|

Autodesk Fusion 360Autodesk

|

|

|

EagleAutodesk

|

Dedicated Control Board for Mobile Robots with Wheels

Introduction

For a long time we developed several prototypes and teaching kits of mobile robots and we always used different modules to build them.

Among these modules, we highlight: module to drive motors, module TP4056 to charge the project's batteries, an Arduino board and a shield for connecting the wires to the Arduino's digital inputs.

This amount of modules often generates problems with bad connections and also makes connections more complex, with more wires. Also, they are not feasible to build a prototype or commercial product.

After all, what to do to reduce the number of modules in the construction of mobile robot teaching kits?

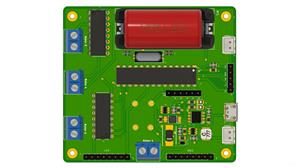

Based on this problem, we developed a circuit board with several features that will allow you to control your mobile robot. See the picture below.

The files for this board are available for download from the PCBWay website. Take advantage now, visit the link, register and get a $5 coupon for you to win 10 free units of this electronic board.

What features have been implemented in this electronic board?

Below we have all the functionalities implemented in the electronic board.

- Charging system for Li-Ion battery with IC TP4056,

- DC-DC Boost Converter Circuit with 6V output,

- L293D Driver Circuit for the Motors, and

- Arduino Standalone Circuit with the ATMEGA328P.

Below we will present in detail all these functionalities implemented from the electronic schematic of the project.

Control Board Electronic Schematic

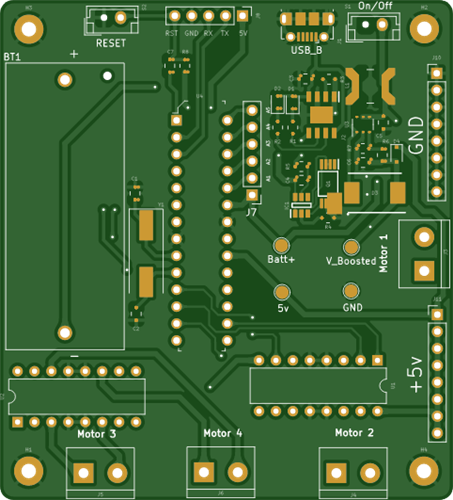

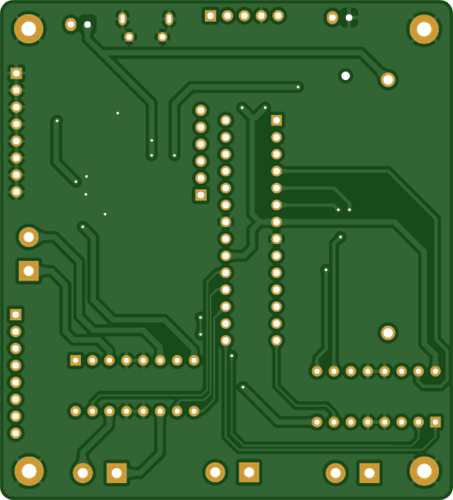

The electronic circuit was divided into 4 parts: battery charging circuit, motor drive drivers, ATMEGA328P control circuit, circuit connectors and fixing holes. Below we have the electronic schematic of the project.

Next, we will discuss each part of the circuit and how it works in the mobile robot control process.

Mobile Robot Battery Charging Circuit

Many users who program mobile robots constantly need to remove the batteries from the project to charge it. This process requires opening the robot and an external charger for charging.

In addition, 2 18650 batteries are usually used to supply a voltage of 7.4V for project power. This requires more internal space and financial cost of 2 batteries.

How to solve this problem?

The first step for this was to create a circuit for charging Li-Ion battery with IC TP4056. The circuit structure is shown in the figure below.

Before implementing the charging circuit, we want to use only 1 3.7V Li-Ion 16340 battery to power the project.

In addition to avoiding the use of 2 18650 batteries, it will allow us to reduce the space consumed in the electronic board structure and in the prototype.

However, how do we supply the ATMEGA328P chip with +5V and the motors with +6V?

This question will be answered below.

First, we implement the charging circuit with IC TP4056. It will be used to control and transfer energy to the 16340 Li-Ion battery.

In addition to it, we use the DW01-A CI to ensure safety against overloads and short circuits during the battery charging process. In the electronic diagram of the figure above we have the battery represented by the BT1 element.

After the battery we insert a JST connector to insert an ON/OFF button. This allows you to turn the project control circuit on and off. Now, let's go back and answer the previous question: how to power the ATMEGA328P chip with +5V and the motors with +6V?

This lifting process is done through the circuit below. What circuit is this and how does it work?

The circuit above is a boost type DC-DC converter. It has the purpose of raising the input DC voltage to another DC voltage level at the output.

For this project we are raising the battery voltage from +3.7V to +6V.

All of the above elements were calculated to provide this voltage. The MT3608 CHIP is the circuit's STEP-UP converter. Access the datasheet through this link.

At the output of the +6V power circuit, we insert an SS315 diode to provide a voltage drop of 0.95V. This allows us to obtain a voltage of approximately +5V to power the control circuit of the ATMEGA328P.

Control Circuit with ATMEGA328P Microcontroller

The ATMEGA328P Microcontroller circuit is shown below.

Several microcontroller digital pins were used to control the pins of the 2 L293D drivers.

L293D Driver for the Motor

Next, we have the electronic schematic shown in the figure below. Each driver was used to control 2 motors. This therefore allows the electronic board to be used to control 2- to 4-wheel mobile robots.

Finally, we created a way to monitor the project's power battery.

Mechanism for Monitoring Battery Voltage

On several devices, such as notebooks and cell phones, for example, it is possible to observe the battery capacity level. This allows us to know when is the ideal time to carry out a new load.

With that in mind, we created a means to implement this. To do this, we connect the battery output to the A0 terminal of the ATMEGA328P Microcontroller.

From the input voltage it is possible to create a function and inform the battery capacity between 0% and 100%. We have determined a minimum voltage of 3..2V and a maximum voltage of 4.2V for 100%. Whenever the battery is close to this value, it is possible to generate an alert to the user to charge the project's battery.

Finally, we provide some power and connection pins to the ATMEGA328P Microcontroller pins.

Pins for Power and Connection of other Devices

How to connect an ultrasonic sensor to this electronic board or an extra button, for example?

This can be done through the male headers connector pins shown below.

In total there are 4 connectors. Among them we have:

1 connector with voltage potential 0V,

1 connector with voltage potential of +5V, and

1 connector with access to pins A1, A2, A3, A4, and A5.

From these 3 connectors we can connect several sensors and other devices that will facilitate the navigation of the mobile robot.

In addition to these pins, we have a connector to transfer the code to the ATMEGA328P Microcontroller with access to the +5V, GND, TX, RX, and RESET pins.

See electronic schematic below.

Below we present the complete structure of the electronic board of the project.

Electronic Board Structure for Mobile Robot Control

All images are inserted in this project.

All files for this project are available in this PCBWay Shared Projects Comunitye. You will have access to the following files:

- Electronic schematic,

- Gerber file,

- List of materials,

- 3D file of the electronic board for prototyping, and

- Pick and Place file for SMD assembly.

Future Updates

All files are available for download and you can get 10 free PCBWay units. To earn the $5 coupon and receive the 10 units you must access this link, create your account and order your plates for free.

In future updates we will develop a new version with a USB flashing circuit to facilitate the direct transfer of code from the computer to the development board.

All future PCB updates are available soon at the end of this article.Take advantage now and get 10 free units of this Arduino at your home. Click here and enjoy.

Dedicated Control Board for Mobile Robots with Wheels

*PCBWay community is a sharing platform. We are not responsible for any design issues and parameter issues (board thickness, surface finish, etc.) you choose.

Raspberry Pi 5 7 Inch Touch Screen IPS 1024x600 HD LCD HDMI-compatible Display for RPI 4B 3B+ OPI 5 AIDA64 PC Secondary Screen(Without Speaker)

BUY NOW

ESP32-S3 4.3inch Capacitive Touch Display Development Board, 800×480, 5-point Touch, 32-bit LX7 Dual-core Processor

BUY NOW

Raspberry Pi 5 7 Inch Touch Screen IPS 1024x600 HD LCD HDMI-compatible Display for RPI 4B 3B+ OPI 5 AIDA64 PC Secondary Screen(Without Speaker)

BUY NOW- Comments(0)

- Likes(1)

Log in to post comments.

Log in to post comments.

-

Engineer

Nov 30,2022

Engineer

Nov 30,2022

- 0 USER VOTES

- YOUR VOTE 0.00 0.00

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

More by Silícios Lab silicioslab

More by Silícios Lab silicioslab

-

Electronic Enclosure for Programmable Logic Controller

The housing developed for programmable logic controllers is a practical and efficient solution for t...

Electronic Enclosure for Programmable Logic Controller

The housing developed for programmable logic controllers is a practical and efficient solution for t...

-

Payment PCB for machines and services

IntroductionIn many commercial establishments, hospitals and other places, there are video game equi...

Payment PCB for machines and services

IntroductionIn many commercial establishments, hospitals and other places, there are video game equi...

-

Relay High Power Printed Circuit Board

IntroductionEfficient management of electrical loads is essential for optimizing performance and saf...

Relay High Power Printed Circuit Board

IntroductionEfficient management of electrical loads is essential for optimizing performance and saf...

-

Weather gadget with clock through ESP8266

IntroductionImagine a device that combines technology with an elegant design, bringing functionality...

Weather gadget with clock through ESP8266

IntroductionImagine a device that combines technology with an elegant design, bringing functionality...

-

ESP32 MPU6050 Monitor

IntroductionVarious industrial equipment is essential for the adequate production of products, parts...

ESP32 MPU6050 Monitor

IntroductionVarious industrial equipment is essential for the adequate production of products, parts...

-

Digital Speedometer for Bicycles

IntroductionCycling, increasingly popular both as a recreational activity and as a means of transpor...

Digital Speedometer for Bicycles

IntroductionCycling, increasingly popular both as a recreational activity and as a means of transpor...

-

How to measure weight with Load Cell and HX711

IntroductionThe purpose of this project is to develop a printed circuit board (PCB) that allows weig...

How to measure weight with Load Cell and HX711

IntroductionThe purpose of this project is to develop a printed circuit board (PCB) that allows weig...

-

Electronic Enclosure applied for electronic projects

IntroductionWhen designing electronics, the enclosure plays a crucial role that is often overlooked....

Electronic Enclosure applied for electronic projects

IntroductionWhen designing electronics, the enclosure plays a crucial role that is often overlooked....

-

IoT Indoor system with ESP32 to monitor Temperature, Humidity, Pressure, and Air Quality

IntroductionAir quality, temperature, humidity and pressure are essential elements to ensure healthy...

IoT Indoor system with ESP32 to monitor Temperature, Humidity, Pressure, and Air Quality

IntroductionAir quality, temperature, humidity and pressure are essential elements to ensure healthy...

-

WS2812B RGB LED Controller with ESP8266 via WiFi

IntroductionWS2812b addressable RGB LEDs are devices widely used in lighting projects. They are foun...

WS2812B RGB LED Controller with ESP8266 via WiFi

IntroductionWS2812b addressable RGB LEDs are devices widely used in lighting projects. They are foun...

-

Electronic Board for Cutting Electrical Power to Devices and Machines

IntroductionAn energy saving system for cutting electrical energy in machines is a fundamental piece...

Electronic Board for Cutting Electrical Power to Devices and Machines

IntroductionAn energy saving system for cutting electrical energy in machines is a fundamental piece...

-

PCB Board Home Automation with ESP8266

IntroductionThe incorporation of the ESP8266 module into home automation represents a significant ad...

PCB Board Home Automation with ESP8266

IntroductionThe incorporation of the ESP8266 module into home automation represents a significant ad...

-

Dedicated Control Board for Mobile Robots with Wheels

IntroductionFor a long time we developed several prototypes and teaching kits of mobile robots and w...

Dedicated Control Board for Mobile Robots with Wheels

IntroductionFor a long time we developed several prototypes and teaching kits of mobile robots and w...

-

Traffic turn signal for bicycles

IntroductionDoes every project with electronic logic need a Microcontroller or Arduino to be develop...

Traffic turn signal for bicycles

IntroductionDoes every project with electronic logic need a Microcontroller or Arduino to be develop...

-

Mini Arduino with ATTINY85

Do you know the ATTINY85 microcontroller? This article has news and a gift for you. Many people deve...

Mini Arduino with ATTINY85

Do you know the ATTINY85 microcontroller? This article has news and a gift for you. Many people deve...

-

Christmas Tree

The tree used to signal light of Christmas.

Christmas Tree

The tree used to signal light of Christmas.

-

IoT Access control and communication system with Raspberry Pi/PC using ESP32

IntroductionIn the world of automation and the Internet of Things (IoT), access control systems have...

IoT Access control and communication system with Raspberry Pi/PC using ESP32

IntroductionIn the world of automation and the Internet of Things (IoT), access control systems have...

-

Electronic Enclosure applied for electronic devices

IntroductionWhen designing electronics, the enclosure plays a crucial role that is often overlooked....

Electronic Enclosure applied for electronic devices

IntroductionWhen designing electronics, the enclosure plays a crucial role that is often overlooked....

-

Electronic Enclosure for Programmable Logic Controller

The housing developed for programmable logic controllers is a practical and efficient solution for t...

Electronic Enclosure for Programmable Logic Controller

The housing developed for programmable logic controllers is a practical and efficient solution for t...

-

Payment PCB for machines and services

IntroductionIn many commercial establishments, hospitals and other places, there are video game equi...

Payment PCB for machines and services

IntroductionIn many commercial establishments, hospitals and other places, there are video game equi...

-

Relay High Power Printed Circuit Board

IntroductionEfficient management of electrical loads is essential for optimizing performance and saf...

Relay High Power Printed Circuit Board

IntroductionEfficient management of electrical loads is essential for optimizing performance and saf...

-

Weather gadget with clock through ESP8266

IntroductionImagine a device that combines technology with an elegant design, bringing functionality...

Weather gadget with clock through ESP8266

IntroductionImagine a device that combines technology with an elegant design, bringing functionality...

-

ESP32 MPU6050 Monitor

IntroductionVarious industrial equipment is essential for the adequate production of products, parts...

ESP32 MPU6050 Monitor

IntroductionVarious industrial equipment is essential for the adequate production of products, parts...

-

Digital Speedometer for Bicycles

IntroductionCycling, increasingly popular both as a recreational activity and as a means of transpor...

Digital Speedometer for Bicycles

IntroductionCycling, increasingly popular both as a recreational activity and as a means of transpor...

-

How to measure weight with Load Cell and HX711

IntroductionThe purpose of this project is to develop a printed circuit board (PCB) that allows weig...

How to measure weight with Load Cell and HX711

IntroductionThe purpose of this project is to develop a printed circuit board (PCB) that allows weig...

-

Electronic Enclosure applied for electronic projects

IntroductionWhen designing electronics, the enclosure plays a crucial role that is often overlooked....

Electronic Enclosure applied for electronic projects

IntroductionWhen designing electronics, the enclosure plays a crucial role that is often overlooked....

-

IoT Indoor system with ESP32 to monitor Temperature, Humidity, Pressure, and Air Quality

IntroductionAir quality, temperature, humidity and pressure are essential elements to ensure healthy...

IoT Indoor system with ESP32 to monitor Temperature, Humidity, Pressure, and Air Quality

IntroductionAir quality, temperature, humidity and pressure are essential elements to ensure healthy...

-

WS2812B RGB LED Controller with ESP8266 via WiFi

IntroductionWS2812b addressable RGB LEDs are devices widely used in lighting projects. They are foun...

WS2812B RGB LED Controller with ESP8266 via WiFi

IntroductionWS2812b addressable RGB LEDs are devices widely used in lighting projects. They are foun...

-

Electronic Board for Cutting Electrical Power to Devices and Machines

IntroductionAn energy saving system for cutting electrical energy in machines is a fundamental piece...

Electronic Board for Cutting Electrical Power to Devices and Machines

IntroductionAn energy saving system for cutting electrical energy in machines is a fundamental piece...

-

PCB Board Home Automation with ESP8266

IntroductionThe incorporation of the ESP8266 module into home automation represents a significant ad...

PCB Board Home Automation with ESP8266

IntroductionThe incorporation of the ESP8266 module into home automation represents a significant ad...

-

-

-

-

Modifying a Hotplate to a Reflow Solder Station

1007 1 6 -

MPL3115A2 Barometric Pressure, Altitude, and Temperature Sensor

544 0 1 -

-

Nintendo 64DD Replacement Shell

448 0 2 -

V2 Commodore AMIGA USB-C Power Sink Delivery High Efficiency Supply Triple Output 5V ±12V OLED display ATARI compatible shark 100W

1276 4 2 -

How to measure weight with Load Cell and HX711

765 0 3