ATTiny1616-LIGHT-Controller-with-CAN_B_PCB_ATTiny1616-LIGHT-Controller-with-C_2024-09-11

Assembly of the ATTiny1616 Can bus controller PCB

The Assembly of the ATTiny1616 Can Bus Controller PCB will be covered in this post. This PCB took quite a bit of time, due to having a real-world job that takes up an extreme amount of my time.

Enough of that, let’s get started

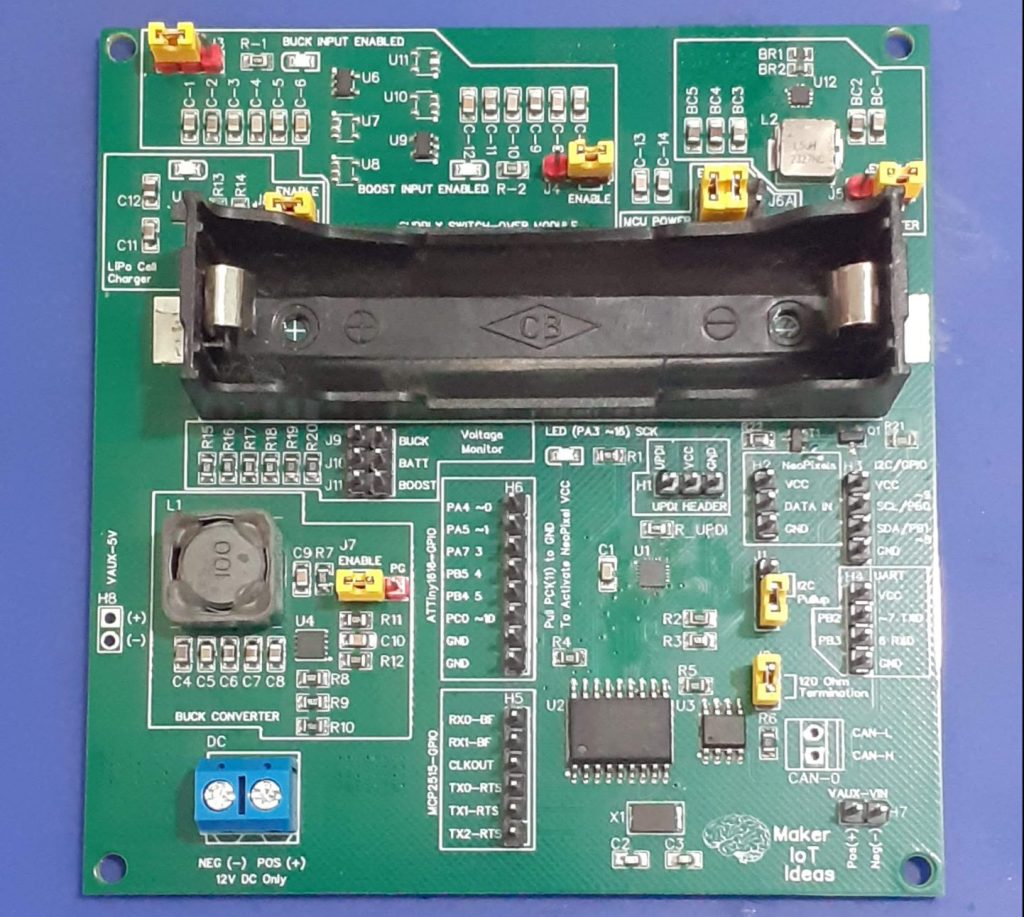

The PCB

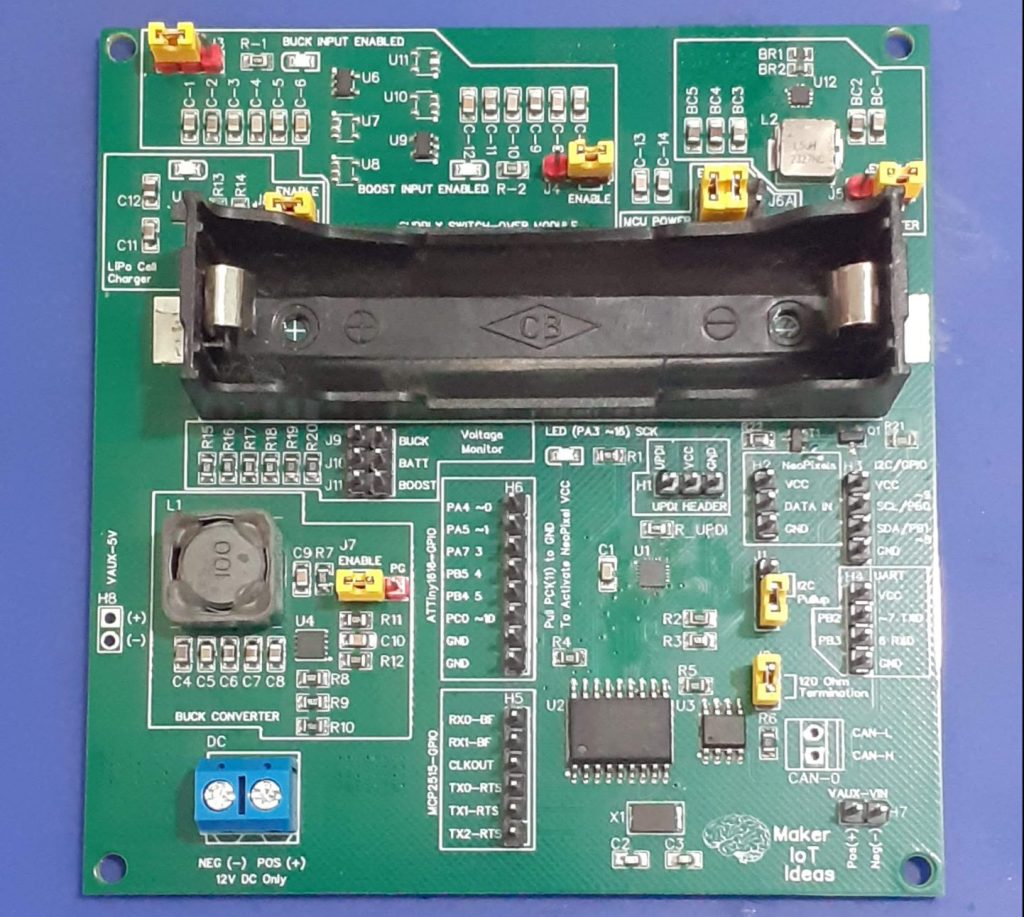

The PCB is a double layer, with mostly SMD components, and as mentioned in the initial post, broken up into functional blocks to make testing easier. I will also take the time to mention some performance and problem issues that I have encountered during the testing phase here are well

These include:

– a buck converter power supply module to provide 5v DC.

– a single-cell lipo cell charger circuit

– an ideal diode supply or-ing circuit

– a boost converter

– various jumpers, so enable/disable certain parts of the circuit

– microcontroller and logic circuits

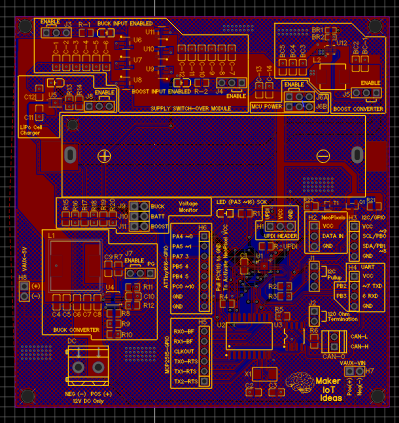

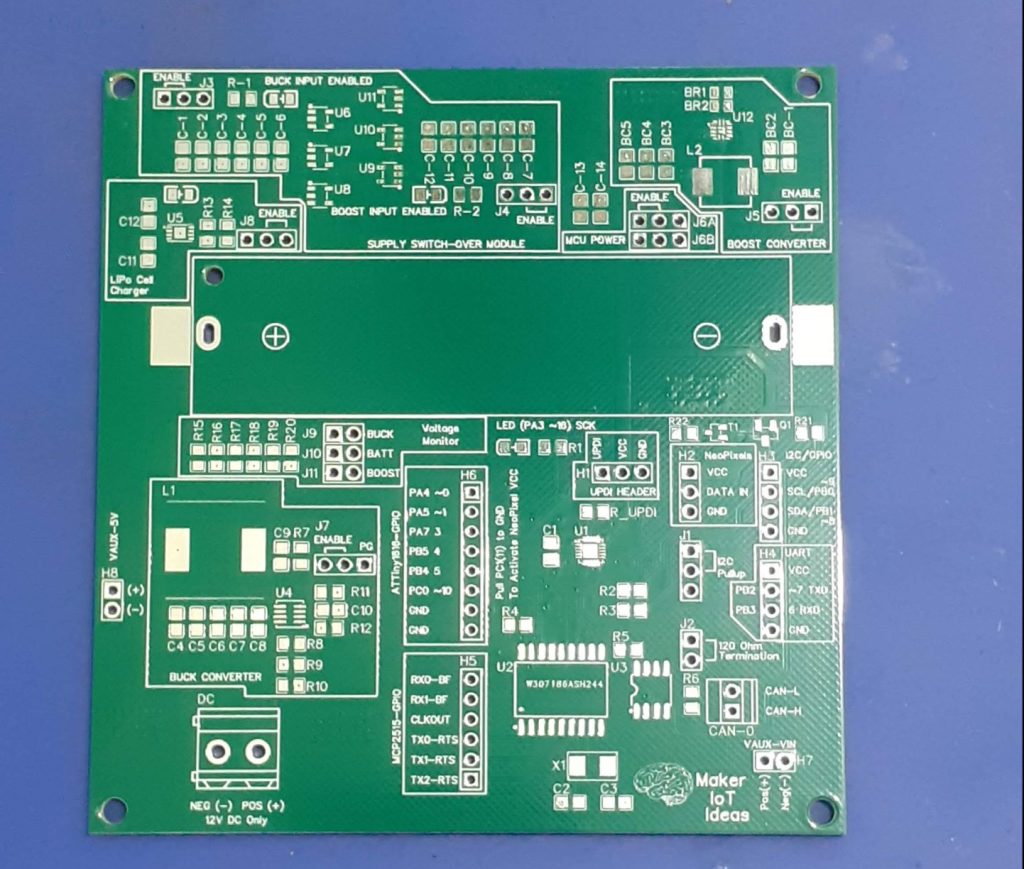

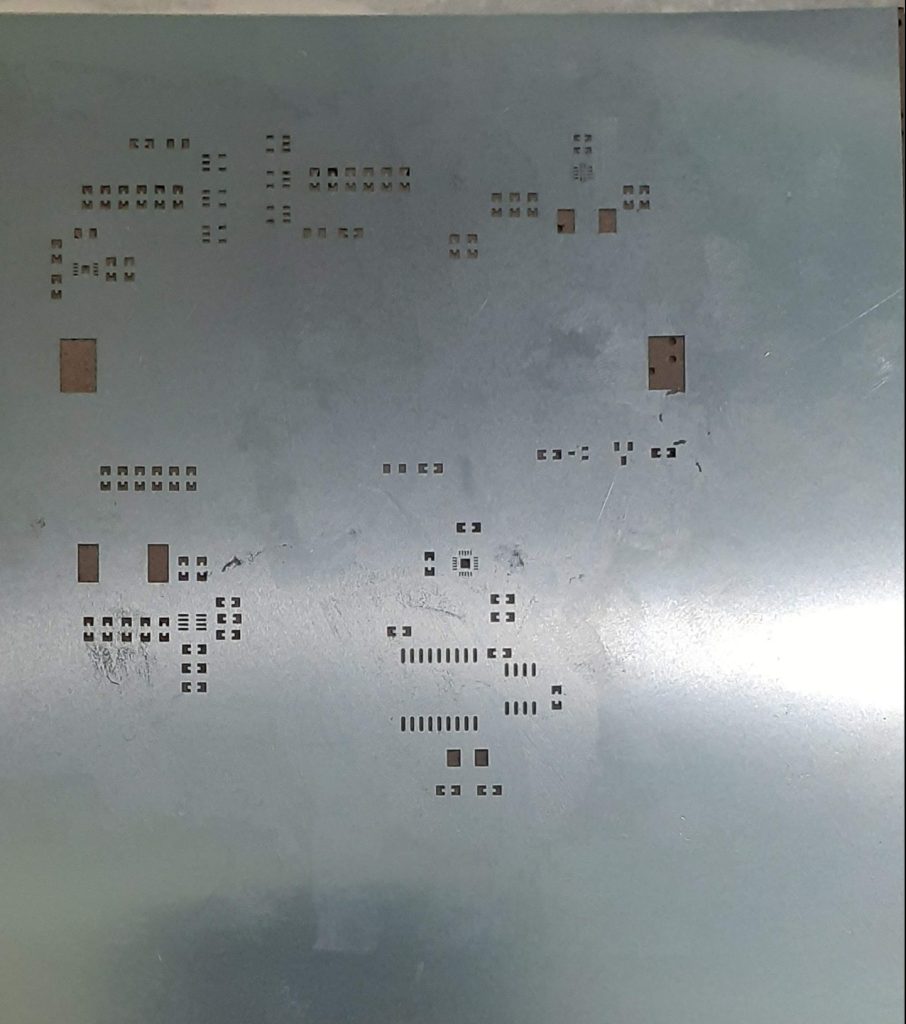

The bare PCB

The bare PCB

All of the circuit modules mentioned have been covered in detail in previous posts, so I will only briefly review some of them here to highlight some changes I have made to the original circuits.

The ideal diode supply or-ing circuit has been modified to use 3 ideal diode chips in parallel per “channel”. This is “experimental” from my point of view since I am unsure if it would actually perform as expected. I had to do this due to experiencing great difficulty in obtaining a suitable high-current component at a reasonable cost and in a suitable footprint.

This question remains unanswered, as I encountered a double whammy with no stock issue forcing me to use one device per channel. I shall update the performance of this experiment soon when I receive the back-ordered components.

The performance of the boost converter can at best be described as temperamental. This is definitively an assembly issue on my side, as the controller chip is tiny (approx. 2mm x 2mm with 14 leads), and hand assembly of this with a stencil and hot-plate reflow almost always results in the need to hot-air rework and then possibly damaging the chip with heat or other issues.

I am currently investigating an alternative chip to use in future versions of the PCB to remove this issue. When the circuit works, it is rock solid and gives great performance. Maybe someone from Microchip (#not sponsored) can give some advice here…

The Buck converter performs solidly as usual, great little device! No complaints there as usual.

The Lipo-cell charger performs as expected, with no issues to report.

As seen in the picture above, I have placed yellow jumpers to make it easy to enable/disable parts of the circuit to aid in testing and debugging. These help quite a lot.

The ATTiny 1616 is solid, as can be expected, and functions exactly as expected. Some users would have to replace the R_UPDI resistor with a 0ohm link, depending on which UPDI programmer you use. Since I use my own custom-made UPDI Programmer as recommended in a circuit by Spence Konde/Dr Izzy on his excellent megatinyCore documentation site, I have no issues with UPDI.

The Can-Bus hardware functions as expected, with no issues to report.

There is also an error on the silkscreen, Pin_PC1 should be pulled HIGH to activate the VCC line for the neoPixel strip, NOT LOW as printed on the silkscreen.

Manufacturing the PCB

I choose PCBWay for my PCB manufacturing. Why? What makes them different from the rest?

PCBWay‘s business goal is to be the most professional PCB manufacturer for prototyping and low-volume production work in the world. With more than a decade in the business, they are committed to meeting the needs of their customers from different industries in terms of quality, delivery, cost-effectiveness and any other demanding requests. As one of the most experienced PCB manufacturers and SMT Assemblers in China, they pride themselves to be our (the Makers) best business partners, as well as good friends in every aspect of our PCB manufacturing needs. They strive to make our R&D work easy and hassle-free.

How do they do that?

PCBWay is NOT a broker. That means that they do all manufacturing and assembly themselves, cutting out all the middlemen, and saving us money.

PCBWay’s online quoting system gives a very detailed and accurate picture of all costs upfront, including components and assembly costs. This saves a lot of time and hassle.

PCBWay gives you one-on-one customer support, that answers you in 5 minutes ( from the Website chat ), or by email within a few hours ( from your personal account manager). Issues are really resolved very quickly, not that there are many anyway, but, as we are all human, it is nice to know that when a gremlin rears its head, you have someone to talk to who will do his/her best to resolve your issue as soon as possible.

Find out more here

Assembly and Testing

Due to the size of some of the components on this PCB, a stencil is compulsory for hand assembly of this PCB, or even better, have it professionally assembled by your PCB manufacturer. It will save you a lot of headaches during assembly

The stencil that I got from PCBWAy made things so much easier

The stencil that I got from PCBWAy made things so much easier

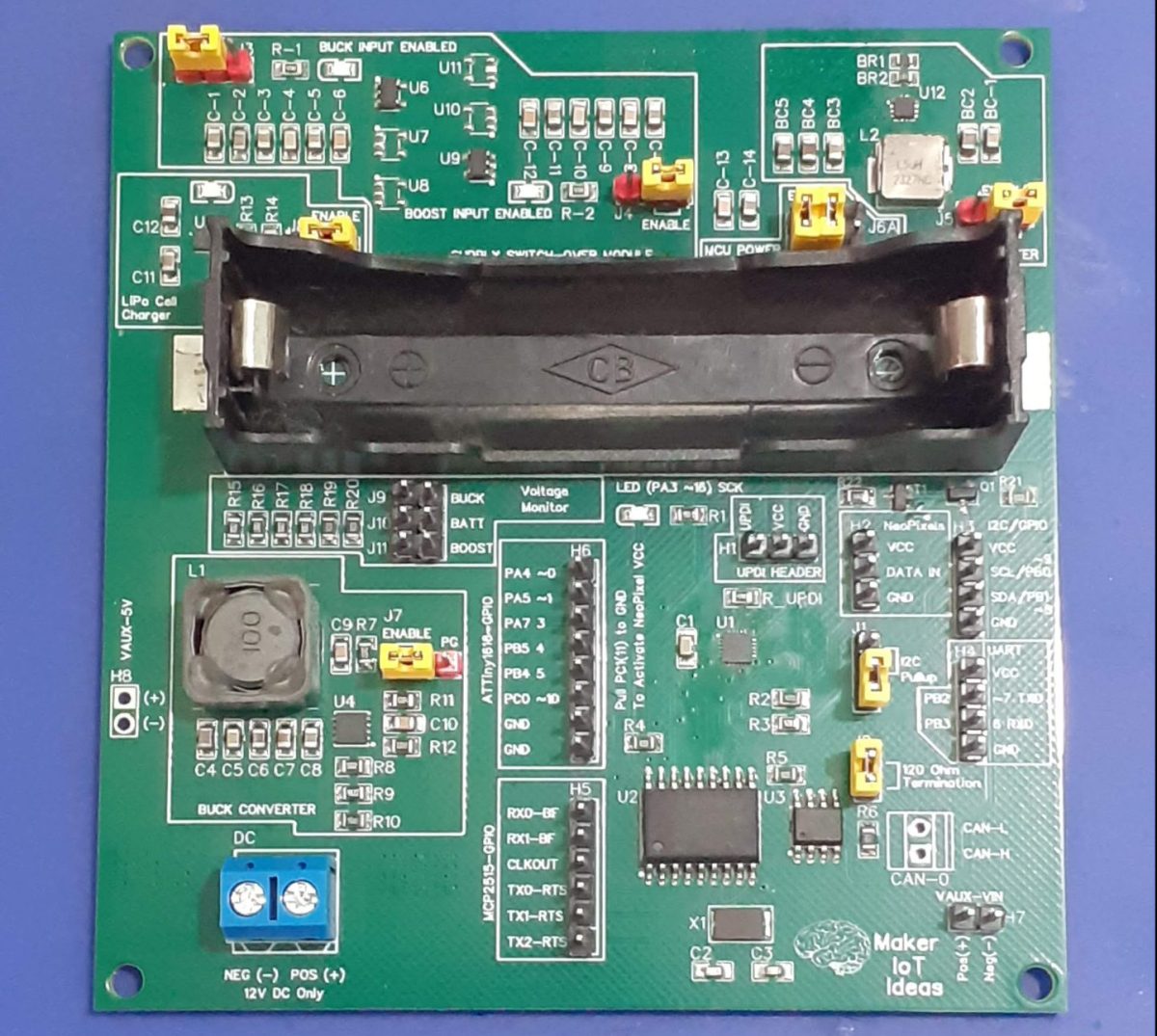

The assembled PCB, without CAN connector and Lipo Cell

The assembled PCB, without CAN connector and Lipo Cell

Conclusion

This project took way longer than initially planned, due to many issues including logistics, component availability, the need to rework some areas of the board, and being super busy at my day-job. The firmware is still a work in progress, with bits and pieces of code floating around, hacked together to test basic functionality but nothing else.

I hope to complete this project very shortly, and after a final revision of the hardware, to get rid of some issues that bug me, to have a very useable piece of equipment to finally install in my car as planned from the very beginning

ATTiny1616-LIGHT-Controller-with-CAN_B_PCB_ATTiny1616-LIGHT-Controller-with-C_2024-09-11

*PCBWay community is a sharing platform. We are not responsible for any design issues and parameter issues (board thickness, surface finish, etc.) you choose.

- Comments(0)

- Likes(0)

- 0 USER VOTES

- YOUR VOTE 0.00 0.00

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

More by Jean Redelinghuys MakerIoT2020

More by Jean Redelinghuys MakerIoT2020

-

PCB_MCP23008_2023-10-08

MCP23008 BreakoutI designed this breakout to assist me during prototyping my next version of the “RP...

PCB_MCP23008_2023-10-08

MCP23008 BreakoutI designed this breakout to assist me during prototyping my next version of the “RP...

-

PCB_XiaoRP2040-Mouse-REV2

Xiao RP2040 Joystick Mouse – revision 2.00Revision 1.0 of the ProjectOver the last few months, I hav...

PCB_XiaoRP2040-Mouse-REV2

Xiao RP2040 Joystick Mouse – revision 2.00Revision 1.0 of the ProjectOver the last few months, I hav...

-

Multi Purpose IO Card

Multi-Purpose IO CardWhen we are working on a prototype, we always need access to pushbuttons, encod...

Multi Purpose IO Card

Multi-Purpose IO CardWhen we are working on a prototype, we always need access to pushbuttons, encod...

-

Variable Voltage Power Module

Variable Voltage Power ModulePowering electronics projects are always challenging. This Variable vol...

Variable Voltage Power Module

Variable Voltage Power ModulePowering electronics projects are always challenging. This Variable vol...

-

I2C Matrix Keypad

An I2C Matrix KeypadThe completed I2C Matrix KeypadIn a previous post this month I introduced my 4×4...

I2C Matrix Keypad

An I2C Matrix KeypadThe completed I2C Matrix KeypadIn a previous post this month I introduced my 4×4...

-

ESP32-S Development Board, in "Arduino Uno" form factor

UPDATE 24/06/2023:This board now has a Hardware Revision 2.0 available. It is the same board but wit...

ESP32-S Development Board, in "Arduino Uno" form factor

UPDATE 24/06/2023:This board now has a Hardware Revision 2.0 available. It is the same board but wit...

-

W307186ASC94_Gerber_PCB_USB-Ports

USB Power Supply ModuleUSB Ports are quite handy to power all our day-to-day electronic devices, but...

W307186ASC94_Gerber_PCB_USB-Ports

USB Power Supply ModuleUSB Ports are quite handy to power all our day-to-day electronic devices, but...

-

Atmega 328P based PWM controller Card

ATMega 328P Based PWM controller CardAs part of my recent ESP-12E I2C Base Board project, I designed...

Atmega 328P based PWM controller Card

ATMega 328P Based PWM controller CardAs part of my recent ESP-12E I2C Base Board project, I designed...

-

W307186ASC71_Gerber_PCB_ESP-Now Remote

Today we will look at the remote control unit for the Robotic Toy Car – Part 6.The project is close ...

W307186ASC71_Gerber_PCB_ESP-Now Remote

Today we will look at the remote control unit for the Robotic Toy Car – Part 6.The project is close ...

-

W307186ASV69_Gerber_PCB_Robot-Car-MCU-Board Prototype

In our last project, we started working on repurposing an old toy car. In this part, Robot Toy Car –...

W307186ASV69_Gerber_PCB_Robot-Car-MCU-Board Prototype

In our last project, we started working on repurposing an old toy car. In this part, Robot Toy Car –...

-

W307186ASV62_Gerber_PCB_DUAL-H-Bridge

by makeriot2020 on May 27, 2022Many of us have old toys laying around the house, they belong to ou...

W307186ASV62_Gerber_PCB_DUAL-H-Bridge

by makeriot2020 on May 27, 2022Many of us have old toys laying around the house, they belong to ou...

-

CAN-BUS Breakout

Breadboard Compatible CAN-BUS Breakout ModuleWhat is this:Some of us have already used the commonly ...

CAN-BUS Breakout

Breadboard Compatible CAN-BUS Breakout ModuleWhat is this:Some of us have already used the commonly ...

-

RA-02 Breakout with Level converters

Breadboard and beginner-friendly RA-02 Breakout ModuleMost Makers and electronics enthusiasts may al...

RA-02 Breakout with Level converters

Breadboard and beginner-friendly RA-02 Breakout ModuleMost Makers and electronics enthusiasts may al...

-

ATMEGA328P Module with integrated LoRa and CAN Bus

ATMEGA328P Module with integrated LoRa and CAN-BUSINTRODUCTIONIn my quest to perfect my LoRa telemet...

ATMEGA328P Module with integrated LoRa and CAN Bus

ATMEGA328P Module with integrated LoRa and CAN-BUSINTRODUCTIONIn my quest to perfect my LoRa telemet...

-

Sx127x-Ra-02-Test-Module with ATMEGA328P-AU

SX127x LoRa/FSK/OOK Prototype Radio BoardI recently had a requirement to do some automation/telemetr...

Sx127x-Ra-02-Test-Module with ATMEGA328P-AU

SX127x LoRa/FSK/OOK Prototype Radio BoardI recently had a requirement to do some automation/telemetr...

-

USB-ASP Programmer ATMEGA8

Build your own USB-ASP Programmer CloneBymakeriot2020 FEB 21, 2022 Arduino, ASP programmerUsing mor...

USB-ASP Programmer ATMEGA8

Build your own USB-ASP Programmer CloneBymakeriot2020 FEB 21, 2022 Arduino, ASP programmerUsing mor...

-

ATTiny1616-LIGHT-Controller-with-CAN_B_PCB_ATTiny1616-LIGHT-Controller-with-C_2024-09-11

Assembly of the ATTiny1616 Can bus controller PCBThe Assembly of the ATTiny1616 Can Bus Controller P...

ATTiny1616-LIGHT-Controller-with-CAN_B_PCB_ATTiny1616-LIGHT-Controller-with-C_2024-09-11

Assembly of the ATTiny1616 Can bus controller PCBThe Assembly of the ATTiny1616 Can Bus Controller P...

-

ATTiny1616QFN-CAN-Remote-Neopixel-Ligh_PCB_ATTiny1616QFN-CAN-Remote-Neopixel-2024-09-11_2024-09-11

NeoPixel CAN-Bus Module with local controlAs part of my current project to add NeoPixels to the cabi...

ATTiny1616QFN-CAN-Remote-Neopixel-Ligh_PCB_ATTiny1616QFN-CAN-Remote-Neopixel-2024-09-11_2024-09-11

NeoPixel CAN-Bus Module with local controlAs part of my current project to add NeoPixels to the cabi...

-

-

mammoth-3D SLM Voron Toolhead – Manual Drill & Tap Edition

236 0 0 -

-

AEL-2011 Power Supply Module

764 0 2 -

AEL-2011 50W Power Amplifier

635 0 2 -

-

-

Custom Mechanical Keyboard

827 0 0 -

Tester for Touch Screen Digitizer without using microcontroller

452 2 2 -

Audio reactive glow LED wristband/bracelet with NFC / RFID-Tags

402 0 1 -

-