Variable Breadboard Power Supply

Variable Breadboard Power Module

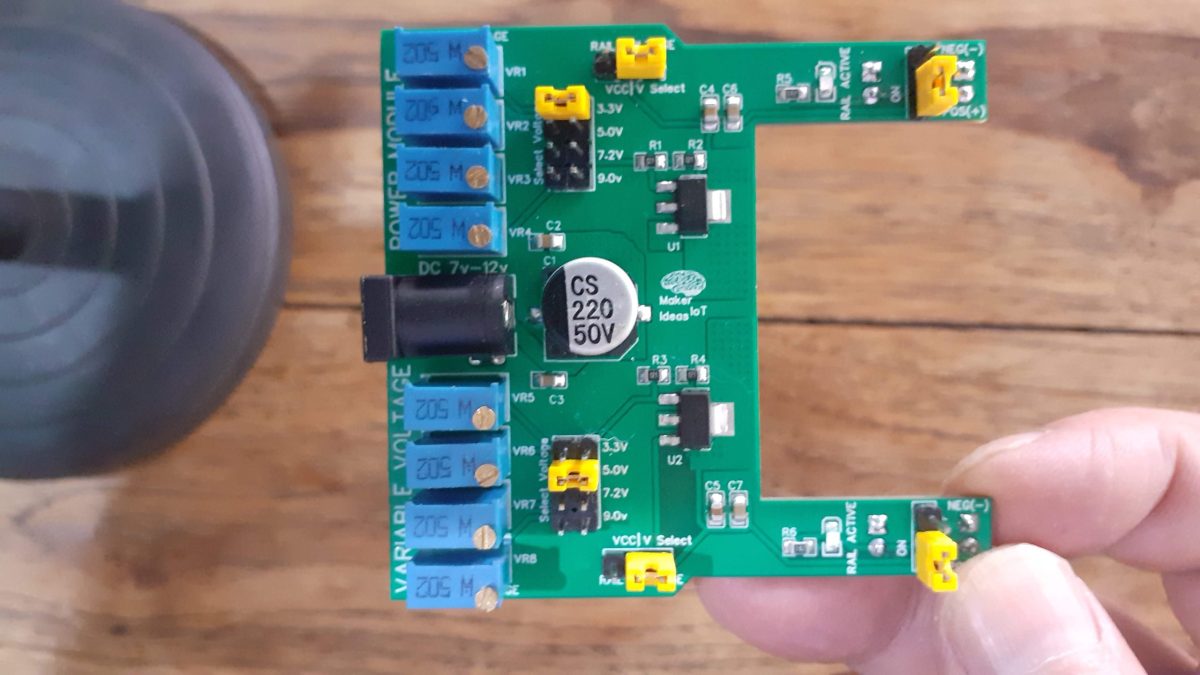

A few weeks ago, I designed and built my own breadboard power module, mainly to try and solve some perceived problems with commercial ones, and also just to have something that is completely my own.

While that design does indeed work very well, I did however find a few tiny issues that still needed attention.

Two fixed voltages, 3.3v and 5.0v

1A current limit per regulator

PCB Heatsink design can be improved further, as there is still a bit too much heat at a high current draw – not much actually, but I like things running as cool as possible.

Other requirements that popped up were the ability to have more than two set voltages, as well as being able to send the full Vsupply to a power rail if I choose to do so…

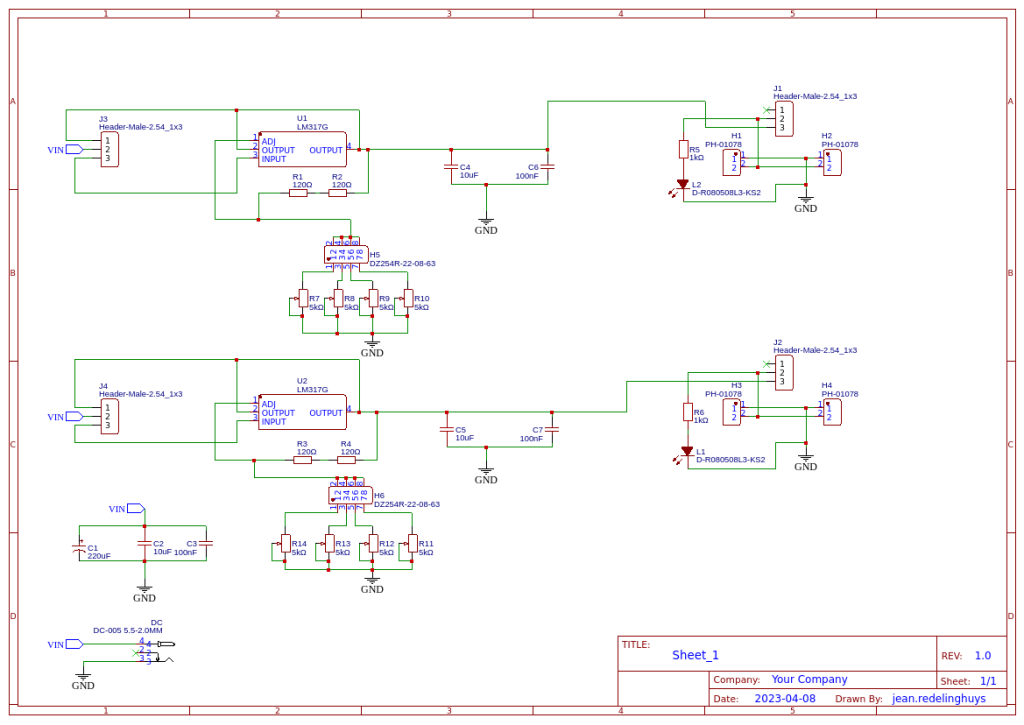

Having a few LM317G variable voltage regulators lying around, left over from a previous project, I decided to use those. They can source an additional 500mA of current (1500mA in total) and also makes it quite easy to have variable voltages.

Voltage is set with two resistors, of which one is usually a variable resistor. This does however mean that you need a multimeter or other device capable of measuring voltage each time that you need a different voltage, as well as to determine at what voltage the device is currently set if you have not used it in a while…

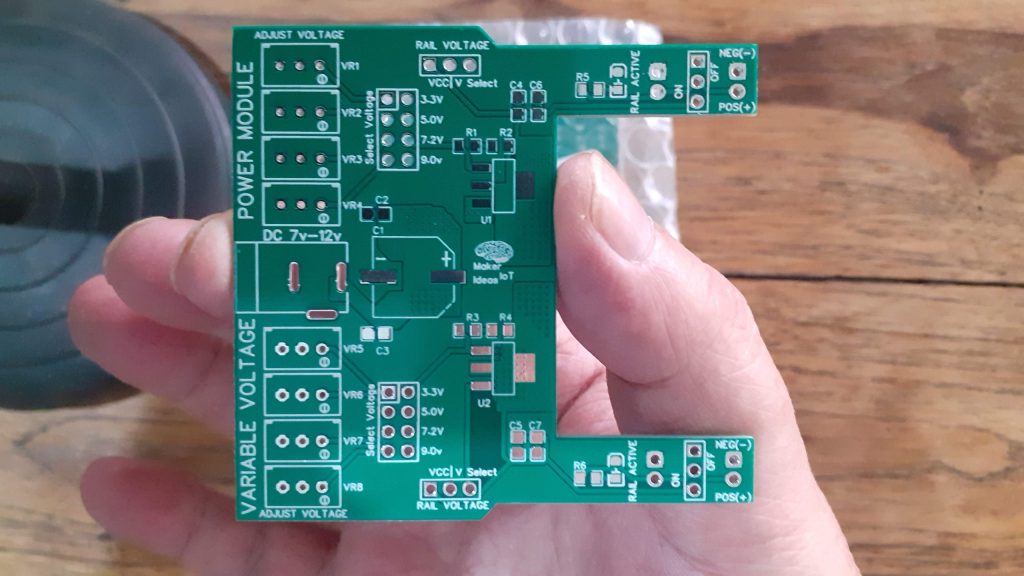

The initial prototype is quite bulky at the moment, but I do plan to change that in the future when I am completely happy with the performance of the module

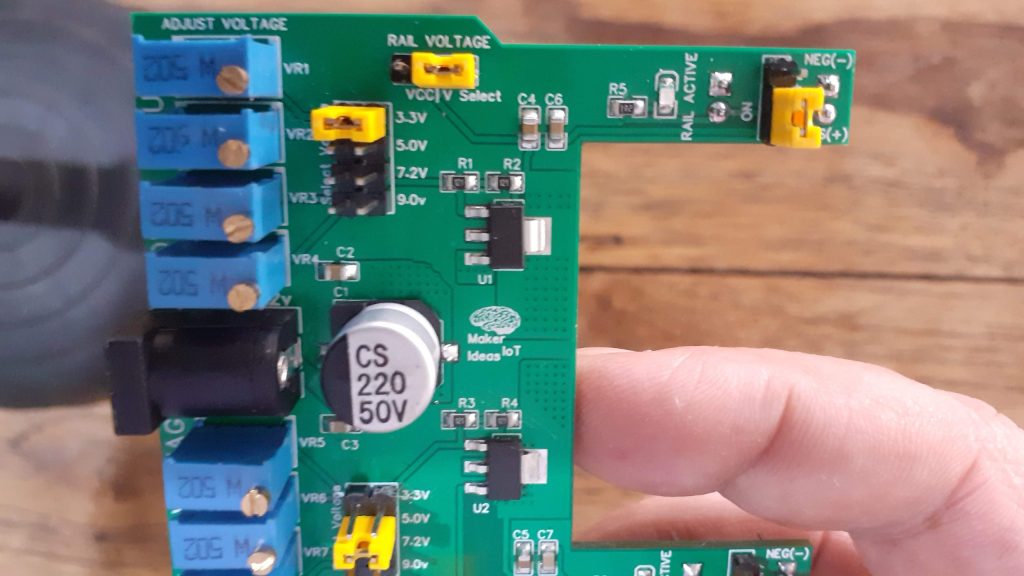

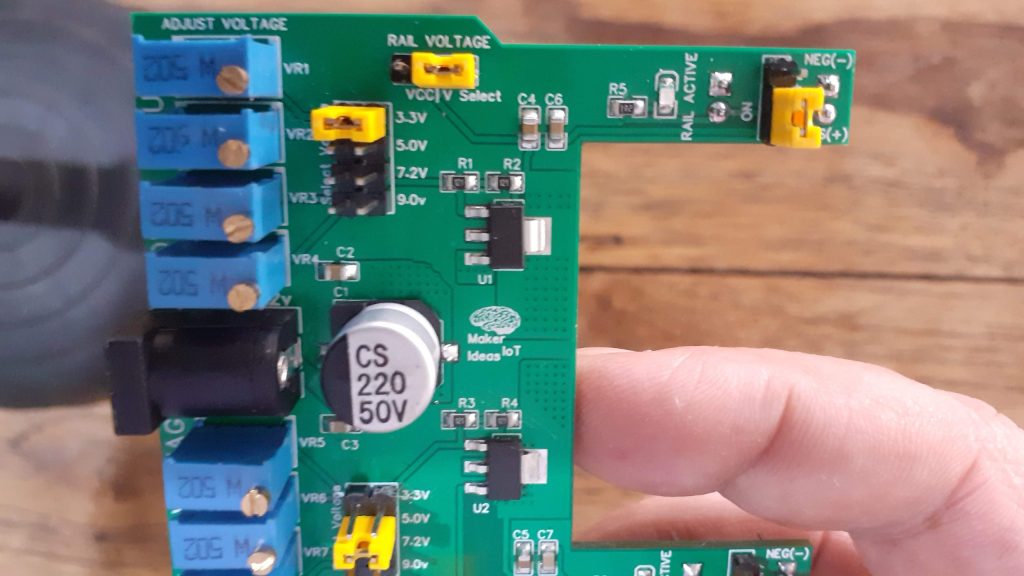

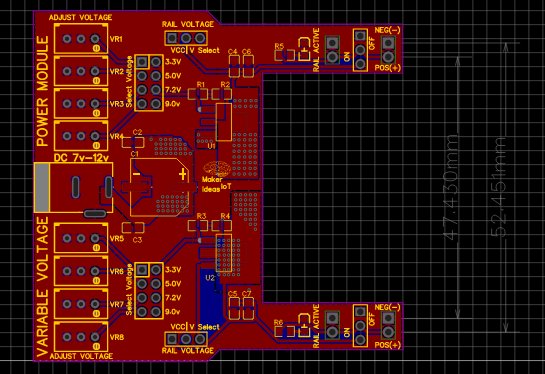

Each “voltage channel” consists of a 5k multiturn “trim pot” that connects back through a selectable jumper to a 240-ohm resistor ( I actually used two precision 120-ohm resistors in series) on the adjust pin of the regulator.

I have also reduced the number of smoothing capacitors on the input and outputs, as the voltages are quite stable

After assembly, it only takes a few minutes to adjust each “trim pot” to the correct value using a small screwdriver and a multimeter. Once set and verified, they can be locked using a drop of “lock-tight” or similar.

The eight “trim pots” sets the voltages as follows:

Top Rail:

VR1 – 3.3v

VR2 – 5.0v

VR3 – 7.2v

VR4 – 9.0v

Bottom Rail:

VR5 – 3.3v

VR6 – 5.0v

VR7 – 7.2v

VR8 – 9.0v

Turning the “pot” anti-clockwise reduces the voltage, while a clockwise movement increases it.

Changing voltages then becomes as easy as changing a jumper to a preset position.

The Schematic

As mentioned above, I have used two precision 120-ohm resistors on one leg of the resister divider that is connected to the adjust leg. Feel free to replace that with a single 240-ohm resistor and a 0-ohm bridge.

The multiturn precision 5k trim pots give great control and the desired voltages can be dialled in very accurately.

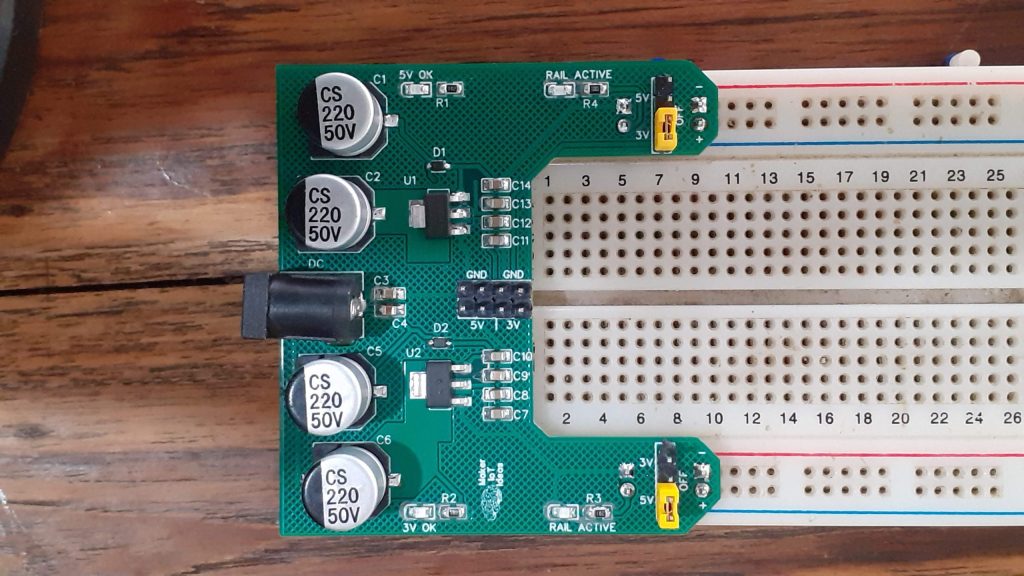

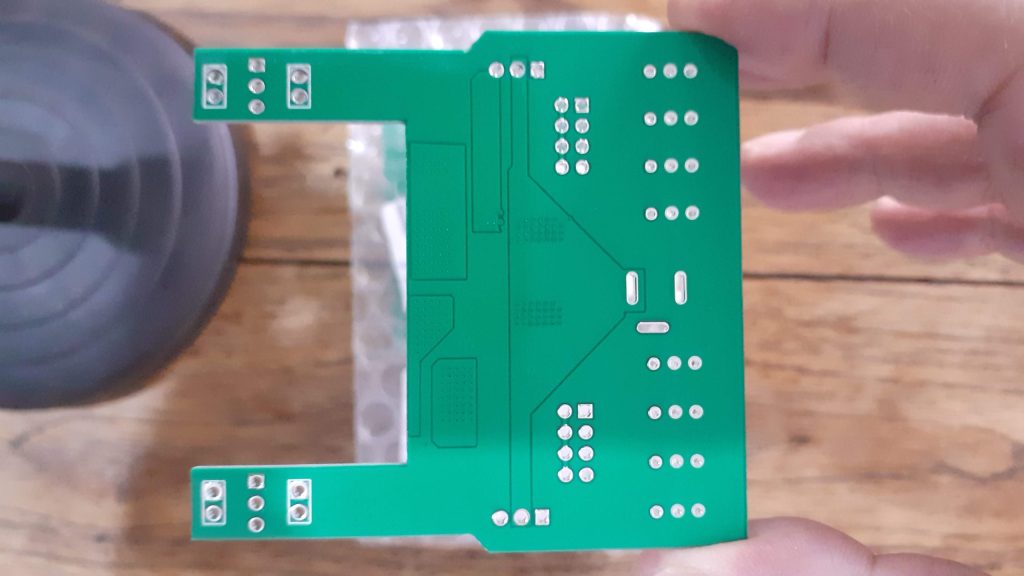

The module was designed as a double-layer PCB. I used big solid ground planes to provide good grounding, as well as serve as heat sinks for the voltage regulators.

Assembly

The assembly of this module is quite easy, no stencil is required. I recommend that you take care of the SMD components first, using hot -air or even hand soldering them, before assembling the through-hole components.

Here I do recommend that you use a breadboard to make sure that the 2.54mm headers that will connect to the power rails are lined up nicely

Testing and Setup

As already described above, the module does require a bit of setup after assembly. To do this, you will require a DC power supply with a voltage of 7v to 12v, as well as a multimeter, preferably with clips on the test leads, as well as a small terminal screwdriver.

With the module powered, and the Rail Voltage jumpers set to VCC, measure the rail outputs with the multimeter ( remember that the rail active jumper MUST be set to on). Both rails should be at the same voltage as your VCC input voltage, ie 12v DC

Move the Select Voltage jumper for both rails to the 3.3v position, and the Rail voltage jumper to the VSelect position for both rails.

With the multimeter connected to each rail in turn, turn VR1 anti-clockwise until the voltage for the top rail is set to 3.3v. Repeat for the bottom rail, adjusting VR5 instead, while measuring the bottom rail.

Repeat this step for each of the voltages, remember to power off the module before changing jumper positions – to prevent accidental short circuits…

Variable Breadboard Power Supply

*PCBWay community is a sharing platform. We are not responsible for any design issues and parameter issues (board thickness, surface finish, etc.) you choose.

- Comments(0)

- Likes(1)

-

Snoop67

Apr 29,2023

Snoop67

Apr 29,2023

- 0 USER VOTES

- YOUR VOTE 0.00 0.00

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

More by Jean Redelinghuys MakerIoT2020

More by Jean Redelinghuys MakerIoT2020

-

PCB_MCP23008_2023-10-08

MCP23008 BreakoutI designed this breakout to assist me during prototyping my next version of the “RP...

PCB_MCP23008_2023-10-08

MCP23008 BreakoutI designed this breakout to assist me during prototyping my next version of the “RP...

-

PCB_XiaoRP2040-Mouse-REV2

Xiao RP2040 Joystick Mouse – revision 2.00Revision 1.0 of the ProjectOver the last few months, I hav...

PCB_XiaoRP2040-Mouse-REV2

Xiao RP2040 Joystick Mouse – revision 2.00Revision 1.0 of the ProjectOver the last few months, I hav...

-

Multi Purpose IO Card

Multi-Purpose IO CardWhen we are working on a prototype, we always need access to pushbuttons, encod...

Multi Purpose IO Card

Multi-Purpose IO CardWhen we are working on a prototype, we always need access to pushbuttons, encod...

-

Variable Voltage Power Module

Variable Voltage Power ModulePowering electronics projects are always challenging. This Variable vol...

Variable Voltage Power Module

Variable Voltage Power ModulePowering electronics projects are always challenging. This Variable vol...

-

I2C Matrix Keypad

An I2C Matrix KeypadThe completed I2C Matrix KeypadIn a previous post this month I introduced my 4×4...

I2C Matrix Keypad

An I2C Matrix KeypadThe completed I2C Matrix KeypadIn a previous post this month I introduced my 4×4...

-

ESP32-S Development Board, in "Arduino Uno" form factor

UPDATE 24/06/2023:This board now has a Hardware Revision 2.0 available. It is the same board but wit...

ESP32-S Development Board, in "Arduino Uno" form factor

UPDATE 24/06/2023:This board now has a Hardware Revision 2.0 available. It is the same board but wit...

-

W307186ASC94_Gerber_PCB_USB-Ports

USB Power Supply ModuleUSB Ports are quite handy to power all our day-to-day electronic devices, but...

W307186ASC94_Gerber_PCB_USB-Ports

USB Power Supply ModuleUSB Ports are quite handy to power all our day-to-day electronic devices, but...

-

Atmega 328P based PWM controller Card

ATMega 328P Based PWM controller CardAs part of my recent ESP-12E I2C Base Board project, I designed...

Atmega 328P based PWM controller Card

ATMega 328P Based PWM controller CardAs part of my recent ESP-12E I2C Base Board project, I designed...

-

W307186ASC71_Gerber_PCB_ESP-Now Remote

Today we will look at the remote control unit for the Robotic Toy Car – Part 6.The project is close ...

W307186ASC71_Gerber_PCB_ESP-Now Remote

Today we will look at the remote control unit for the Robotic Toy Car – Part 6.The project is close ...

-

W307186ASV69_Gerber_PCB_Robot-Car-MCU-Board Prototype

In our last project, we started working on repurposing an old toy car. In this part, Robot Toy Car –...

W307186ASV69_Gerber_PCB_Robot-Car-MCU-Board Prototype

In our last project, we started working on repurposing an old toy car. In this part, Robot Toy Car –...

-

W307186ASV62_Gerber_PCB_DUAL-H-Bridge

by makeriot2020 on May 27, 2022Many of us have old toys laying around the house, they belong to ou...

W307186ASV62_Gerber_PCB_DUAL-H-Bridge

by makeriot2020 on May 27, 2022Many of us have old toys laying around the house, they belong to ou...

-

CAN-BUS Breakout

Breadboard Compatible CAN-BUS Breakout ModuleWhat is this:Some of us have already used the commonly ...

CAN-BUS Breakout

Breadboard Compatible CAN-BUS Breakout ModuleWhat is this:Some of us have already used the commonly ...

-

RA-02 Breakout with Level converters

Breadboard and beginner-friendly RA-02 Breakout ModuleMost Makers and electronics enthusiasts may al...

RA-02 Breakout with Level converters

Breadboard and beginner-friendly RA-02 Breakout ModuleMost Makers and electronics enthusiasts may al...

-

ATMEGA328P Module with integrated LoRa and CAN Bus

ATMEGA328P Module with integrated LoRa and CAN-BUSINTRODUCTIONIn my quest to perfect my LoRa telemet...

ATMEGA328P Module with integrated LoRa and CAN Bus

ATMEGA328P Module with integrated LoRa and CAN-BUSINTRODUCTIONIn my quest to perfect my LoRa telemet...

-

Sx127x-Ra-02-Test-Module with ATMEGA328P-AU

SX127x LoRa/FSK/OOK Prototype Radio BoardI recently had a requirement to do some automation/telemetr...

Sx127x-Ra-02-Test-Module with ATMEGA328P-AU

SX127x LoRa/FSK/OOK Prototype Radio BoardI recently had a requirement to do some automation/telemetr...

-

USB-ASP Programmer ATMEGA8

Build your own USB-ASP Programmer CloneBymakeriot2020 FEB 21, 2022 Arduino, ASP programmerUsing mor...

USB-ASP Programmer ATMEGA8

Build your own USB-ASP Programmer CloneBymakeriot2020 FEB 21, 2022 Arduino, ASP programmerUsing mor...

-

ATTiny1616-LIGHT-Controller-with-CAN_B_PCB_ATTiny1616-LIGHT-Controller-with-C_2024-09-11

Assembly of the ATTiny1616 Can bus controller PCBThe Assembly of the ATTiny1616 Can Bus Controller P...

ATTiny1616-LIGHT-Controller-with-CAN_B_PCB_ATTiny1616-LIGHT-Controller-with-C_2024-09-11

Assembly of the ATTiny1616 Can bus controller PCBThe Assembly of the ATTiny1616 Can Bus Controller P...

-

ATTiny1616QFN-CAN-Remote-Neopixel-Ligh_PCB_ATTiny1616QFN-CAN-Remote-Neopixel-2024-09-11_2024-09-11

NeoPixel CAN-Bus Module with local controlAs part of my current project to add NeoPixels to the cabi...

ATTiny1616QFN-CAN-Remote-Neopixel-Ligh_PCB_ATTiny1616QFN-CAN-Remote-Neopixel-2024-09-11_2024-09-11

NeoPixel CAN-Bus Module with local controlAs part of my current project to add NeoPixels to the cabi...

-

-

mammoth-3D SLM Voron Toolhead – Manual Drill & Tap Edition

88 0 0 -

-

AEL-2011 Power Supply Module

602 0 2 -

AEL-2011 50W Power Amplifier

542 0 2 -

-

-

Custom Mechanical Keyboard

746 0 0 -

Tester for Touch Screen Digitizer without using microcontroller

371 2 2 -

Audio reactive glow LED wristband/bracelet with NFC / RFID-Tags

346 0 1 -

-