|

|

555 Timer IC |

x 1 | |

|

|

47KΩ Resistor |

x 1 | |

|

|

220Ω Resistor |

x 1 | |

|

|

BC548 NPN Transistor |

x 1 | |

|

|

33µF Capacitor |

x 1 | |

|

|

LED |

x 2 |

|

arduino IDEArduino

|

Transformers PCB BADGE

It's been a while, the Autobots have appeared on the silver screen. Finally they are returning to the big screen in their upcoming Transformers movie "Rise of the Beasts".

This inspired me in making a PCB Badge to complement my enthusiasm and love towards the Autobots.

In this tutorial, I am going to show you guys how to design this "Transformers PCB Badge" and how to solder the components to it.

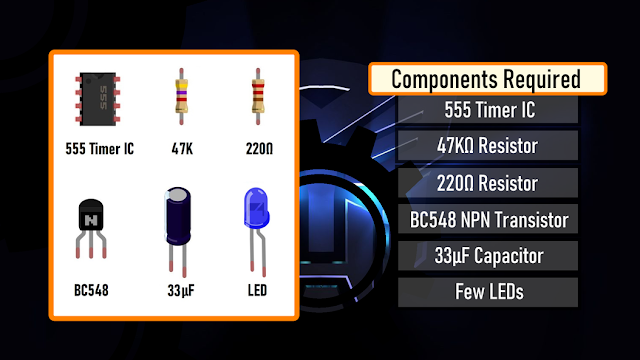

Components Required

For this tutorial you need:

- 1 x 555 Timer IC

- 1 x 47KΩ Resistor

- 1 x 220Ω Resistor

- 1 x BC548 NPN Transistor

- 1 x 33µF Capacitor, and

- 1 x Few Blue LEDs

Quick Recap

In my last tutorial I created a "IC555 Led Fader Module" and explained how the circuit works. In this tutorial, I am going to use the same LED fader circuit to create a fading effect for the eyes of the badge.

So before going ahead, lets do a quick recap and find out how the LED fader circuit works with the help of an animation.

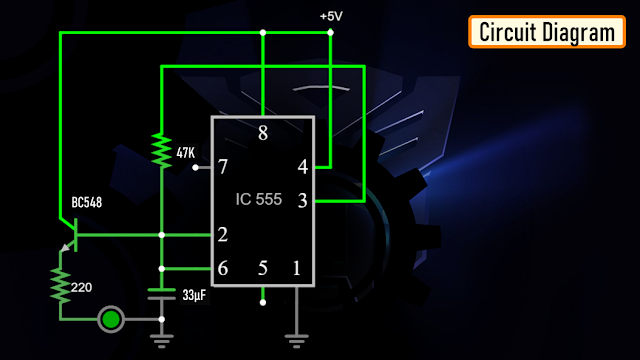

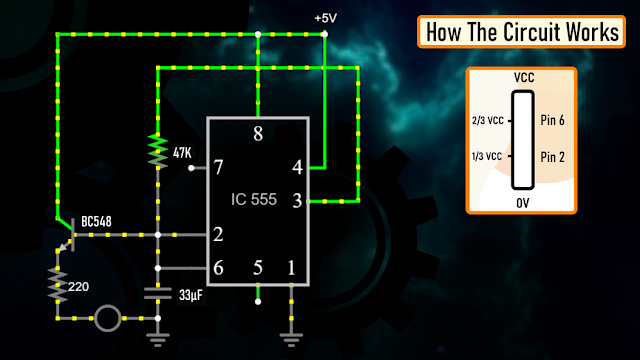

Circuit Diagram

The heart of this circuit is the 555 timer IC.

Pin No.1 of the IC is connected to GND.

By connecting Pin 2 and 6 of the 555 timer IC, we put the IC in astable mode. In astable mode, the 555 timer IC acts as an oscillator (re-triggering itself) generating square waves [PWM Signals] from the output Pin no. 3.

3 other components connect to this junction.

1st one is the 33µF capacitor. The positive pin of the capacitor connects to the junction and the negative pin is connected to the GND.

2nd one is the 47KΩ resistor. One of its legs connects to the junction and the other leg connects to the Output pin, Pin No.3 of the IC.

3rd one is the Base of the BC548 NPN transistor. The collector of the transistor along with Pin 8 and 4 of the IC connects to the +ve terminal. of the battery. The LED along with its current limiting resistor is connected to the Emitter of the transistor.

That's+-

How The Circuit Works

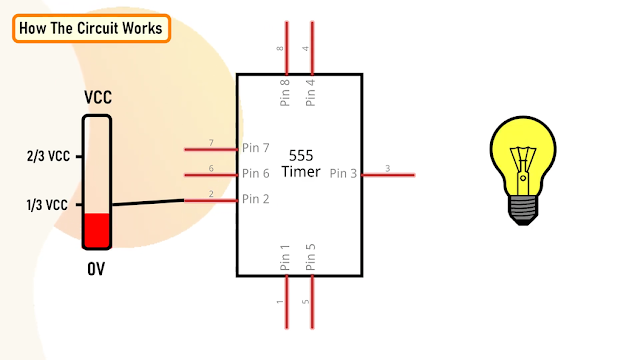

When Pin 2 of the IC detects voltage LESS than 1/3rd of the supply voltage, it turns ON the output on Pin 3.

And, when Pin 6 detects voltage MORE than 2/3rds of the supply voltage, it turns OFF the output.

This is how the trigger pin (Pin2) and the

threshold pin (Pin6) of the 555 timer IC sense voltages and controls the output at Pin 3.

The Capacitor attached to the circuit will be in a discharged state immediately after firing up the circuit.

So, the voltage at Pin 2 will be 0v which is less than 1/3rds of the supply voltage, this will turn ON the output on Pin 3.

Since Pin 3 is looped back to Pin 2, it will start charging the Capacitor via the 47KΩ resistor.

At the same time the base current of the transistor also increases causing the LED to slowly "fade-in".

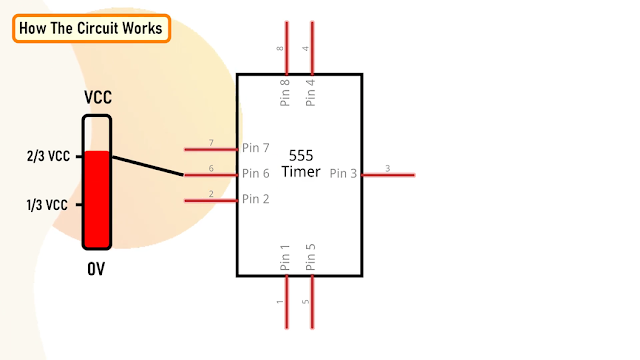

Once the voltage across the capacitor crosses 2/3rds of the supply voltage, Pin 6 turns OFF the output.

This causes the capacitor to slowly discharge causing the base current to fall and hence the LED starts "fading-out".

Once the voltage across the capacitor falls below 1/3rd of the supply voltage, Pin 2 turns ON the output, and the above cycle continues.

You can hook up a multimeter to the circuit to measure the charging and discharging of the capacitor.

Designing The PCB

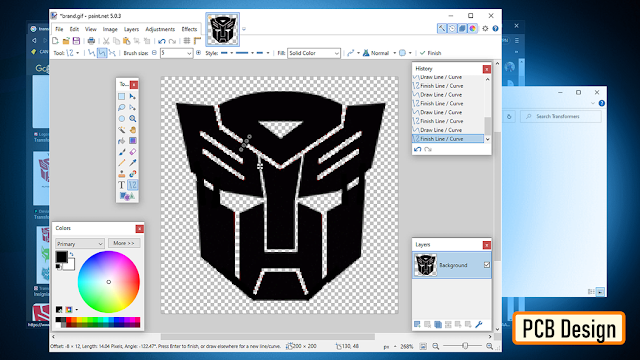

Sorting Out Images

To start the designing process, I need a transparent PNG image of the "Transformers Logo".

So I went online, and did an "image search" and downloaded a black-and-white images of the Transformers Logo.

Now, using the "Paint.Net" application I opened up the PNG file.

The image onscreen will be used for:

1. Creating the border outline of the badge

2. and also for creating the face on top of the top silk layer

To generate the "Border Outline" I need a DXF file.

Looking at the image, we can see that the image is split into multiple parts. If I load this to generate a DXF file it will generate multiple pieces of the PCB. And obviously that's not what I am after. So, I joined all the small pieces into a single image.

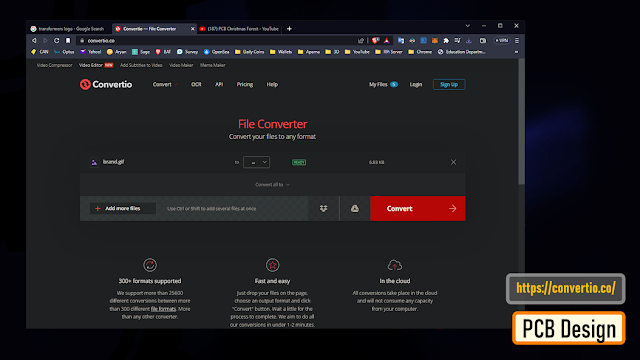

Generating DXF File

Then, I uploaded the images to "https://convertio.co/" to generate the DXF files. This website allows 10 free conversions in a day unless you have a paid account with them.

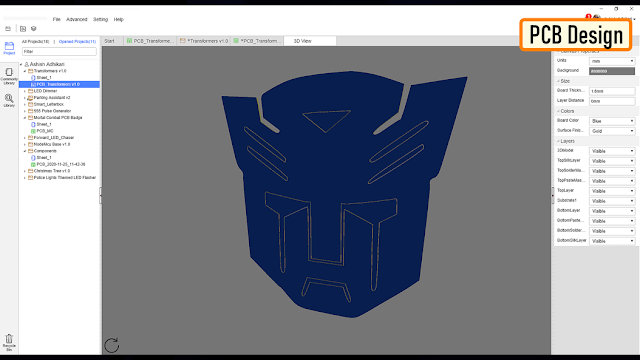

Creating the Badge

Now, lets go ahead and add a "New PCB" to our project and remove the default board outlines.

Then import the DXF files via File > Import > DXF menu. Make sure you have the "BoardOutLine" selected under layers when you import the DXF file.

Now, lets import the image that will go on the Top Silk Layer. Select the "TopSilkLayer" and then import the image and move it inside the board outlines. Before going ahead, lets have a look at how the board looks like in 3D. As we can see the eyes and all other holes still have the blue PCB bits inside. So, let go ahead and remove them from our design.

To do so, select the "MultiLayer" from the "Layers and Objects" panel. Then select "Solid Region" from the "PCB Tools" panel and start drawing the region you want to exclude from your PCB. That's it as easy as that. Checking the PCB in 3D, we can see that the top bit has now a see-through hole in it. I repeated this step, for all other bits that I wanted to excluded from my PCB design.

Once the PCB design was sorted, I added all the electronic components to the board. Since I don't want any hole on my PCB, my choice was to either add SMD components on the board or to design the board in a way that I can solder THT components on it. I chose the second option and added all the THT components "however" without their holes. Instead of the holes I added some rectangles and circles from the "PCB Tools" panel on the "BottomLayer" and then exposed the copper. To finalize the design, I connected all the exposed pads as per the circuit diagram. That's it, all done. So, this is how the final design looks like.

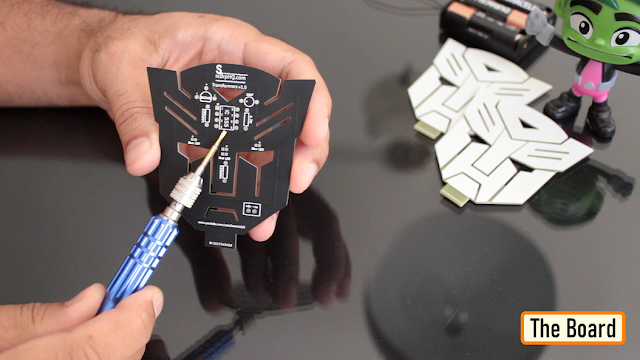

The Board

So this is what came in the mailbag. Have a look at the quality, its absolutely mind-blowing.

At the back of the board are all the exposed copper parts for soldering the electronic components.

As mentioned earlier, I could have designed the board with SMD components, however I wanted to design something that someone with "0" SMD soldering knowledge can also do.

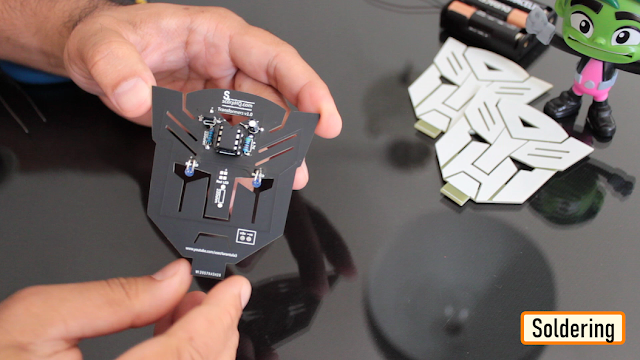

Soldering

Alright, now lets go ahead and solder the components to the board.

Lets first soldered the 555 Timer IC to the board, then lets soldered the two resistors to the board. Next, lets soldered the 33µF Capacitor followed by the NPN transistor to the board.

To conclude the setup lets soldered the 2 x LEDs to the board. You can power this circuit by providing voltage between 5V to 15Vs.

Demo

So, this is how the final setup looks like. You can insert the bottom bit of the badge to a wooden-plank and put this on your desk to give your desk a flashy look.

Thanks

Thanks again for checking my post. I hope it helps you.

If you want to support me subscribe to my YouTube Channel: https://www.youtube.com/user/tarantula3

- Video: https://youtu.be/vlJoQAzjYDo

- Full Blog Post: https://diyfactory007.blogspot.com/2023/05/TransformersPCBBADGE.html

- LED Fader Using 555 Timer IC: https://youtu.be/30wGujPnupw

- LED Fader - With or Without Arduino: Visit https://youtu.be/IIUsdICycOw

- Adjustable Single/Dual LED Flasher Using 555 Timer IC: Visit https://youtu.be/B1URFJywtcI

Other Links:

- Github: https://github.com/tarantula3/Transformers-PCB-BADGE-Autobots

- Simulation: https://tinyurl.com/2qv266bg

- What Is Forward Voltage: https://42electronics.com/blogs/learn-more/what-is-forward-voltage

Support My Work:

- BTC: 1Hrr83W2zu2hmDcmYqZMhgPQ71oLj5b7v5

- LTC: LPh69qxUqaHKYuFPJVJsNQjpBHWK7hZ9TZ

- DOGE: DEU2Wz3TK95119HMNZv2kpU7PkWbGNs9K3

- ETH: 0xD64fb51C74E0206cB6702aB922C765c68B97dCD4

- BAT: 0x9D9E77cA360b53cD89cc01dC37A5314C0113FFc3

- LBC: bZ8ANEJFsd2MNFfpoxBhtFNPboh7PmD7M2

- COS: bnb136ns6lfw4zs5hg4n85vdthaad7hq5m4gtkgf23 Memo: 572187879

- BNB: 0xD64fb51C74E0206cB6702aB922C765c68B97dCD4

- MATIC: 0xD64fb51C74E0206cB6702aB922C765c68B97dCD4

Thanks, ca again in my next tutorial.

Transformers PCB BADGE

*PCBWay community is a sharing platform. We are not responsible for any design issues and parameter issues (board thickness, surface finish, etc.) you choose.

- Comments(0)

- Likes(1)

-

Engineer

Jan 24,2024

Engineer

Jan 24,2024

- 0 USER VOTES

- YOUR VOTE 0.00 0.00

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

More by Ashish Adhikari

More by Ashish Adhikari

-

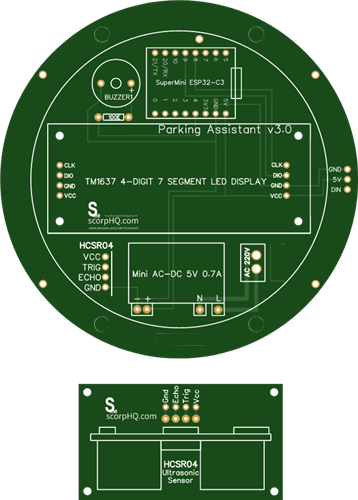

Arduino Parking Assistant V3

The ESP32-C3 Based Parking Assistant is an advanced parking sensor system that utilizes the ESP32-C3...

Arduino Parking Assistant V3

The ESP32-C3 Based Parking Assistant is an advanced parking sensor system that utilizes the ESP32-C3...

-

100 LED Chaser Circuit Using IC555 and CD4017

A Chaser Circuit consists of a clocked IC or other electronic unit like an Arduino that drives an ar...

100 LED Chaser Circuit Using IC555 and CD4017

A Chaser Circuit consists of a clocked IC or other electronic unit like an Arduino that drives an ar...

-

Cute Medusa 3D Printed Humidifier

Humidifiers add moisture to the air. They can help people with dry skin, allergies, and respiratory ...

Cute Medusa 3D Printed Humidifier

Humidifiers add moisture to the air. They can help people with dry skin, allergies, and respiratory ...

-

4x4x4 PCB LED CUBE

Note from PCBWay: This project includes two PCBs, if both need to be produced, please inform your sa...

4x4x4 PCB LED CUBE

Note from PCBWay: This project includes two PCBs, if both need to be produced, please inform your sa...

-

Getting Started With Raspberry Pi Pico

Couple of months ago, I bought a "Raspberry Pi Pico" to get some hands-on experience of it and to cr...

Getting Started With Raspberry Pi Pico

Couple of months ago, I bought a "Raspberry Pi Pico" to get some hands-on experience of it and to cr...

-

Make Your Own 3D Printed Diwali Diyas at Home

Diyas are the heart of major Indian festivals, most notably Diwali, the "Festival of Lights." Lighti...

Make Your Own 3D Printed Diwali Diyas at Home

Diyas are the heart of major Indian festivals, most notably Diwali, the "Festival of Lights." Lighti...

-

Arduino Based 3D Printed Color Adjustable Minecraft Lantern

For this Halloween, I'm fusing the creative blocky world of Minecraft with the spooky glow of the co...

Arduino Based 3D Printed Color Adjustable Minecraft Lantern

For this Halloween, I'm fusing the creative blocky world of Minecraft with the spooky glow of the co...

-

3D Printed Breathing IC555 LED Trophy

This project features a custom 3D-printed 'Mortal Kombat' trophy shell paired with a basic NE555 tim...

3D Printed Breathing IC555 LED Trophy

This project features a custom 3D-printed 'Mortal Kombat' trophy shell paired with a basic NE555 tim...

-

Destiny Internet Ghost - Internet Notifier

The Internet has changed the way we live our lives. From communication, education, banking, entertai...

Destiny Internet Ghost - Internet Notifier

The Internet has changed the way we live our lives. From communication, education, banking, entertai...

-

Liquid level indicator Using ULN2003

A water level indicator detects and indicates the level of water in an overhead tank and relays the ...

Liquid level indicator Using ULN2003

A water level indicator detects and indicates the level of water in an overhead tank and relays the ...

-

All About IC UNL2003

The UNL2003 IC contains 7 High Voltage, High Current NPN Darlington Transistor Arrays each rated at ...

All About IC UNL2003

The UNL2003 IC contains 7 High Voltage, High Current NPN Darlington Transistor Arrays each rated at ...

-

NodeMCU Based: 3D Printed Indoor Gauge Thermometer

Had some time this weekend and a desire to create something new and interesting, so went ahead and c...

NodeMCU Based: 3D Printed Indoor Gauge Thermometer

Had some time this weekend and a desire to create something new and interesting, so went ahead and c...

-

Rechargeable Gothic Lantern

A Gothic Lantern is a captivating piece of lighting that brings the allure of the Victorian Era into...

Rechargeable Gothic Lantern

A Gothic Lantern is a captivating piece of lighting that brings the allure of the Victorian Era into...

-

555 Adjustable Delay On Off Timer Circuit

The 555 timer IC is an integrated circuit (IC) that is used in a variety of timer, delay, pulse gene...

555 Adjustable Delay On Off Timer Circuit

The 555 timer IC is an integrated circuit (IC) that is used in a variety of timer, delay, pulse gene...

-

3D Printed Arduino Halloween Décor

When the full moon is shining and the wolves are howling, it's time for Halloween's spooky spectacle...

3D Printed Arduino Halloween Décor

When the full moon is shining and the wolves are howling, it's time for Halloween's spooky spectacle...

-

All About RCWL-0516 Microwave Radar Motion Sensor

Proximity sensing is a very common application in electronics.There are several ways to accomplish t...

All About RCWL-0516 Microwave Radar Motion Sensor

Proximity sensing is a very common application in electronics.There are several ways to accomplish t...

-

Transformers PCB BADGE

It's been a while, the Autobots have appeared on the silver screen. Finally they are returning to th...

Transformers PCB BADGE

It's been a while, the Autobots have appeared on the silver screen. Finally they are returning to th...

-

LED Fader Using 555 Timer IC

LED Fader Using 555 Timer ICWanted to generate a LED fading effect (fade-in and fade-out) for my upc...

LED Fader Using 555 Timer IC

LED Fader Using 555 Timer ICWanted to generate a LED fading effect (fade-in and fade-out) for my upc...

-

-

mammoth-3D SLM Voron Toolhead – Manual Drill & Tap Edition

136 0 0 -

-

AEL-2011 Power Supply Module

643 0 2 -

AEL-2011 50W Power Amplifier

560 0 2 -

-

-

Custom Mechanical Keyboard

762 0 0 -

Tester for Touch Screen Digitizer without using microcontroller

392 2 2 -

Audio reactive glow LED wristband/bracelet with NFC / RFID-Tags

361 0 1 -

-