Arduino Based Concrete Clock With Touchless Night Lamp

When you mix creativity with electronics, it becomes a masterpiece.

Producing something original and worthwhile leads to the creation of a number of great new useful household products.

In this video, I am going to show you guys how to create this Arduino based touchless concrete clock.

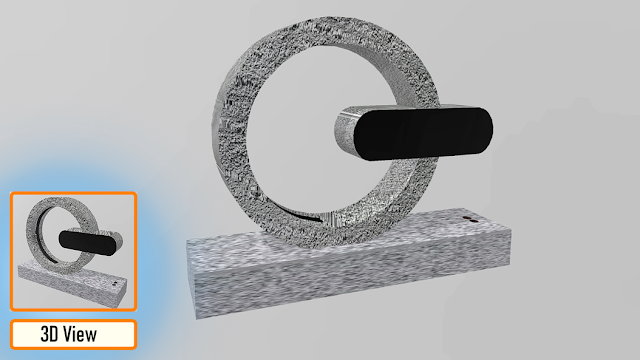

3D Design

I always love to generate a 3D model of my product before creating it in real. This not only gives me a better view of what the final product is going to look like, but also helps me in finding the correct measurements of the final product. So, I went ahead and used the free "Windows 3D-builder" to generate this 3D model.

The onscreen, black bar is where the TM1637 Digital Clock Module will sit. The gap in the circular concrete frame will house the 5 Blue LEDs that can be turned on or off my moving your hand over the IR Module.

These two holes are for the IR Sensor Module. The concrete base bar will house all the remaining electronics components in it.

The Template

Based on my 3D-Model I designed this 2D-Template.

You can download the template from the link provided in the description below and print it on a A4 paper.

Template: Download

Schematic Diagram

Before going ahead, lets have a look at the schematic diagram of the digital clock. The heart of this circuit is an Arduino Nano.

The TM1637 Digital Clock Module connects to D4 and D5 pin of the Arduino.

The DS1302 RTC Module connects to the A1, A2 and A3 pin of the Arduino.

The two White LEDs displayed on both sides of the digital clock connects to the D11 pin of the Arduino. These two LEDs flash 3 times every hour when the minutes counter is reset to "00".

The IR module is connected to the D6 pin of the Arduino and controls the blue cluster of LEDs connected to D12 pin of the Arduino.

My initial plan was to have 2 to 3 push button switches connected to D2 and D3 pin of Arduino to set the time of the clock. However in the final version, I did that by adding an extra line of code to my program. I will explain this in full details when we discuss the code.

Preparing The Top - Concrete

Using cardboard I created all the concrete molds. Cardboard was my first choice as it is very easy for me to cut and bend it into any shape of my choice.

These holes in the mold you see are for the ribbon cables.

Sticking this semi-circular piece on the left side of the inner circle will create the gap for the blue LED cluster when we pore the concrete into the mold.

Alright, so this is how it looks like after putting all the pieces of cardboard mold together. Now, lets pour some "Brickies Sand" in-and-around the mold to hold it nice and tight when I pour the liquid concrete. Making the sand a bit wet, will make it firm and will also remove all the unwanted air from the sand.

Cool, now lets go ahead and pour the concrete into the mold. Don't forget to compress the concrete mixture as you pour it. This way the concrete will reach all the necessary places and will also remove the unwanted air bubble from the mixture.

I also added few "Nails" inside the mixture to give it a bit more firmness. This step was absolutely necessary, as my first design completely collapsed because it was not very sturdy.

Once the setup dried up I removed all the sand and extracted the piece of art from it.

Preparing The Top - Electronics

Alright, now lets start installing the electronic components to the top section of the clock.

The 4-Digit LED clock module will sit inside this gap. I will cover it up using a black plastic film which I extracted from a wrapping paper.

For the back, I am using a compressed wood board. Based on my initial design I am going to make some holes in the board and install 3 x push button switches to it.

The blue LED cluster will be hot-glued in the gap at the back of the circular section.

I used a plastic cutout from a milk bottle to cover the Blue LED clusters. The white color of the plastic gave it a gloomy look, which was absolutely super awesome.

I hot glues the two white LEDs to the backplate before putting it against the concrete.

Frankly speaking, it was an absolute challenge for me to hot-glue the backplate on the camera. After struggling for a bit, I did that properly behind the scene.

Preparing The Base - Concrete

Now that we are done with the top section, lets start working on the base of the clock.

For the base, I prepared 2 x cardboard boxes with open top one slightly shorter in height than the other. The 2 x straws you see on-screen will create the hole for the IR module. The hole on the side is for the AC power cable.

The cardboard block I just added is to create a hole on the top of the base, where the circular-top will sit.

Then it was just a matter of pouring the sand inside and outside of the cardboard molds followed by pouring the concrete mixture into it.

Same as before I added some nails to give the structure some additional firmness.

Once the concrete dried up, I extracted the concrete base from the sand and carefully sanded the structure to give it a nice and smooth texture.

Preparing The Base - Electronics

Okie-dokie, now lets install the rest of the electronic components inside the base of the clock. I used the same compressed wooden board to create the baseplate and then one by one soldered and hot-glued all the electronics components to it. The IR module I used in this project is one of my self made DIY IR modules. If you want to know more about the module, please checkout my Tutorial No 21 - All About IR Modules and how to make your own DIY IR Module.

Joining The Base To The Top

Now that we have top and the bottom ready, lets go ahead and join them together.

I created this cardboard thing to hold the concrete, when I pour the concert in the hole. This cardboard block will also prevent me from poring excessive concrete inside the hole. The flap in the middle is to hold the wires preventing them from getting mixed up with the concrete. After pouring the concrete I left it of drying for almost 2 days.

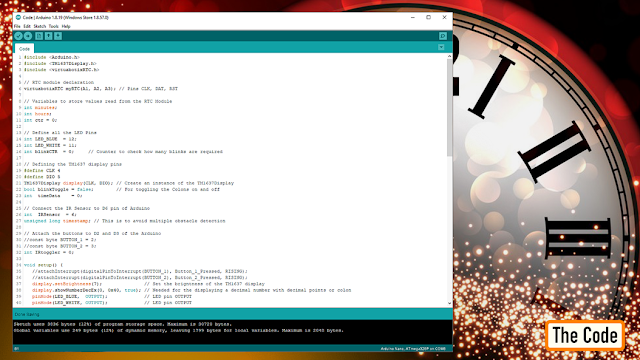

Code

While the concrete was drying up, I complied and uploaded the code to the Arduino.

For this project you need include the "ArduinoRTClibrary" and the "TM1637Display" libraries in your code. You can download them from github from the link provided in the description below.

Lets start the code by creating an instance of the RTC module followed by defining the variables used by the RTC module.

Then, define all the LED pins followed by creating an instance of the TM1637 module and defining all the variables used by the module.

Next, define the pins used by the IR module.

In the setup section, the 1st two lines can be used to attach an interrupt to the code, if you are planning to use the push button switches. However, in my code I am not using the buttons, so I commented them out.

Next, I have set the brightness of the display to the max value = 7 and added the "showNumberDecEx" function to include the colon in the code.

Next, I defined all the pin modes used by the attached components in the code.

The code below can be used to set the time of the clock. Set the correct time, uncomment and then load the code. Once loaded, comment the lines and then load the rest of the code.

// Set the current date, and time in the following format: // seconds, minutes, hours, day of the week, day of the month, month, year //myRTC.setDS1302Time(00, 39, 21, 7, 20, 1, 2023);

In the loop section, all we are doing is - reading the hour and minutes from the RTC module and displaying it on the 7-Segment display.

myRTC.updateTime(); // This allows for the update of variables for time or accessing the individual elements minutes = myRTC.minutes; // Get the current minutes from the RTC Module hours = myRTC.hours; // Get the current hours from the RTC Modules timeData = hours * 100 + minutes;

This code block is used to toggle the colon on and off.

// Code block that blinks the colon of the TM1637 module if (ctr == 200) { if (blinkToggle) { display.showNumberDecEx(timeData, 0x40, true); blinkToggle = false; } else { display.showNumberDecEx(timeData, 0, true); blinkToggle = true; }; ctr = 0; };ctr++; delay(5);

This section is used to read the value of the IR sensor and either turn on or turn off the blue LED clusters.

// Code block that turns on or off the Blue LED Cluster int Sensordata = digitalRead(IRSensor); // Set the GPIO as Input if (Sensordata != 0) { if (millis() - timestamp>500) { // This is to avoid multiple obstacle detection timestamp = millis(); if (IRtoggler == 0) {digitalWrite(LED_BLUE, HIGH);IRtoggler = 1;} else {digitalWrite(LED_BLUE, LOW); IRtoggler = 0;} }; };

This bit of the code, is to flash the white led when the minute counter resets to 0.

// Flash the white LEDs if minutes = 0 if ((int)minutes == 0) { if (blinkCTR==0 || blinkCTR==40 || blinkCTR==100 || blinkCTR==140 || blinkCTR==200 || blinkCTR==240 || blinkCTR==300 || blinkCTR==340) digitalWrite(LED_WHITE, HIGH); if (blinkCTR==20 || blinkCTR==60 || blinkCTR==120 || blinkCTR==160 || blinkCTR==220 || blinkCTR==260 || blinkCTR==320 || blinkCTR==360) digitalWrite(LED_WHITE, LOW); blinkCTR++; }; if ((int)minutes == 1) blinkCTR = 0; // Reset blinkCTR for the next cycle of flashing

If you are planning to use the 2 x push button switches to set the time or to set an alarm, go ahead and uncomment this bit of the code and add your code block to it.

// Pressing this button puts the clock in setup mode//void Button_1_Pressed(){};// Pressing this button increments the values on the display//void Button_2_Pressed(){};

Final Demo

So this is how it finally looks like.

Do comment and let me know if there are any scopes of improvement.

Thanks

Thanks again for checking my post. I hope it helps you.

If you want to support me subscribe to my YouTube Channel: https://www.youtube.com/user/tarantula3

Video: https://youtu.be/AQhBpQrfmg8

Full Blog Post: https://diy-projects4u.blogspot.com/2023/02/ArduinoClock.html

Other Links:

Template: Download

3D Model: Download

Github: Visit

ArduinoRTClibrary: Download

TM1637Display Library: Download

Support My Work:

BTC: 1Hrr83W2zu2hmDcmYqZMhgPQ71oLj5b7v5

LTC: LPh69qxUqaHKYuFPJVJsNQjpBHWK7hZ9TZ

DOGE: DEU2Wz3TK95119HMNZv2kpU7PkWbGNs9K3

ETH: 0xD64fb51C74E0206cB6702aB922C765c68B97dCD4

BAT: 0x9D9E77cA360b53cD89cc01dC37A5314C0113FFc3

LBC: bZ8ANEJFsd2MNFfpoxBhtFNPboh7PmD7M2

COS: bnb136ns6lfw4zs5hg4n85vdthaad7hq5m4gtkgf23 Memo: 572187879

BNB: 0xD64fb51C74E0206cB6702aB922C765c68B97dCD4

MATIC: 0xD64fb51C74E0206cB6702aB922C765c68B97dCD4

Thanks, ca again in my next tutorial.

Arduino Based Concrete Clock With Touchless Night Lamp

- Comments(0)

- Likes(1)

-

Dmitriy Krupin

Jul 31,2025

Dmitriy Krupin

Jul 31,2025

- 0 USER VOTES

- YOUR VOTE 0.00 0.00

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

More by Ashish Adhikari

More by Ashish Adhikari

-

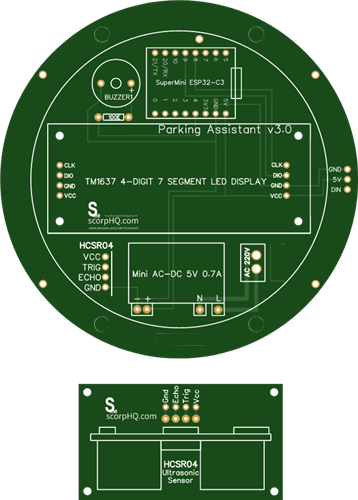

Arduino Parking Assistant V3

The ESP32-C3 Based Parking Assistant is an advanced parking sensor system that utilizes the ESP32-C3...

Arduino Parking Assistant V3

The ESP32-C3 Based Parking Assistant is an advanced parking sensor system that utilizes the ESP32-C3...

-

100 LED Chaser Circuit Using IC555 and CD4017

A Chaser Circuit consists of a clocked IC or other electronic unit like an Arduino that drives an ar...

100 LED Chaser Circuit Using IC555 and CD4017

A Chaser Circuit consists of a clocked IC or other electronic unit like an Arduino that drives an ar...

-

Cute Medusa 3D Printed Humidifier

Humidifiers add moisture to the air. They can help people with dry skin, allergies, and respiratory ...

Cute Medusa 3D Printed Humidifier

Humidifiers add moisture to the air. They can help people with dry skin, allergies, and respiratory ...

-

4x4x4 PCB LED CUBE

Note from PCBWay: This project includes two PCBs, if both need to be produced, please inform your sa...

4x4x4 PCB LED CUBE

Note from PCBWay: This project includes two PCBs, if both need to be produced, please inform your sa...

-

Getting Started With Raspberry Pi Pico

Couple of months ago, I bought a "Raspberry Pi Pico" to get some hands-on experience of it and to cr...

Getting Started With Raspberry Pi Pico

Couple of months ago, I bought a "Raspberry Pi Pico" to get some hands-on experience of it and to cr...

-

Make Your Own 3D Printed Diwali Diyas at Home

Diyas are the heart of major Indian festivals, most notably Diwali, the "Festival of Lights." Lighti...

Make Your Own 3D Printed Diwali Diyas at Home

Diyas are the heart of major Indian festivals, most notably Diwali, the "Festival of Lights." Lighti...

-

Arduino Based 3D Printed Color Adjustable Minecraft Lantern

For this Halloween, I'm fusing the creative blocky world of Minecraft with the spooky glow of the co...

Arduino Based 3D Printed Color Adjustable Minecraft Lantern

For this Halloween, I'm fusing the creative blocky world of Minecraft with the spooky glow of the co...

-

3D Printed Breathing IC555 LED Trophy

This project features a custom 3D-printed 'Mortal Kombat' trophy shell paired with a basic NE555 tim...

3D Printed Breathing IC555 LED Trophy

This project features a custom 3D-printed 'Mortal Kombat' trophy shell paired with a basic NE555 tim...

-

Destiny Internet Ghost - Internet Notifier

The Internet has changed the way we live our lives. From communication, education, banking, entertai...

Destiny Internet Ghost - Internet Notifier

The Internet has changed the way we live our lives. From communication, education, banking, entertai...

-

Liquid level indicator Using ULN2003

A water level indicator detects and indicates the level of water in an overhead tank and relays the ...

Liquid level indicator Using ULN2003

A water level indicator detects and indicates the level of water in an overhead tank and relays the ...

-

All About IC UNL2003

The UNL2003 IC contains 7 High Voltage, High Current NPN Darlington Transistor Arrays each rated at ...

All About IC UNL2003

The UNL2003 IC contains 7 High Voltage, High Current NPN Darlington Transistor Arrays each rated at ...

-

NodeMCU Based: 3D Printed Indoor Gauge Thermometer

Had some time this weekend and a desire to create something new and interesting, so went ahead and c...

NodeMCU Based: 3D Printed Indoor Gauge Thermometer

Had some time this weekend and a desire to create something new and interesting, so went ahead and c...

-

Rechargeable Gothic Lantern

A Gothic Lantern is a captivating piece of lighting that brings the allure of the Victorian Era into...

Rechargeable Gothic Lantern

A Gothic Lantern is a captivating piece of lighting that brings the allure of the Victorian Era into...

-

555 Adjustable Delay On Off Timer Circuit

The 555 timer IC is an integrated circuit (IC) that is used in a variety of timer, delay, pulse gene...

555 Adjustable Delay On Off Timer Circuit

The 555 timer IC is an integrated circuit (IC) that is used in a variety of timer, delay, pulse gene...

-

3D Printed Arduino Halloween Décor

When the full moon is shining and the wolves are howling, it's time for Halloween's spooky spectacle...

3D Printed Arduino Halloween Décor

When the full moon is shining and the wolves are howling, it's time for Halloween's spooky spectacle...

-

All About RCWL-0516 Microwave Radar Motion Sensor

Proximity sensing is a very common application in electronics.There are several ways to accomplish t...

All About RCWL-0516 Microwave Radar Motion Sensor

Proximity sensing is a very common application in electronics.There are several ways to accomplish t...

-

Transformers PCB BADGE

It's been a while, the Autobots have appeared on the silver screen. Finally they are returning to th...

Transformers PCB BADGE

It's been a while, the Autobots have appeared on the silver screen. Finally they are returning to th...

-

LED Fader Using 555 Timer IC

LED Fader Using 555 Timer ICWanted to generate a LED fading effect (fade-in and fade-out) for my upc...

LED Fader Using 555 Timer IC

LED Fader Using 555 Timer ICWanted to generate a LED fading effect (fade-in and fade-out) for my upc...

-

-

AEL-2011 Power Supply Module

553 0 2 -

AEL-2011 50W Power Amplifier

512 0 2 -

-

-

Custom Mechanical Keyboard

710 0 0 -

Tester for Touch Screen Digitizer without using microcontroller

340 2 2 -

Audio reactive glow LED wristband/bracelet with NFC / RFID-Tags

322 0 1 -

-

-