4-cell 18650 Charging Module

Low BOM cost 4-cell 18650 Charger

Due to their high capacity and relatively low cost, LiPo cells are almost everywhere these days. This Low BOM cost 4-cell 18650 Charger module is my attempt to solve another issue.

The 18650 Lipo cell is quite common in my lab, and for an excellent reason, as mentioned above, they are cost-effective and also store quite a bit of energy. recharging them after use has however been quite a lengthy exercise in the past.

The usual process involved a few Lipo Charging modules, all connected via USB cables, charging one cell at a time. This not only takes up quite a bit of time and space but also occupies USB ports that could be used for other purposes.

Based on the ultra-cheap TP4056 chip, these single-cell charging modules cost peanuts, but with the required wiring and battery holders, as well as the cables to supply power, it does not really look very neat. I have thus been looking for a better solution for quite a while now, and had quite a few requirements for my “ideal” module.

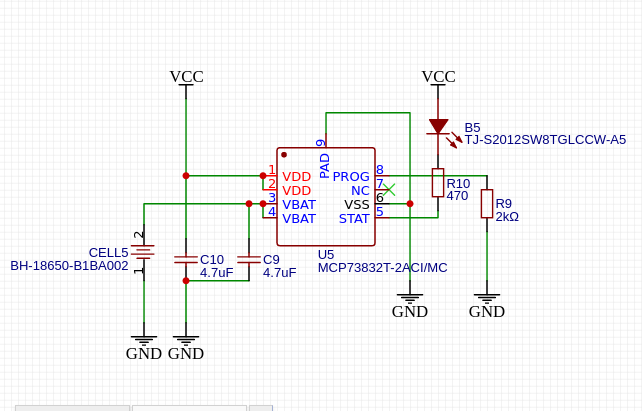

The MCP73832 from MICROCHIP seemed like a good choice for a custom design, as it requires only 5 additional external components, which are only two resistors, two capacitors and an led. The chip is also extremely low-cost.

High accuracy preset output voltage regulation (+/-0.75%)

Output voltage options include 4.2V, 4.35V, 4.4V and 4.5V

User-programmable charge current

Open-drain status output

On-chip thermal regulation

Preconditioning and end-of-charge ratio options

Under-voltage lockout

Includes integrated pass transistor, integrated current sensing, and reverse discharge protection in 5-pin SOT-23 and thermally-efficient 8-pin 2mm x 3mm DFN packages.

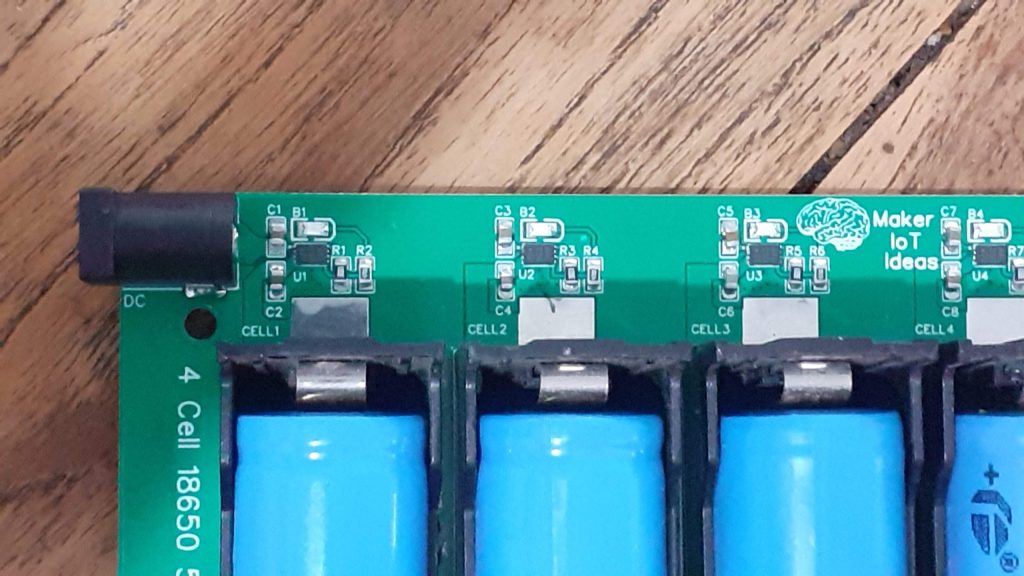

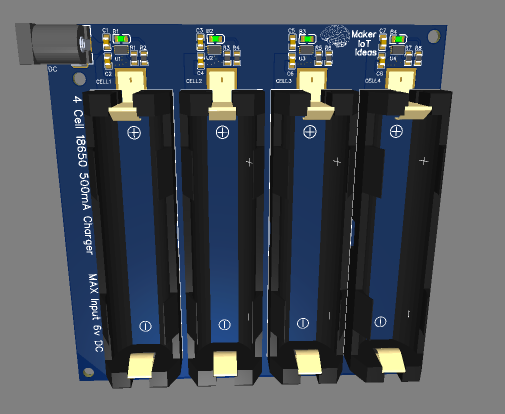

The Prototype Module

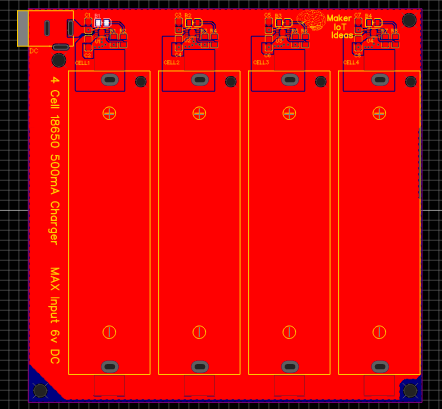

The design that I came up with, can charge 4-cell simultaneously. The maximum input voltage is limited to 6v DC.

Another interesting feature is the ability to use either through-hole battery holders or SMD ones. I did that because I have quite a few of the through-hole ones in stock, but as they were bought quite a while ago, the exact part number went on holiday. When having the module assembled in the factory,the SMD parts can be used, as there seems to be plenty in stock.

The Schematic

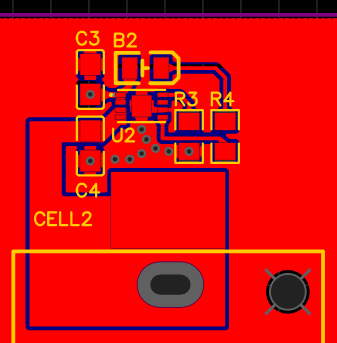

Because I enjoy a challenge, the design uses the smaller 3mm 2mm DFN8 package. Charging current is set with R9, which is 2k in this case, which will result in a charging current of the full 500mA. You can adjust it as per your requirements, to a value between 2k and 10k, as per the datasheet.

The full schematic is available here:

Schematic_Lipo-Cell-Charger_2023-04-24Download

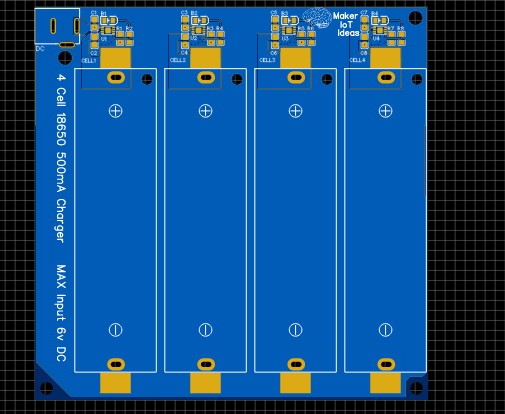

PCB Design

The PCB design was optimised to fit on a 10cm x 10cm board. Most of the board is made up of a solid copper pour to provide a good ground plane. Charging circuitry is placed as close together as possible, with a good connection of the thermal pad on the DFN8 package to the ground plane to help with thermal regulation. In this case, I have attempted to replicate the suggested reference design as closely as possible, while adapting it for use with the DFN8 package (Reference design uses the 5 lead SOT-23 package)

As seen in the close-up, components are placed as close as possible to the MCP73832, and via stitching are used to ensure a good connection to the ground, as well as allow the ground plane to serve as a heatsink.

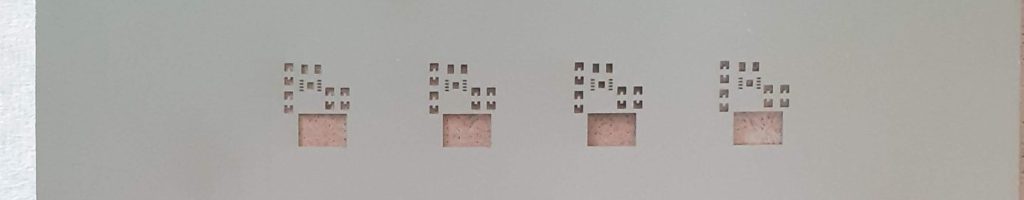

Assembly

Assembly of this module definitely requires the use of a stencil. The DFN-8 package of the IC is only 3mm x 2mm, and there are 8 leads as well as a thermal pad crammed in there. A stencil will ensure that you add just the correct amount of solder paste to each pad.

As we can clearly see in this cropped picture of the stencil, those pads are SUPER tiny.

I chose to use the hotplate, as well as some hot air for the SMD component assembly. The battery holders and DC barrel-connector are all through-hole, and were thus assembled using a standard soldering iron, with slightly thicker solder, and a bit more heat than normal, as the pads are quite big, and the big copper pour really sucks the heat away from the joints.

Testing

Testing the module went really well. I used four 18650 cells that needed recharging, and they were very quickly ( in about 1 hour ) charged to 4.20 volt.

The Charge Indicator LED on each charging circuit works in reverse from what we would normally expect, with it lighting up while charging, and going out when done.

The current draw (measured on the bench power supply) verified that each cell was charging at the 500mA as designed. The current draw also reduced as each cell charging cycle completed and eventually went down to very close to zero (The Ampere meter on my bench supply can not measure very low current with a lof of accuracy -:) )

Measuring each cell that have completed its charging cycle with a standard multimeter confirmed that they were indeed at 4.20v, and that the charging circuitry was no longer feeding current to any of them.

Drawing current out of a single cell (I used a set of clips ) to power a dummy load, resulted in an automatic recharge cycle being initiated once the cell voltage dropped past the set charging threshold.

It is however VERY important to note that this module is by NO means a balanced cell charger. It is a 4-way single cell charger that charges 4 cells independently from each other, at the same time. It is thus completely possible as well as probable that the four cells will/may be at slightly different voltages at the end of each respective charging cycle.

Conclusion

This project is most definitely high on the list of my most needed items. Keeping a bunch of 18650 cells charged and correctly maintained can be quite a chore, and the way that I have done it in the past was definitively not ideal.

It has also cost me quite a few cells that died way before their time.

Using this module, the chore of charging these cells will be reduced by a lot, and hopefully, in the future, I will come up with a solution to augment this module so that I can have these cells on a semi-permanent charge, with monitoring and only charging those cells that needs it.

4-cell 18650 Charging Module

*PCBWay community is a sharing platform. We are not responsible for any design issues and parameter issues (board thickness, surface finish, etc.) you choose.

Raspberry Pi 5 7 Inch Touch Screen IPS 1024x600 HD LCD HDMI-compatible Display for RPI 4B 3B+ OPI 5 AIDA64 PC Secondary Screen(Without Speaker)

BUY NOW

ESP32-S3 4.3inch Capacitive Touch Display Development Board, 800×480, 5-point Touch, 32-bit LX7 Dual-core Processor

BUY NOW

Raspberry Pi 5 7 Inch Touch Screen IPS 1024x600 HD LCD HDMI-compatible Display for RPI 4B 3B+ OPI 5 AIDA64 PC Secondary Screen(Without Speaker)

BUY NOW- Comments(0)

- Likes(2)

Log in to post comments.

Log in to post comments.

-

Jakub Jakub

Apr 30,2023

Jakub Jakub

Apr 30,2023

-

Engineer

Apr 29,2023

Engineer

Apr 29,2023

- 0 USER VOTES

- YOUR VOTE 0.00 0.00

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

More by Jean Redelinghuys MakerIoT2020

More by Jean Redelinghuys MakerIoT2020

-

RA-02 Breakout with Level converters

Breadboard and beginner-friendly RA-02 Breakout ModuleMost Makers and electronics enthusiasts may al...

RA-02 Breakout with Level converters

Breadboard and beginner-friendly RA-02 Breakout ModuleMost Makers and electronics enthusiasts may al...

-

ATMEGA328P Module with integrated LoRa and CAN Bus

ATMEGA328P Module with integrated LoRa and CAN-BUSINTRODUCTIONIn my quest to perfect my LoRa telemet...

ATMEGA328P Module with integrated LoRa and CAN Bus

ATMEGA328P Module with integrated LoRa and CAN-BUSINTRODUCTIONIn my quest to perfect my LoRa telemet...

-

Sx127x-Ra-02-Test-Module with ATMEGA328P-AU

SX127x LoRa/FSK/OOK Prototype Radio BoardI recently had a requirement to do some automation/telemetr...

Sx127x-Ra-02-Test-Module with ATMEGA328P-AU

SX127x LoRa/FSK/OOK Prototype Radio BoardI recently had a requirement to do some automation/telemetr...

-

USB-ASP Programmer ATMEGA8

Build your own USB-ASP Programmer CloneBymakeriot2020 FEB 21, 2022 Arduino, ASP programmerUsing mor...

USB-ASP Programmer ATMEGA8

Build your own USB-ASP Programmer CloneBymakeriot2020 FEB 21, 2022 Arduino, ASP programmerUsing mor...

-

ATTiny1616-LIGHT-Controller-with-CAN_B_PCB_ATTiny1616-LIGHT-Controller-with-C_2024-09-11

Assembly of the ATTiny1616 Can bus controller PCBThe Assembly of the ATTiny1616 Can Bus Controller P...

ATTiny1616-LIGHT-Controller-with-CAN_B_PCB_ATTiny1616-LIGHT-Controller-with-C_2024-09-11

Assembly of the ATTiny1616 Can bus controller PCBThe Assembly of the ATTiny1616 Can Bus Controller P...

-

ATTiny1616QFN-CAN-Remote-Neopixel-Ligh_PCB_ATTiny1616QFN-CAN-Remote-Neopixel-2024-09-11_2024-09-11

NeoPixel CAN-Bus Module with local controlAs part of my current project to add NeoPixels to the cabi...

ATTiny1616QFN-CAN-Remote-Neopixel-Ligh_PCB_ATTiny1616QFN-CAN-Remote-Neopixel-2024-09-11_2024-09-11

NeoPixel CAN-Bus Module with local controlAs part of my current project to add NeoPixels to the cabi...

-

PCB_MCP23008_2023-10-08

MCP23008 BreakoutI designed this breakout to assist me during prototyping my next version of the “RP...

PCB_MCP23008_2023-10-08

MCP23008 BreakoutI designed this breakout to assist me during prototyping my next version of the “RP...

-

PCB_XiaoRP2040-Mouse-REV2

Xiao RP2040 Joystick Mouse – revision 2.00Revision 1.0 of the ProjectOver the last few months, I hav...

PCB_XiaoRP2040-Mouse-REV2

Xiao RP2040 Joystick Mouse – revision 2.00Revision 1.0 of the ProjectOver the last few months, I hav...

-

Multi Purpose IO Card

Multi-Purpose IO CardWhen we are working on a prototype, we always need access to pushbuttons, encod...

Multi Purpose IO Card

Multi-Purpose IO CardWhen we are working on a prototype, we always need access to pushbuttons, encod...

-

Variable Voltage Power Module

Variable Voltage Power ModulePowering electronics projects are always challenging. This Variable vol...

Variable Voltage Power Module

Variable Voltage Power ModulePowering electronics projects are always challenging. This Variable vol...

-

I2C Matrix Keypad

An I2C Matrix KeypadThe completed I2C Matrix KeypadIn a previous post this month I introduced my 4×4...

I2C Matrix Keypad

An I2C Matrix KeypadThe completed I2C Matrix KeypadIn a previous post this month I introduced my 4×4...

-

ESP32-S Development Board, in "Arduino Uno" form factor

UPDATE 24/06/2023:This board now has a Hardware Revision 2.0 available. It is the same board but wit...

ESP32-S Development Board, in "Arduino Uno" form factor

UPDATE 24/06/2023:This board now has a Hardware Revision 2.0 available. It is the same board but wit...

-

W307186ASC94_Gerber_PCB_USB-Ports

USB Power Supply ModuleUSB Ports are quite handy to power all our day-to-day electronic devices, but...

W307186ASC94_Gerber_PCB_USB-Ports

USB Power Supply ModuleUSB Ports are quite handy to power all our day-to-day electronic devices, but...

-

Atmega 328P based PWM controller Card

ATMega 328P Based PWM controller CardAs part of my recent ESP-12E I2C Base Board project, I designed...

Atmega 328P based PWM controller Card

ATMega 328P Based PWM controller CardAs part of my recent ESP-12E I2C Base Board project, I designed...

-

W307186ASC71_Gerber_PCB_ESP-Now Remote

Today we will look at the remote control unit for the Robotic Toy Car – Part 6.The project is close ...

W307186ASC71_Gerber_PCB_ESP-Now Remote

Today we will look at the remote control unit for the Robotic Toy Car – Part 6.The project is close ...

-

W307186ASV69_Gerber_PCB_Robot-Car-MCU-Board Prototype

In our last project, we started working on repurposing an old toy car. In this part, Robot Toy Car –...

W307186ASV69_Gerber_PCB_Robot-Car-MCU-Board Prototype

In our last project, we started working on repurposing an old toy car. In this part, Robot Toy Car –...

-

W307186ASV62_Gerber_PCB_DUAL-H-Bridge

by makeriot2020 on May 27, 2022Many of us have old toys laying around the house, they belong to ou...

W307186ASV62_Gerber_PCB_DUAL-H-Bridge

by makeriot2020 on May 27, 2022Many of us have old toys laying around the house, they belong to ou...

-

CAN-BUS Breakout

Breadboard Compatible CAN-BUS Breakout ModuleWhat is this:Some of us have already used the commonly ...

CAN-BUS Breakout

Breadboard Compatible CAN-BUS Breakout ModuleWhat is this:Some of us have already used the commonly ...

-

RA-02 Breakout with Level converters

Breadboard and beginner-friendly RA-02 Breakout ModuleMost Makers and electronics enthusiasts may al...

RA-02 Breakout with Level converters

Breadboard and beginner-friendly RA-02 Breakout ModuleMost Makers and electronics enthusiasts may al...

-

ATMEGA328P Module with integrated LoRa and CAN Bus

ATMEGA328P Module with integrated LoRa and CAN-BUSINTRODUCTIONIn my quest to perfect my LoRa telemet...

ATMEGA328P Module with integrated LoRa and CAN Bus

ATMEGA328P Module with integrated LoRa and CAN-BUSINTRODUCTIONIn my quest to perfect my LoRa telemet...

-

Sx127x-Ra-02-Test-Module with ATMEGA328P-AU

SX127x LoRa/FSK/OOK Prototype Radio BoardI recently had a requirement to do some automation/telemetr...

Sx127x-Ra-02-Test-Module with ATMEGA328P-AU

SX127x LoRa/FSK/OOK Prototype Radio BoardI recently had a requirement to do some automation/telemetr...

-

USB-ASP Programmer ATMEGA8

Build your own USB-ASP Programmer CloneBymakeriot2020 FEB 21, 2022 Arduino, ASP programmerUsing mor...

USB-ASP Programmer ATMEGA8

Build your own USB-ASP Programmer CloneBymakeriot2020 FEB 21, 2022 Arduino, ASP programmerUsing mor...

-

ATTiny1616-LIGHT-Controller-with-CAN_B_PCB_ATTiny1616-LIGHT-Controller-with-C_2024-09-11

Assembly of the ATTiny1616 Can bus controller PCBThe Assembly of the ATTiny1616 Can Bus Controller P...

ATTiny1616-LIGHT-Controller-with-CAN_B_PCB_ATTiny1616-LIGHT-Controller-with-C_2024-09-11

Assembly of the ATTiny1616 Can bus controller PCBThe Assembly of the ATTiny1616 Can Bus Controller P...

-

ATTiny1616QFN-CAN-Remote-Neopixel-Ligh_PCB_ATTiny1616QFN-CAN-Remote-Neopixel-2024-09-11_2024-09-11

NeoPixel CAN-Bus Module with local controlAs part of my current project to add NeoPixels to the cabi...

ATTiny1616QFN-CAN-Remote-Neopixel-Ligh_PCB_ATTiny1616QFN-CAN-Remote-Neopixel-2024-09-11_2024-09-11

NeoPixel CAN-Bus Module with local controlAs part of my current project to add NeoPixels to the cabi...

-

PCB_MCP23008_2023-10-08

MCP23008 BreakoutI designed this breakout to assist me during prototyping my next version of the “RP...

PCB_MCP23008_2023-10-08

MCP23008 BreakoutI designed this breakout to assist me during prototyping my next version of the “RP...

-

PCB_XiaoRP2040-Mouse-REV2

Xiao RP2040 Joystick Mouse – revision 2.00Revision 1.0 of the ProjectOver the last few months, I hav...

PCB_XiaoRP2040-Mouse-REV2

Xiao RP2040 Joystick Mouse – revision 2.00Revision 1.0 of the ProjectOver the last few months, I hav...

-

Multi Purpose IO Card

Multi-Purpose IO CardWhen we are working on a prototype, we always need access to pushbuttons, encod...

Multi Purpose IO Card

Multi-Purpose IO CardWhen we are working on a prototype, we always need access to pushbuttons, encod...

-

Variable Voltage Power Module

Variable Voltage Power ModulePowering electronics projects are always challenging. This Variable vol...

Variable Voltage Power Module

Variable Voltage Power ModulePowering electronics projects are always challenging. This Variable vol...

-

I2C Matrix Keypad

An I2C Matrix KeypadThe completed I2C Matrix KeypadIn a previous post this month I introduced my 4×4...

I2C Matrix Keypad

An I2C Matrix KeypadThe completed I2C Matrix KeypadIn a previous post this month I introduced my 4×4...

-

ESP32-S Development Board, in "Arduino Uno" form factor

UPDATE 24/06/2023:This board now has a Hardware Revision 2.0 available. It is the same board but wit...

ESP32-S Development Board, in "Arduino Uno" form factor

UPDATE 24/06/2023:This board now has a Hardware Revision 2.0 available. It is the same board but wit...

-

Commodore 64 1541-II 1581 Floppy Disk Drive C64 Power Supply Unit USB-C 5V 12V DIN connector 5.25

161 1 3 -

Easy to print simple stacking organizer with drawers

87 0 0 -

-

-

-

Modifying a Hotplate to a Reflow Solder Station

1135 1 6 -

MPL3115A2 Barometric Pressure, Altitude, and Temperature Sensor

637 0 1 -

-

Nintendo 64DD Replacement Shell

494 0 2 -

V2 Commodore AMIGA USB-C Power Sink Delivery High Efficiency Supply Triple Output 5V ±12V OLED display ATARI compatible shark 100W

1438 4 3