 1 3 -

Easy to print simple stacking organizer with drawers

93 0 0 -

-

-

-

-

-

-

Modifying a Hotplate to a Reflow Solder Station

1163 1 6 -

MPL3115A2 Barometric Pressure, Altitude, and Temperature Sensor

653 0 1 -